An ultra-stretchable, self-healing, liquid metal material developed by researchers at CDE could revolutionise the world of wearable tech and smart devices, opening up new possibilities in healthcare, patient rehabilitation, soft robotics and a range of other fields.

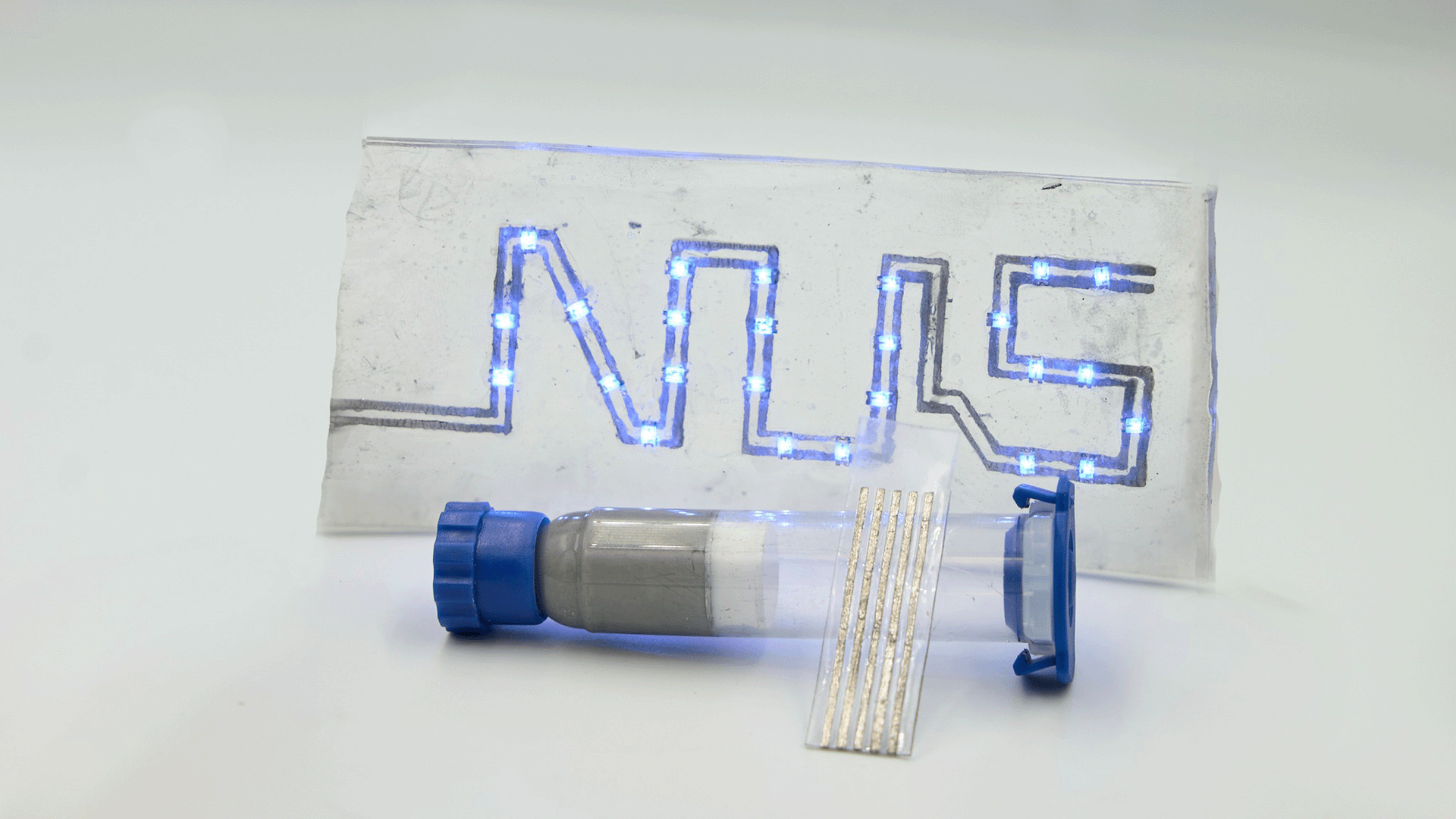

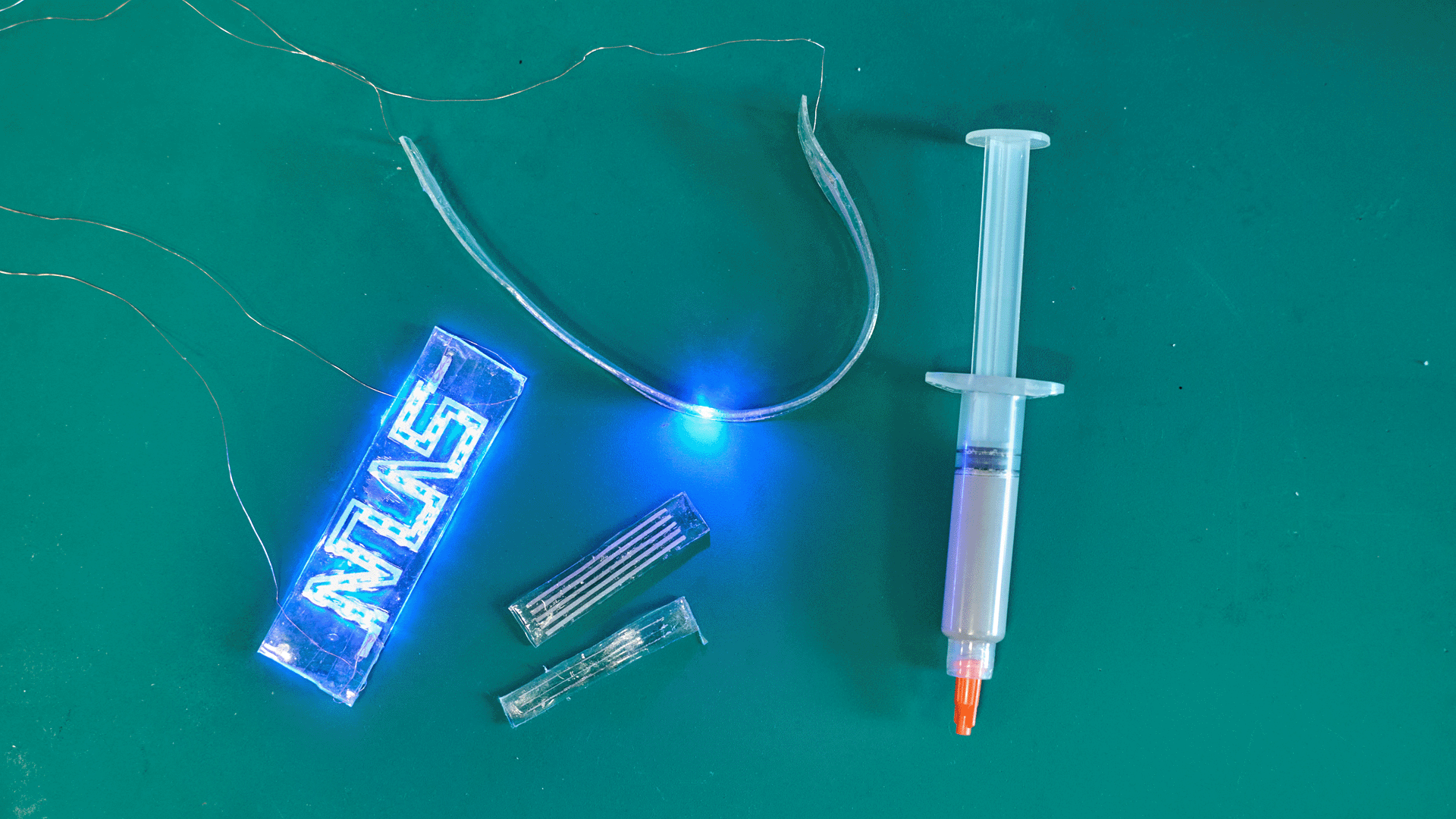

Named BiLiSC - short for Bilayer Liquid-Solid Conductor - the material boasts an astonishing ability to stretch up to 22 times its original length while maintaining its electrical conductivity.

Wearable technology has long been hailed for its potential to transform healthcare monitoring and improve the efficiency of smart devices.

However, innovations in the field of wearables have often been limited by rigid and fragile electronic circuits which lack the durability needed to cope with the stresses and strains placed on them from daily activities.

Professor Lim Chwee Teck (Dept of Biomedical Engineering), the leader of the research team, said BiLiSC could finally eliminate these constraints.

"We developed this technology in response to the need for circuitry with robust performance, functionality, and yet 'unbreakable' for next-generation wearable, robotic, and smart devices," said Prof Lim, who is also Director of the NUS Institute for Health Innovation & Technology (iHeathtech).

The breakthrough was first reported in the journal Advanced Materials.

BiLiSC consists of two layers: the first layer is a self-assembled pure liquid metal, providing high conductivity even under extreme strain, reducing energy loss during power and signal transmission. The second layer is a composite material containing liquid metal microparticles, capable of repairing itself after breakage.

The unique electrical-mechano properties of the material ensures a comfortable and effective interface between humans and devices.

Furthermore, BiLiSC possesses self-healing properties, enabling it to repair itself almost instantly in the event of damage, thus ensuring electronic and functional integrity.

The material's versatility is already apparent, with researchers demonstrating its application in various electrical components for wearable electronics, including pressure sensors, interconnections, wearable heaters, and antennas for wireless communication.

Laboratory experiments showcased a robotic arm with BiLiSC interconnections, detecting and responding swiftly to minute pressure changes while maintaining signal transmission integrity during bending and twisting motions.

Looking ahead, the research team is focused on refining BiLiSC and streamlining its production process to reduce costs and enhance precision.