A team of researchers from NUS Engineering has developed a new, low energy and cost-effective approach to wastewater purification. The system, which operates on low electrical power, does not generate secondary waste, such as sludge that typically requires costly residual waste processing, and can remove up to 99 percent recalcitrant impurities from wastewater.

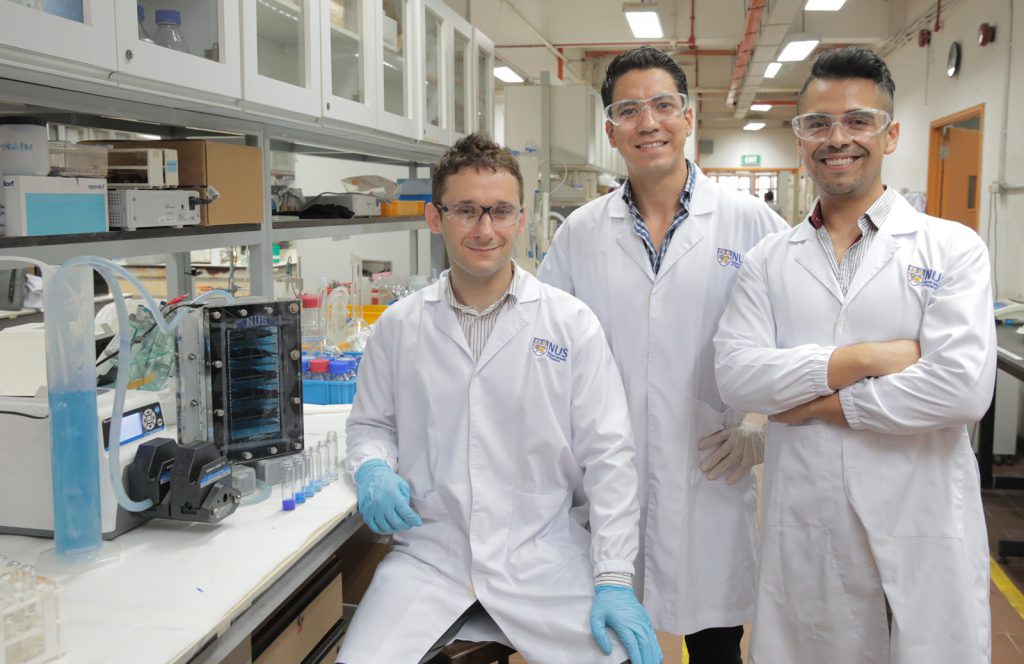

Led by Assistant Professor Olivier Lefebvre from NUS Civil & Environmental Engineering, and a Principal Investigator at NUS Engineering's Centre for Water Research, the team believes the environmentally-friendly invention can help "to raise the overall standard of industrial wastewater treatment". The system uses electrochemistry to treat water and wastewater, and does not require chemicals to be physically added to the system. This means that the wastewater produced by manufacturing industries could be on a constant loop of reusable water.

In 2016, the global market for wastewater recycling and reuse reached nearly US$12.2 billion, and it is expected to reach over US$22 billion by 2021, at an estimated compound annual growth of about 13 percent. Besides benefitting farmland, electronics and pharmaceutical industries, the new electrochemical system developed by the NUS Engineering researchers could potentially be utilised by heavy manufacturing industries that require ultrapure water for their processes, such as mining, oil and gas, and textile industries, and the shipping industry for the disinfection of problematic ballast water from ships. It could also be applied to treat micropollutants in domestic wastewater, as well as manage water purity in the various outdoor environments, for instance, controlling algal growth in water bodies and purifying landfill leachate.

"Electrochemistry is appearing more and more as a technology for the future. It has the power to create a long-term sustainable environment," said Asst Prof Lefebvre. The NUS Engineering team, who has been working on the system since July 2015, applied for two patents for the technology used in the electrochemical system. They are testing the system on more types of industrial wastewater to further refine the design and optimise the efficiency of the system and will develop superior graphene electrodes that could speed up the system's purification process. The researchers are also looking to collaborate with industry partners to commercialise the electrochemical system.