Final year students from the Industrial Systems Engineering & Management (ISEM) programme teams presented practical design solutions developed over nine months at the Systems Design Project (SDP) Industry Showcase and Poster Exhibition 2025, held on 11 April 2025. Supported by industry partners, the exhibition is a platform for students to showcase their capabilities in tackling real-world challenges.

One student group focused on improving business operations by creating an automated and integrated web application. Another group worked on reducing the travel time of Autonomous Mobile Robots (AMRs) in Micron’s warehouse to enhance order fulfilment.

“The Systems Design Project (SDP) allowed us to apply our Industrial and Systems Engineering knowledge in a meaningful, real-world context. One of our team’s biggest takeaways was learning how technical models can drive meaningful impact,” shared Tai Chen Jie, a Year 4 Industrial and Systems Engineering (ISE) student.

Labour Ward Optimisation

This project team addressed ward congestion, hospital bed shortages, and resource constraints in hospitals' delivery suites. They sought to optimise resource allocation, streamline patient flow, and improve efficiency in the KKH Delivery Suite. The goal was to reduce waiting time, alleviate overcrowding, and enhance patient care.

A digital twin was developed based on historical data to simulate and analyse various "what-if" scenarios, such as staff shortages, bed closures, or unexpected surges in patient arrivals.

To ensure its feasibility and effectiveness, the team demonstrated the capabilities of their simulation model to doctors, nurses, and operational staff.

Ms Pang Nguk Lan, Director of Special Projects (CMB Office) at KKH, was impressed with the team's solutions and praised them for taking pride in their work. She emphasised, "Nothing is impossible if you are willing to share and develop new technology to help the community."

The team reflected how their work on the project highlighted the importance of systems thinking in a real-world healthcare setting. Tai Chen Jie noted, “We are now more inclined to explore careers in healthcare operations, analytics, and process improvement, where we can continue to design solutions that make a difference in people’s lives.”

Team members: Daine Seah Gin Hsien, Jerrick Chew Jun Ying, Nicholas Lee Wei Boon and Tai Chen Jie

Department Supervisor: Associate Professor He Shuangchi

Industrial Supervisors: Dr Samantha Rachel Yeo and from KK Women's and Children's Hospital

Project Advisor and Facilitators: Ms Pang Nguk Lan, Mr Bernard Wong and Ms Jeslyn Neo from KK Women's and Children's Hospital

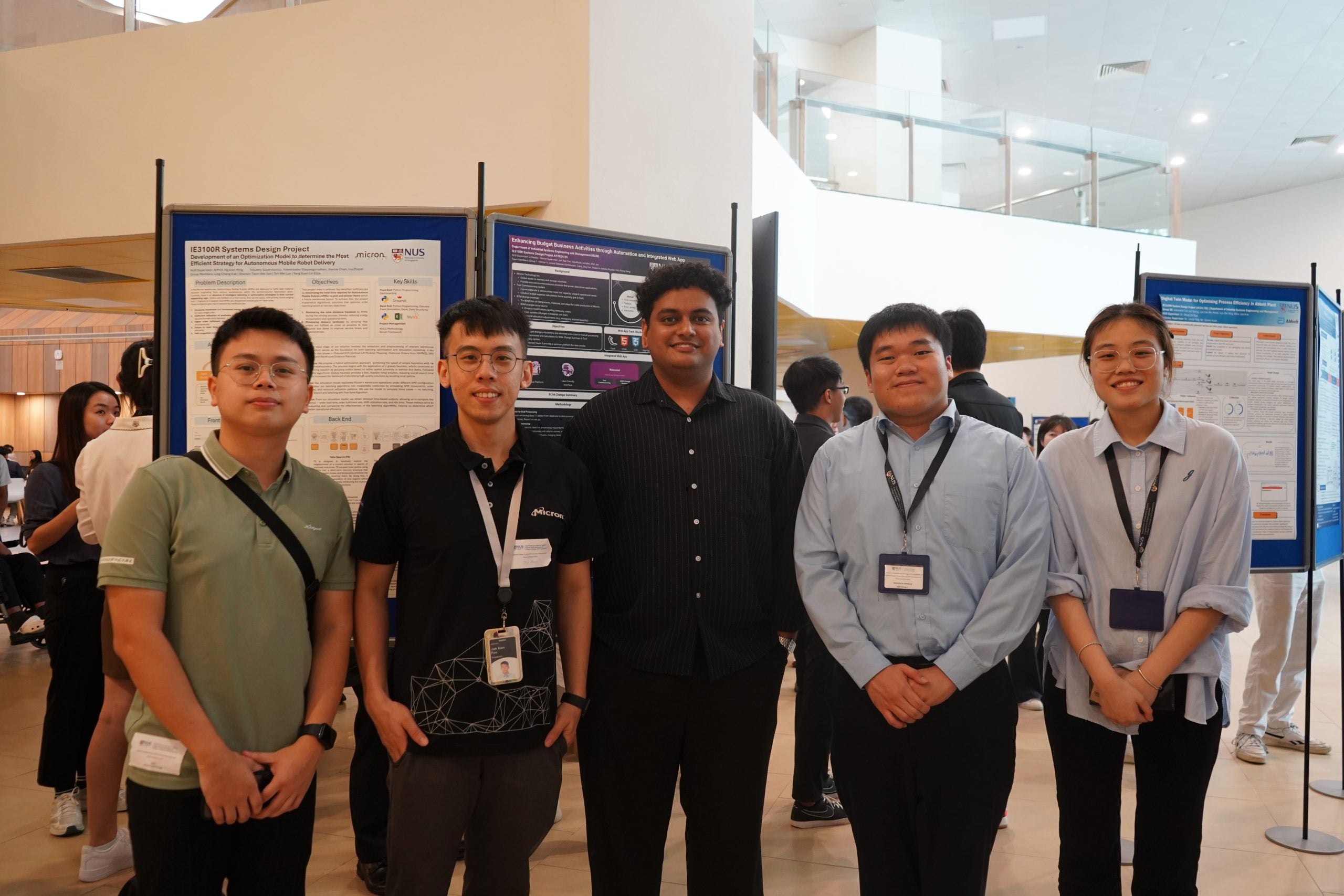

Enhancing Budget Business Activities through Automation and Integrated Web App

The team developed an integrated web app to automate and improve Micron Technology's business activities, specifically on tool commissioning and the Bill of Materials (BOM) change summary. The existing manual process took up too much time and occasionally led to cross-team communication delays.

To address these challenges, the team created a user-friendly web app that standardises processes, reduces errors, and improves reporting accuracy. The app integrates tool commissioning and BOM change summary activities, minimising data loss risk.

By automating budget calculations, the web app significantly reduced the need for manual labour and accelerated workflow, making operations approximately 1,800 times faster. Automation was implemented using Python scripts, which reduced the time required for calculations from around 85 hours per quarter to less than 10 minutes. In addition to decreasing the hours needed, this automation eliminated manual errors, improved team communication, and centralised tool commissioning files in a shared drive with consistent formatting.

One of their industry supervisors from Micron Technology, Mr Jun Xian Foo, noted, “The students have made significant contributions to enhancing the efficiency and accuracy of budget business activities through innovative automation solutions and the development of an integrated web application, and I personally value their contributions and look forward to more collaborative opportunities with the team!”

Team Members: Anand Sreeram Karthikeyan, Liang Jing Yun, Roderick Antolis and Roydan Peh Zhong Heng

Department Supervisor: Dr Li Xiaobo

Industry Supervisors: Mr Jun Xian Foo, Ms Nurulhuda Jumahri and Mr Aldo Jeo from Micron Technology Inc

Development of an Optimisation Model to Determine the Most Efficient Strategy for Autonomous Mobile Robot Delivery

The team developed an optimisation model to determine the most efficient Autonomous Mobile Robot (AMR) delivery route. Using algorithms like Tree Seed and Tabu Search within a Rolling Horizon framework, the approach ensured that the planned route for the AMR is regularly updated as new orders come in or conditions change. This allowed the robots to navigate the warehouse more efficiently, saving time and facilitating faster order completion. As a result, the team reduced AMR travel time and enhanced order fulfilment. This advancement increases warehouse efficiency and supports more intelligent, data-driven logistics.

Team members: Ling Cheng Kiat, Sherwin Tieon Wei Jian, Toh Wei Lun and Yang Xuan Lin Eliza

Department Supervisor: Associate Professor Ng Kien Ming

Industry Supervisors: Mr Yokeshbabu Vijayaragunathan, Ms Joanne Chan and Ms Liu Zhepei from Micron Technology Inc

Development of a Dynamic Simulation Platform for Future Hospital Planning

This project team developed a system model tool for decision-makers at SingHealth to forecast future hospital capacity needs. This tool included data visualisation and adjustable parameters to help decision-makers explore various scenarios, enabling stakeholders to make informed decisions regarding the capacity of future healthcare systems.

Team Members: Chen Chwen Huey, Jon Tan Ee Xin, Lu Yu Ting and Zhang Guoyun

Department Advisor: Dr Wang Zhiguo

Industrial Supervisors: Dr Sean Lam Shao Wei and Dr Ashish Kumar from SingHealth