A breakthrough discovery by researchers at CDE could lead to a greener and cheaper method for purifying ethylene, a gas often said to be the world's most important and most widely-used petrochemical.

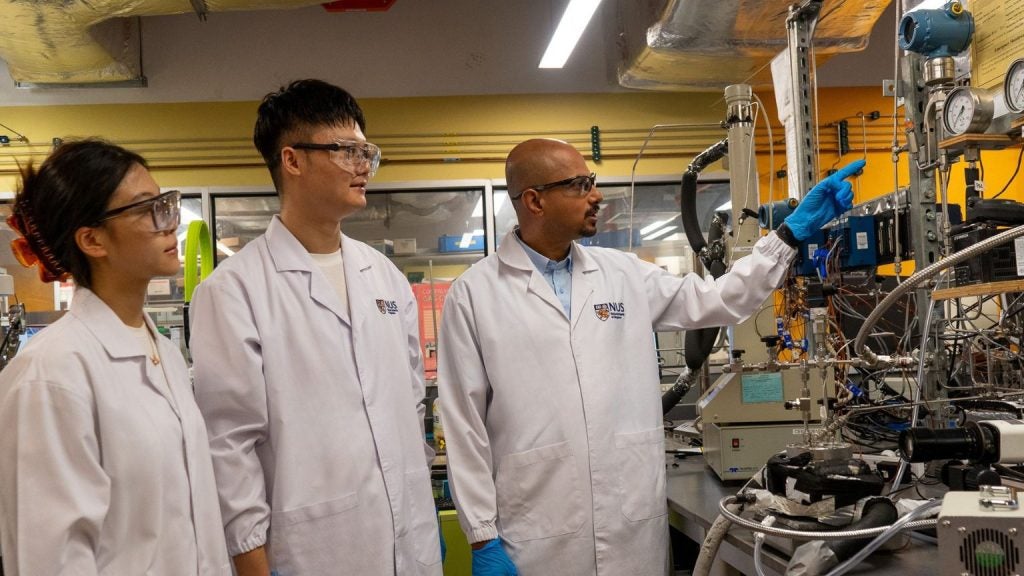

The team led by Assistant Professor Zhang Sui (Dept of Chemical and Biomolecular Engineering) developed a low-cost zinc-based filter that in a single-step process removes impurities like ethyne and ethane from raw ethylene produced through industrial steam cracking.

Polymer-grade ethylene (i.e. with a purity >99.99%) is an essential raw material in making a wide range of rubbers and plastics - from food packing to car components and medical devices - as well as products as diverse as anti-freeze and chewing gum

However, current methods for purifying ethylene using distillation and catalytic conversion involve very low temperatures and high pressures, which means using complex machinery and is very energy intensive.

The researchers say that using a simple filter at ambient temperatures makes the purification process much more straightforward, cheaper and greener.

Until now, the challenge in creating such a filter has been that so-called C2 hydrocarbons - namely ethylene (C2H4), ethyne (C2H2) and ethane (C2H6) - share very similar molecular structures and properties.

The team's breakthrough filter is made from zinc salt formed into a porous structure known as a Metal Organic Framework (MOF), which the researchers say has been proven under laboratory tests to be as effective as current purification methods.

MOFs are a recently developed and fast-growing class of materials, whose properties such as high porosity, robust structures, diverse composition and easy scalability are finding a rapidly-expanding range of applications and functions.

"The excellent performance of our zinc-based MOF filter is mainly attributed to its customised pore structure," said Asst Prof Zhang. "This permits the separator to efficiently trap both ethyne (C2H2) and ethane (C2H6) by specific bonding and molecular shape matching at the same time."

The research team's discovery was published recently in Angewandte Chemie, a journal of the German Chemical Society (GDCh). The study was conducted primarily at NUS, with input from researchers at the University of Amsterdam in the Netherlands and Guangxi University in China.

If the filter can be applied at an industrial scale, Asst Prof Zhang said, "it could revolutionise the hydrocarbon separation process, significantly reducing energy consumption, carbon emissions, and operational costs".

The research team says the next step in commercialising the filter technology is to transform the lab-developed MOF filter into a membrane that can be used in industry.

Furthermore, they say, the research involved in developing the ethylene filter opens the possibility of developing other advanced porous materials that could simplify the process of separating other chemically complex gases.

| Ethylene: A critical chemical

A colourless, flammable gas, ethylene has been dubbed the "world's most important chemical". Considered a basic chemical building block, ethylene is produced naturally by plants and some microbes and is given off by fruit as it ripens. For industrial production at scale however, ethylene is extracted in energy-intensive steam crackers either from crude oil or natural gas and is used in producing a vast range of products and chemicals - from plastics to antifreeze solutions and solvents. Purified polymer-grade ethylene is the foundation for making plastics used in thousands of consumer and industrial goods, from car parts to mattresses, and is a key ingredient in vinyl products such as water pipes, medical equipment and shoe soles. It is also used to make polystyrene foam insulation and synthetic rubber for car tyres, and is processed into polyethylene - used in trash bags and food packaging - as well as polyester used in textiles and water bottles. In 2021 global production of ethylene amounted to more than 214 million metric tons, an increase of 15 per cent in three years. Singapore currently produces about six million metric tons a year of ethylene, just under three per cent of the global total. |