An innovative medical pressure sensor, inspired by the way water droplets roll off a lotus leaf, has been unveiled by researchers at CDE.

Named ‘eAir’, the aero-elastic sensor promises increased precision and reliability across a wide range of medical applications, particularly minimally-invasive surgeries and procedures using implantable sensors.

In laparoscopic surgery, for example, the sensor could offer transformative advances by enabling tactile feedback for surgeons, allowing more precise manipulation of patient tissues.

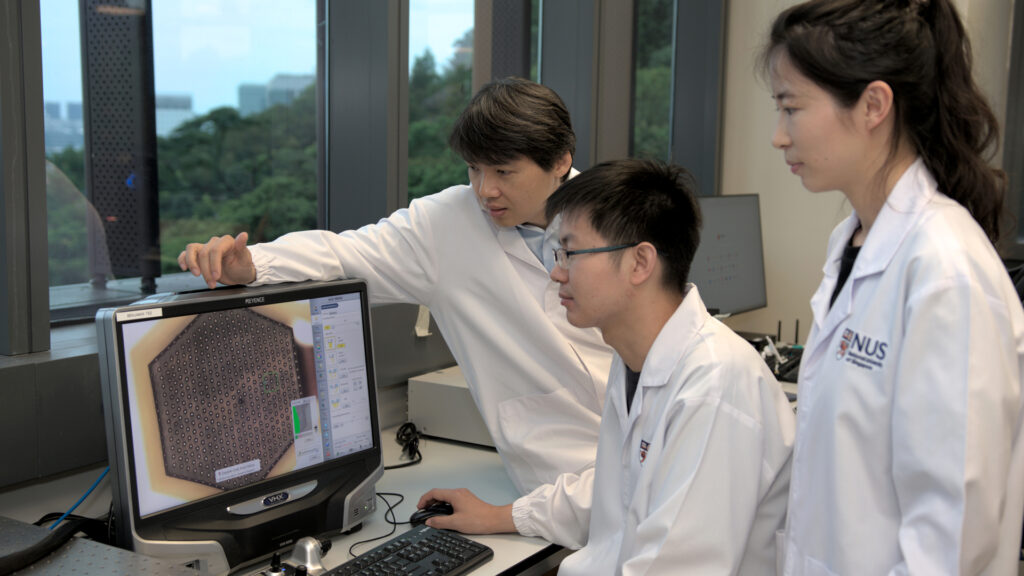

The research team behind the breakthrough was led by Associate Professor Benjamin Tee (Materials Science and Engineering and NUS Institute for Health Innovation & Technology), with their findings published in the scientific journal Nature Materials.

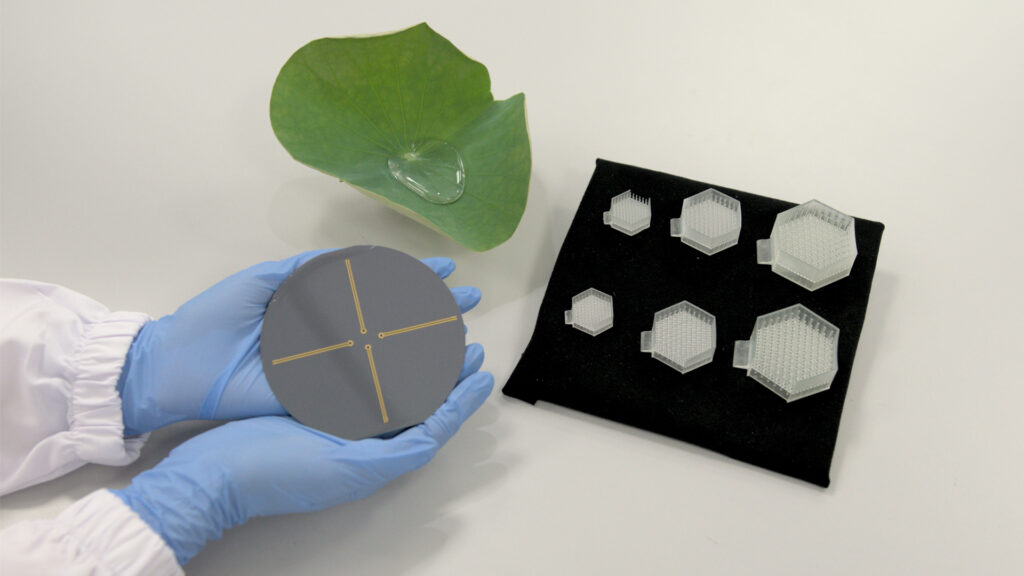

In designing eAir, the team drew inspiration from a nature phenomenon known as the ‘lotus leaf effect’ —where water droplets effortlessly roll off the plant’s surface, due to the leaf’s minuscule, water-repelling structures.

“The sensor, akin to a miniature ‘capacity meter’, can detect minute pressure changes — mirroring the sensitivity of a lotus leaf to the extremely light touch of a water droplet,” said Assoc Prof Tee.

‘Air spring’ design

The eAir sensor employs an innovative ‘air spring’ design that reimagines the mechanics behind a lotus leaf’s water-repelling capabilities as a powerful and highly accurate pressure-sensing tool.

The researchers say eAir represents a major step forward from conventional pressure sensors which are typically made from stiff, mechanically inflexible materials and frequently struggle with accuracy or delivering consistent readings.

For example, conventional sensors often return varying results when the same pressure is applied repeatedly and can overlook subtle changes in pressure — all of which can lead to significant errors.

Assoc Prof Tee says the potential applications of this nature-inspired technology are wide-ranging. For instance, in laparoscopic surgeries, where precise tactile feedback is indispensable, incorporating eAir sensors could lead to safer surgical procedures, ultimately enhancing patient recovery and prognosis.

“Conducting surgeries with graspers presents unique challenges,” he said. “Precise control and accurate perception of the forces applied are critical, but traditional tools can sometimes fall short, making surgeons rely heavily on experience and even intuition. The introduction of soft and readily integrable eAir sensors, however, could be a game-changer.”

Revolutionary potential

Dr Kaan Hung Leng, Consultant in the Department of General Surgery at the National University Hospital who was not involved in the research, said introducing the eAir sensor technology could have a transformative impact on the field of minimally-invasive surgery, delivering improved surgical and patient outcomes.

“When surgeons perform minimally-invasive surgery such as laparoscopic or robotic surgery, we can control the jaws of the graspers, but we are unable to feel what the end-effectors are grasping. Hence, surgeons have to rely on our sense of sight and years of experience to make a judgement call about critical information that our sense of touch could otherwise provide,” said Dr Kaan, who is also with Ng Teng Fong General Hospital and NUS Yong Loo Lin School of Medicine.

“The haptic or tactile feedback provided by smart pressure sensors has the potential to revolutionise the field of minimally-invasive surgery. For example, information about whether a tissue that is being grasped is hard, firm or soft provides an additional and important source of information to aid surgeons in making prudent decisions during surgery.”

In another promising application, the research team says eAir presents an opportunity to improve the process of monitoring intracranial pressure — the pressure within the skull that can influence brain health and a key health metric for individuals with neurological conditions.

By offering a minimally invasive solution, the technology could transform patient experiences in the management of brain-related conditions, ranging from severe headaches to potential brain damage.

Going forward, the research team is laying the groundwork for collaborations with key players in the medical field and aim to translate the technology for real-world applications.

“We want to further refine the eAir sensor to enhance its performance by exploring various new materials and microstructural designs,” said Assoc Prof Tee.

* Article from College of Design and Engineering, NUS news