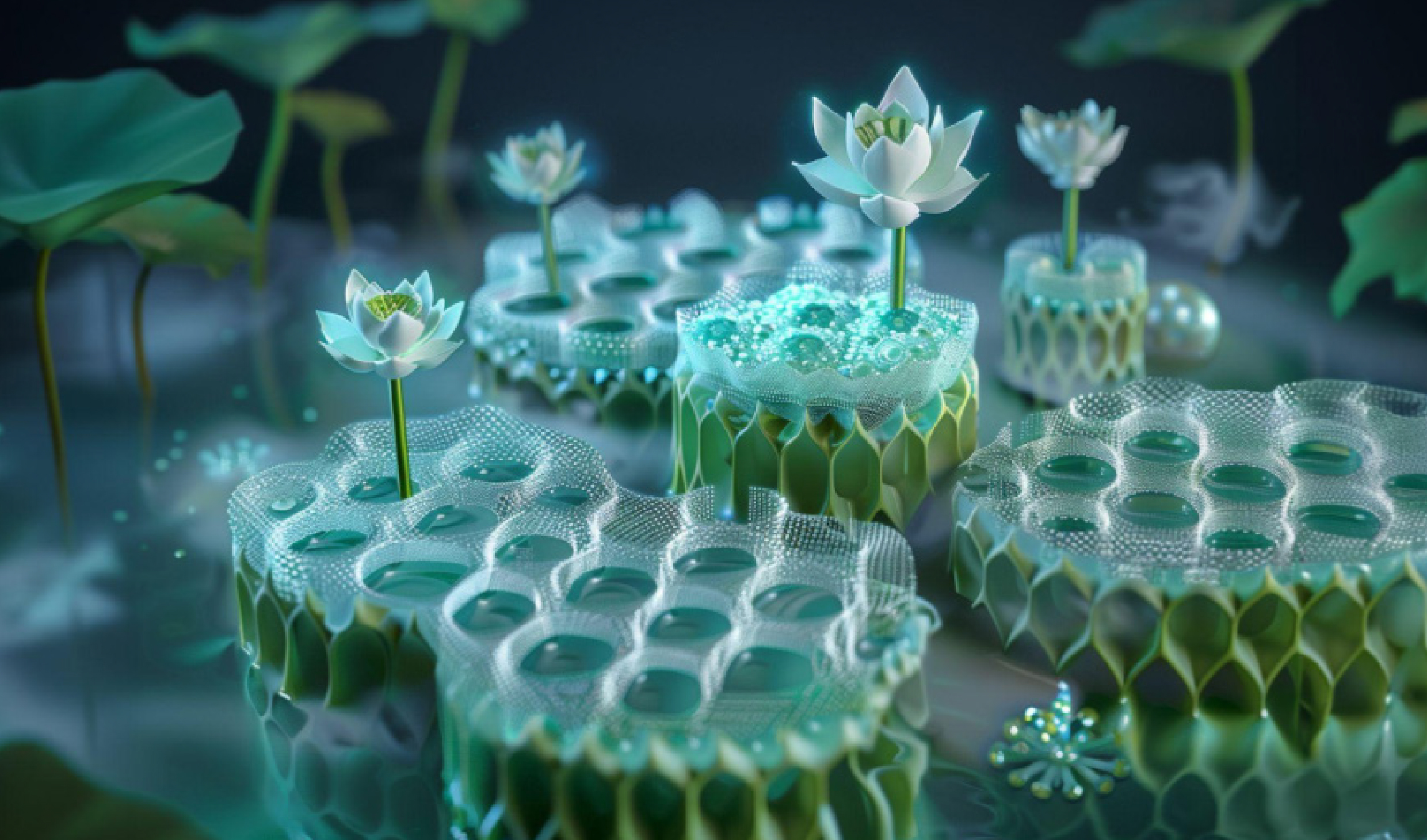

Learning from the lotus leaf

Follow CDE

PDF Download

Inspired by the lotus leaf, the ‘eAir’ sensor achieves near-ideal pressure sensing and is applicable in diverse liquid environments, including those involved in medical settings.

Being able to adapt to varying levels of pressure adeptly is a highly sought-after trait. More so for pressure sensors.

Sensitive and reliable pressure sensors can help extend the human senses in many applications. In medicine, many devices now depend on accurate and stable pressure measurements to function reliably. From ensuring the optimal function of sleep apnea machines to delivering precise drug dosages through infusion pumps or measuring in vivo blood pressure, pressure sensors underpin many healthcare applications — and better sensors translate to improved outcomes.

Drawing inspiration from the superhydrophobic nature of lotus leaves, a research team led by Associate Professor Benjamin Tee from the Department of Materials Science and Engineering at the College of Design and Engineering, National University of Singapore (NUS) and the NUS Institute for Health Innovation & Technology has developed a novel aero-elastic pressure sensor called ‘eAir’.

The team’s sensor enhances precision and reliability across medical applications, from enabling tactile feedback during laparoscopic surgeries to improving patient experiences by providing a less invasive means of monitoring intracranial pressure.

The team’s findings were published in the journal Nature Materials on 17 August 2023.

Associate Professor Benjamin Tee took a page from nature to develop ‘eAir’, a pressure sensor that provides vital feedback in medical settings.

From lotus leaf to laboratory

Conventional pressure sensors, such as those relying on piezo-based, solid-state materials like polymers, are well-developed but often struggle with accuracy in water-based environments. Such sensors are also typically made from mechanically inflexible materials.

To craft sensitive, water-loving pressure sensors, the researchers took a leaf out of nature’s book — one that is attached to the lotus plant, which effortlessly sheds water and dirt despite calling murky ponds home. This uncanny ability is owed to micro- and nanostructures on the leaves’ surface, which trap a thin layer of air, minimising the contact area for water. This air layer is also highly sensitive to pressure.

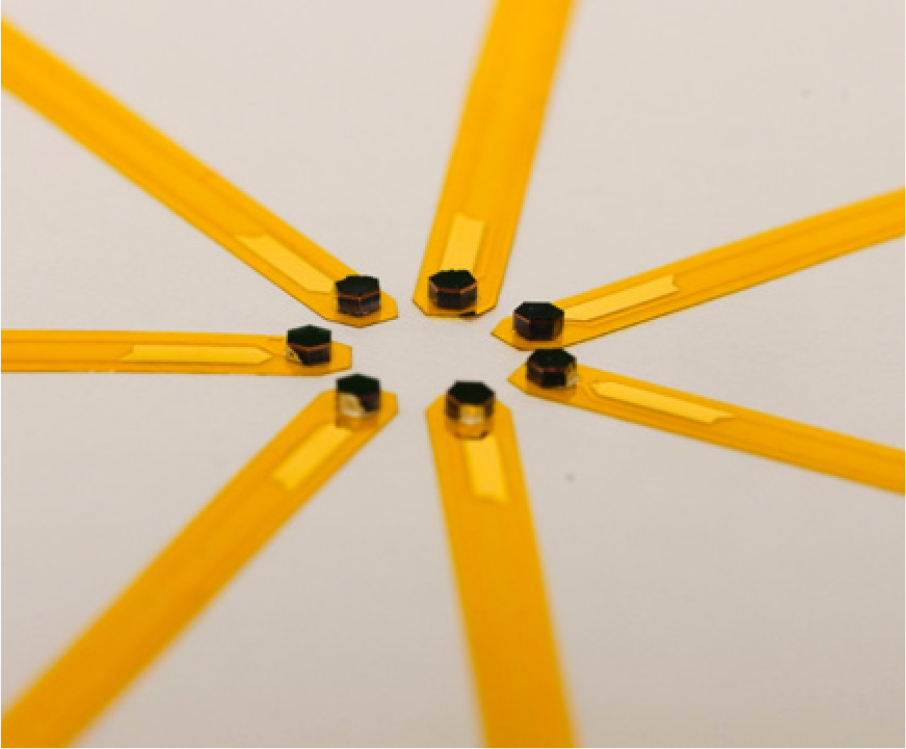

Emulating the structures on a lotus leaf’s surface, the researchers adorned their novel sensing device with myriad microscopic, domed-tipped pillars — coated with silicone oil, organised in an array structure and housed in hexagon-walled chambers — all of which contribute to reducing the surface friction on the electrode to near zero.

“This ultra-slippery surface means that eAir is highly linear and very sensitive. It exhibits low hysteresis, which is the error in sensing between the applied pressure cycles,” says Assoc Prof Tee.

"It’s like a capacity meter, which can detect minute pressure changes — much like the sensitivity of a lotus leaf to the extremely light touch of a tiny water droplet."

"It’s like a capacity meter, which can detect minute pressure changes — much like the sensitivity of a lotus leaf to the extremely light touch of a tiny water droplet."

"It’s like a capacity meter, which can detect minute pressure changes — much like the sensitivity of a lotus leaf to the extremely light touch of a tiny water droplet."

Like the lotus leaf, eAir’s ‘air spring’ design contains a trapped layer of air, forming an air-liquid interface upon contact with the sensor’s liquid. As external pressure increases, this air layer compresses. The near-friction-free microstructures allow the interface to glide along these surfaces, triggering changes in electrical signals that accurately reflect the applied pressure.

“It’s like a capacity meter, which can detect minute pressure changes — much like the sensitivity of a lotus leaf to the extremely light touch of a tiny water droplet,” adds Assoc Prof Tee.

See the technology in action here.

A step-change in the operating theatre

eAir is capable of operating in turbulent liquids, as well as in in vivo biological environments, such as those encountered in laparoscopic procedures. The team has demonstrated its practical use in the in vivo monitoring of intracranial pressure in a rat model, with performance matching that of commercial sensors.

"Our sensor can also be readily integrated with tools that require tactile feedback, such as laparoscopic graspers, which could improve safety and precision in surgical procedures,” says Assoc Prof Tee.

The team envisions the eAir platform evolving into devices with simple, low-cost preparation processes. “Leveraging other solid or quasi-liquid super-slippery surfaces within the microstructures could lead to high-performance eAir sensors that are exceptionally stable,” adds Assoc Prof Tee. “We anticipate more use cases as we test these new approaches for long-term use — watch this space!”

Read More

View Our Publications ▏Back to Forging New Frontiers - July 2024 Issue

If you are interested to connect with us, email us at cdenews@nus.edu.sg