A method to increase the rate of hydrogenation - a chemical reaction used in many industrial applications from food production to petrochemicals and pharmaceutical manufacturing - has been developed by a team of NUS researchers.

By using their new approach, the researchers were able to increase the rate of ethylene hydrogenation by more than five times compared to standard industrial rates; a level which could deliver both higher yields for industry and reduced environmental impacts.

Hydrogenation is a process involving the addition of hydrogen to unsaturated chemical bonds and is commonly used to solidify, preserve or purify many products, raw materials, or ingredients.

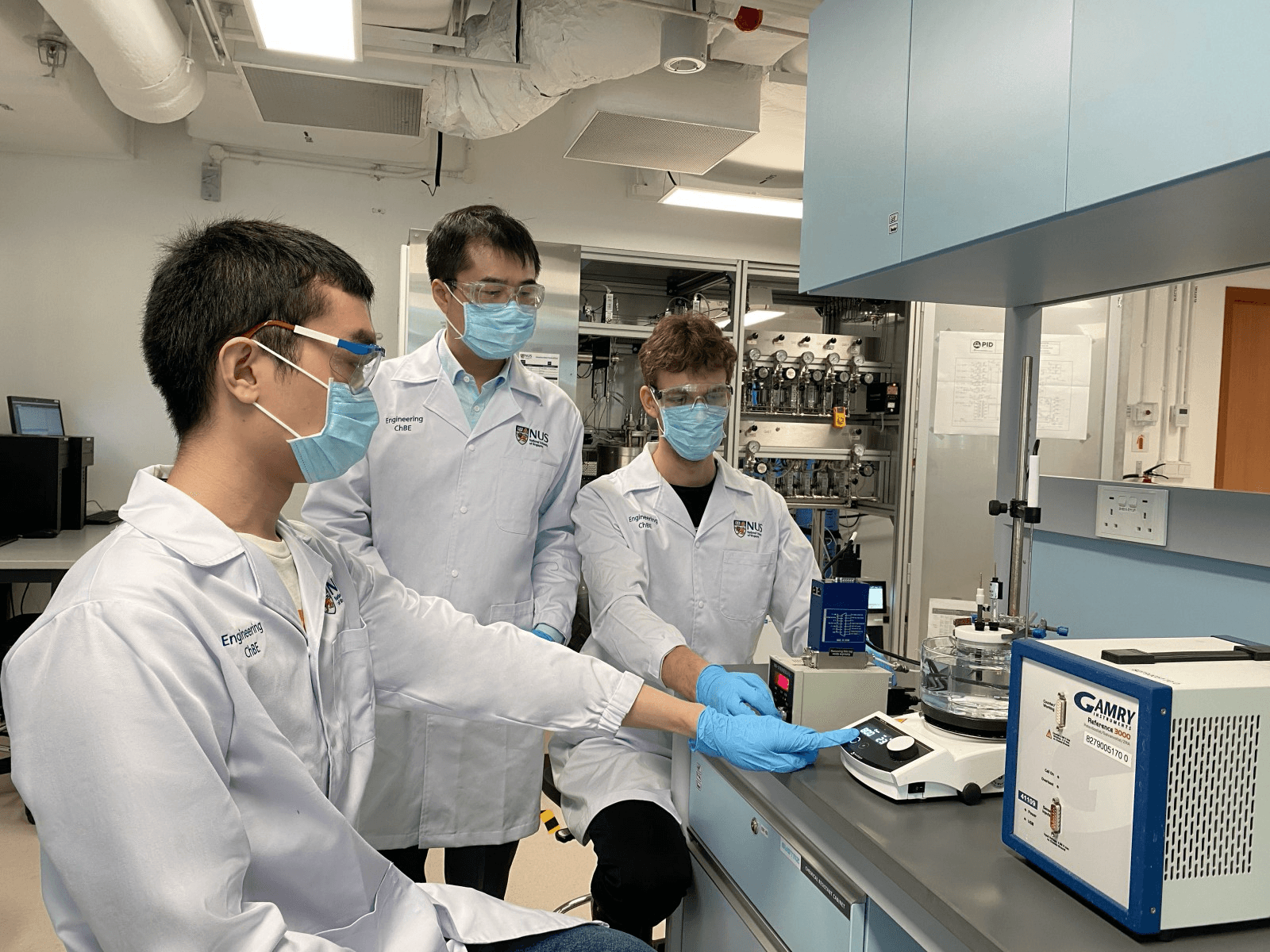

The process typically uses a static solid catalyst to speed up the reaction. However, the technique developed by NUS researchers applies oscillating electric potentials to a commercial hydrogenation catalyst, which they found dramatically increased the hydrogenation rate of ethylene to ethane.

"Such enhancements in the rates or selectivity of chemical reactions are instrumental in making a chemical process more efficient," said Associate Professor Yan Ning from the Department of Chemical and Biomolecular Engineering who led the research team.

"Our work demonstrates a more direct and cost-effective way of optimising catalyst performance that is beyond conventional methods."

For more on this story, click here to go to NUS News.