Collaborative research in design – the CALIPSO collaboration

Follow CDE

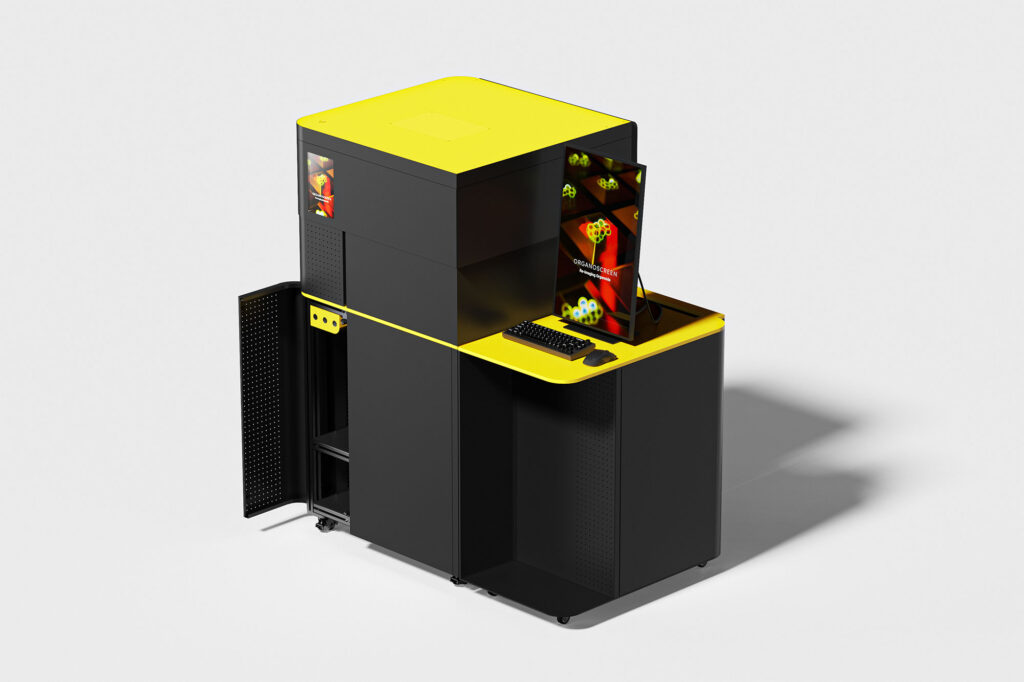

Design elements developed by the Design Incubation Centre converged into the fabrication and successful launch of a working prototype of an innovative advancement in microscopy

The NUS Mechanobiology Institute (MBI) and the French National Centre for Scientific Research (CNRS) located at CREATE embarked on a three-year research programme to develop a new generation of high-content screening platform for simultaneous 3D live imaging of more than 1,000 organoids – miniaturised and simplified versions of an organ produced in vitro.

The project CALIPSO (Computer Assisted Live Imaging for Predictive Screening of Organoids) is an innovative advancement in microscopy leveraging deep learning techniques to enhance and simplify the process of studying and quantifying the morphology of organoids in real-time 3D.

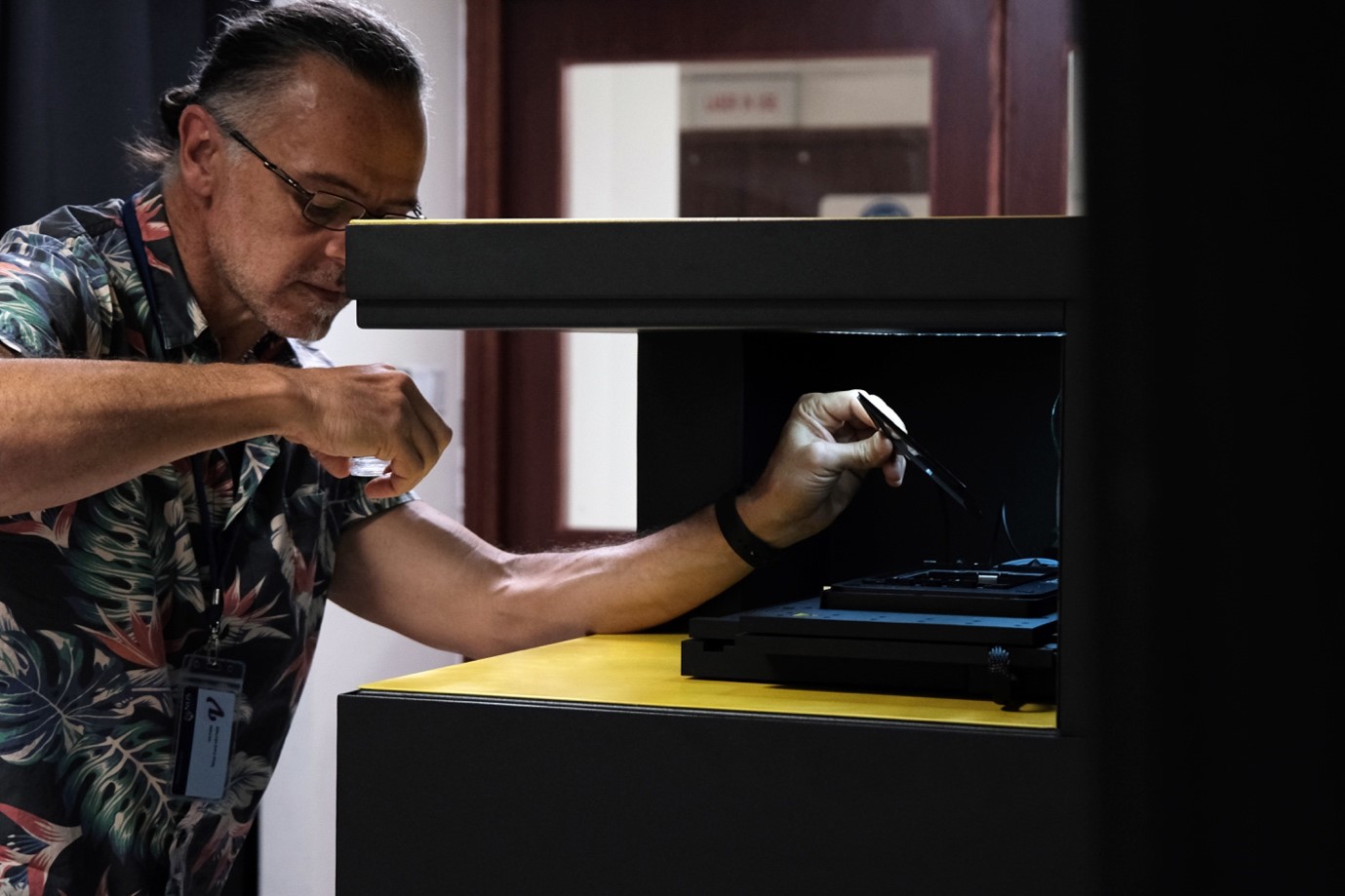

By leveraging the patents of microfabricated chips and soSPIM (Single Objective Selective Plane Illumination Microscopy) technology developed by MBI and CNRS, the College of Design and Engineering's Design Incubation Centre (DIC) embarked on a journey to conceptualise an ideal machine, prioritising ergonomics and user experience. The objective was to address archaic practices associated with out-of-reach optical and electronic components, which, upon initial field observations, were found to generate visual confusion and ergonomic challenges.

The new design offers considerable advantages, providing researchers with enhanced freedom of movement from various angles while working with the incubator. The L-shaped opening allows easier access to the stage chamber, facilitating smoother and more precise placement of petri dishes and other experimental elements.

Moreover, the automated sliding door mechanism ensures that unwanted movements are minimised during the experiment. When the door is closed, it guarantees a complete blackout, maintaining the required experimental conditions without interference from external light sources. This feature contributes to the accuracy and reliability of the research outcomes, as the experiments are conducted in a controlled and undisturbed environment.

The machine was meticulously designed to streamline tasks, establish a clear visual hierarchy of functions, and enhance manipulations. The goal was to enable users to focus more effectively on image acquisition steps, eliminating challenges associated with outdated methodologies.

Multiple design elements were implemented:

- Sliding door down - Safety in motion: Automated to prevent unintended movements

- Sliding door up - Darkness on demand: designed for complete blackout

- L-shaped opening - Freedom of movement: Entry from various angles

- Remote control - Seamless integration: magnetic convenience, easy retrieval

- Main switch - Control in disguise: Concealed buttons for intuitive usability

- Screen - Real-time visibility: instant access to key project information

- Holes on door - Optimal ventilation: perforated for internal cooling

- Cable management - Out of sight: single access for cable-free setup

Although seemingly simple and intuitive, these design elements required an in-depth understanding of the technologies applied in CALIPSO, and expertise in fabrication, including the exploration of new materials to achieve the intended design result.

Combined with the technological innovations from MBI and CNRS, these design elements converged into the fabrication and successful launch of a working prototype, fully functional in all aspects. Already integrated within the MBI microscopy platform, Singapore and French scientists will test the machine for at least one year. This implementation will help to identify the possible improvements from the perspective of an optimised second version. Further technical work is ongoing to reduce the size of the system, making it more accessible to labs and improving its commercial viability. Collaborators will consider licensing the patents or creating a start-up around the product.

The collaboration also enabled young designers (alumni from the College's Division of Industrial Design) under the mentorship of DIC experts to confront a project that had scale and complexity rarely approached at such a level of realisation, allowing them to acquire new knowledge and skills valuable for their future professional development.

Koh Bei Ning, an Industrial Design alumnus who had participated in the latest stage of the project, shared that “Being a part of the CALIPSO project allowed me to experience the way different disciplines come together for innovation and the role we each play for the concept to come to life. It was a valuable opportunity for me to apply the skills and principles taught in DID and understand how a product’s usability is crucial to help technology serve its users to the fullest.”

Anticipating further value-add from the experience, Project Director Christophe Gaubert stated that “Design was brought to its rightful place early in the process. It allowed a genuine dialogue between the scientific and the design teams, leading to a shared definition of the issues, developing the brief together, agreeing on the vision and ambition of the project, and co-designing an innovative product, innovative because it was thought of in the right way since the very beginning.”

For more information on CALLIPSO’s design: https://designincubation.sg/project/calipso

Project Director: Christophe Gaubert

Project Manager: Poh Yun Ru

Designers: Tommy Cheong, Koh Bei Ning, Yuta Nakayama, Tan Wei Jing, Cynthia Chan, Shawn Ng, Anh Nguyen, Willie Tay

About DIC:

Design Incubation Centre (DIC) is part of the Division of Industrial Design (DID), College of Design and Engineering (CDE) at National University of Singapore (NUS). With the mission to incubate ideas, projects and talents, DIC takes part in the emergence of a new generation of Singapore designers. By also developing research, probe projects and educational programmes, DIC contributes to identifying new industrial, social, and cultural territories where design will gravitate and grow in the coming decades. Through academic and professional collaborations with other NUS faculties, government agencies and private industry, DIC also promotes the role of design in those organisations as a keystone of human-centred innovation.

Related

Christophe Gaubert ▏Associate Professor (Practice), Division of Industrial Design ▏ Director, Design Incubation Centre

Related Departments

If you are interested to connect with us, email us at cdenews@nus.edu.sg