A novel, lightweight shoulder support exoskeleton with for industrial workers who perform overhead tasks.

Shoulder injuries rank as the second most prevalent injuries in the workplace. In sectors such as construction and manufacturing, workers frequently engage in tasks demanding shoulder flexion, such as lifting heavy objects overhead, wielding tools at elevated angles, and installing fixtures or components above head height. Given the recurrent nature of these actions and their associated risks, there's a pressing need for an assistive solution. We have developed a novel shoulder support exoskeleton that assists the shoulder joint in these type of tasks. We have designed both passive and active versions of the exoskeleton design.

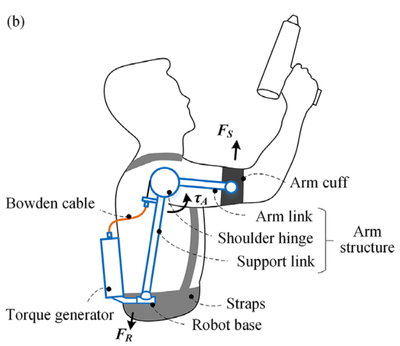

(a) The structure of the spring-cam mechanism. (b) When the arm is raised up ( $\alpha$ is close to 180$^\circ$ ), the spring is not compressed ( $F_1$ is zero) and the force of cable B ( 𝐹2 ) is zero. (c) If 𝛼 is around 90∘ , the spring is compressed ( $F1$ is large), since the force arms ( $r_1$ and $r_2$ ) are almost equal, $F_2$ is also large. (d) When the user puts down the arm ( $\alpha$ is around zero), the spring is fully compressed ( $F1$ reaches the maximum value), however since $r_1$ is much smaller than $r_2$ , $F_2$ can be small. (e) Test bench to validate the assistive torque output. (f) Assistive torque of the torque generator (and the load torque on shoulder) as a function of the shoulder flexion angle. The load torque is estimated by Van Engelhoven et al. $^1$ for 95% males (arm mass 6.2 kg) holding a tool of 2.25 kg (close to the tool weight in our experiments).