Chemical and Biomolecular Engineering

A new recipe for modelling chemical processes

Follow CDE

PDF Download

A machine-learning framework helps engineers build models for new chemical processes by combining knowledge from existing ones.

Master chefs and chemical engineers have more in common than one might expect. Both work based on recipes — some passed down, some improvised along the way — and both are in the business of mixing ingredients under certain conditions to produce consistent results.

Cooking, like chemical engineering, involves a heap of experimentation. But when it comes to inventing something new, even chefs don’t start from scratch.

They draw on flavours and techniques from other dishes. They borrow, tweak, adapt. Chemical engineers, too, are doing the same — with the help of machine learning.

In a study published in Chemical Engineering Science, Assistant Professor Wu Zhe from the Department of Chemical and Biomolecular Engineering, College of Design and Engineering, National University of Singapore, introduced a method that allows engineers to build predictive models for complex chemical systems using knowledge from multiple existing ones.

The team’s method is grounded in “multi-source transfer learning”, a machine-learning technique where models trained on one or more existing processes are adapted to help understand a new but related process. But things get complicated when more than one source needs to be managed simultaneously, particularly when those sources vary in how helpful (or not) they might be.

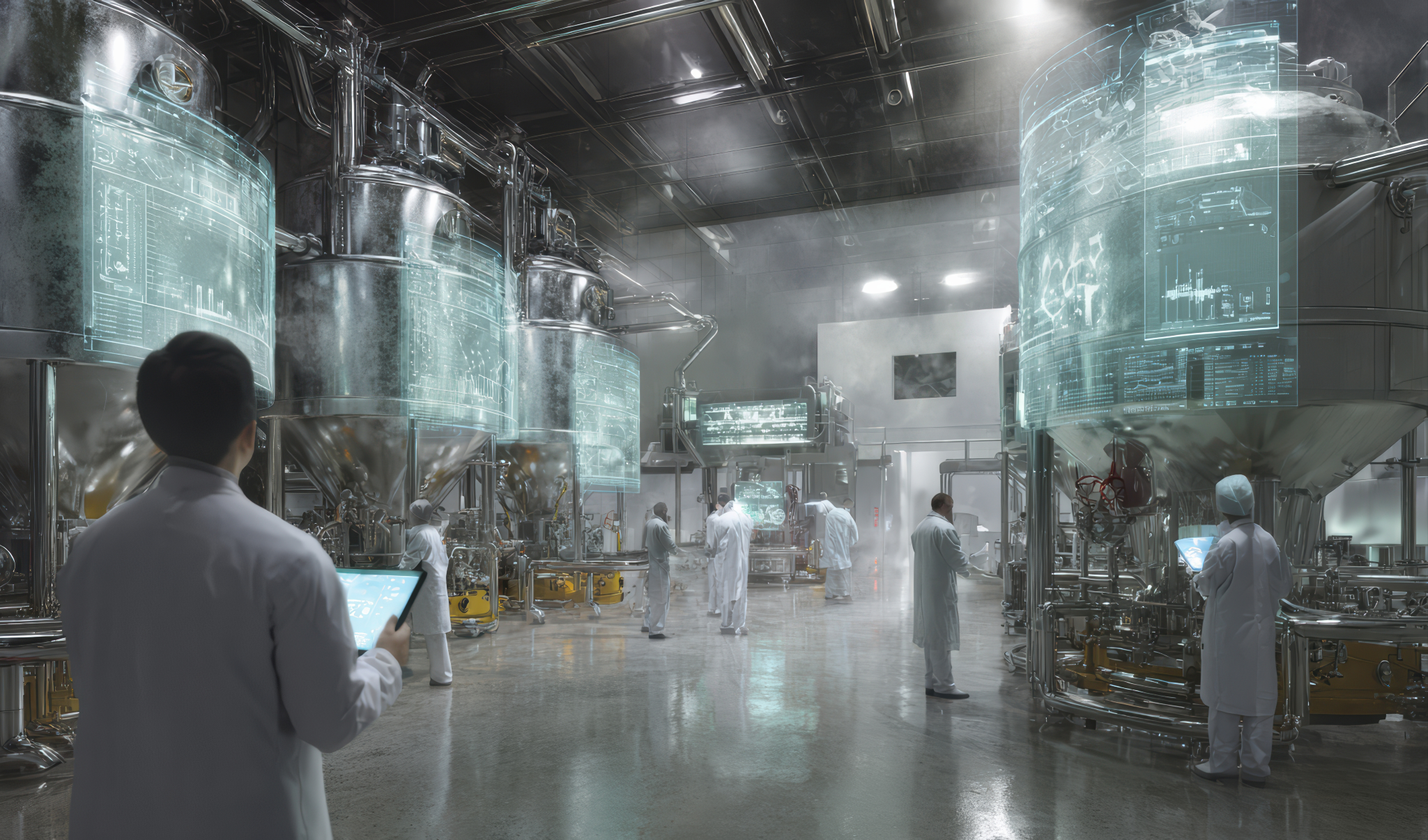

Assistant Professor Wu Zhe and his team introduced a machine-learning framework that builds predictive models for new chemical processes by combining knowledge from existing ones.

Such challenges compound in the face of chemical manufacturing. Whether producing active pharmaceutical ingredients or designing new catalysts, every process has its own kinks as conditions and dynamics wax and wane. Some systems are easier to model because there’s plenty of historical data. Meanwhile, some are newer or less accessible, creating a data void. Yet all systems require accurate models to predict how they will behave under changing conditions.

Transfer learning offers an effective workaround. “Instead of building and training a model entirely from the ground up, which is often costly and data hungry, our approach figures out which ‘past recipes’ are most relevant, and what is the best way to combine them to suit the new process,” says Asst Prof Wu. “However, knowing which source to trust, and how much to rely on it, is another challenge.”

To build that trust Asst Prof Wu’s team developed an optimisation-based framework that helps select and weight the best combinations of source models, using a mathematical measure called the generalisation error bound. It helps estimate how well a model adapted from one process will perform on another.

This mathematical backbone helps engineers avert the pitfall of blindly reusing data from mismatched systems. “The framework evaluates how similar the input conditions are, as well as how the system’s dynamics, or the ‘outputs’, behave,” Asst Prof Wu explains. “This gives us a more robust way to choose our sources.”

“The framework evaluates how similar the input conditions are, as well as how the system’s dynamics, or the ‘outputs’, behave.”

“The framework evaluates how similar the input conditions are, as well as how the system’s dynamics, or the ‘outputs’, behave.”

“For instance, say you’re trying to model a new process to produce a pharmaceutical compound but only have limited data. Instead of starting from scratch, the framework draws from other existing processes, perhaps one that makes a similar drug, another with overlapping temperature conditions and a third that’s only vaguely related. It then weighs how useful each one is, combining the most relevant parts to build an accurate model for the new process,” adds Asst Prof Wu.

The team’s framework builds on their prior work in transfer learning, including a 2023 paper in the AlChE Journal that introduced a method for adapting models from a single source to a target process. “This current study extends our past work to multiple sources, each with varying degrees of relevance, allowing a more nuanced and flexible approach to model building.”

“The framework evaluates how similar the input conditions are, as well as how the system’s dynamics, or the ‘outputs’, behave.”

“For instance, say you’re trying to model a new process to produce a pharmaceutical compound but only have limited data. Instead of starting from scratch, the framework draws from other existing processes, perhaps one that makes a similar drug, another with overlapping temperature conditions and a third that’s only vaguely related. It then weighs how useful each one is, combining the most relevant parts to build an accurate model for the new process,” adds Asst Prof Wu.

The team’s framework builds on their prior work in transfer learning, including a 2023 paper in the AlChE Journal that introduced a method for adapting models from a single source to a target process. “This current study extends our past work to multiple sources, each with varying degrees of relevance, allowing a more nuanced and flexible approach to model building.”

Cooking up efficient chemical processes

Conducted as part of the Pharma Innovation Programme Singapore (PIPS), a multi-institutional initiative involving industry collaborators such as GSK, Pfizer, MSD and Syngenta, the team’s work addresses the need for efficient, scalable modelling tools in pharmaceutical and chemical manufacturing.

In one case study, the team applied their approach to a simulation of a continuous stirred tank reactor, a standard equipment in chemical plants. By drawing from a combination of previously modelled reactors — each slightly different in parameters or operating ranges — they demonstrated that their multi-source approach resulted in better predictive accuracy than using any single source alone. Excitingly, even when the data from the target process was limited, the method still produced models robust enough to support downstream control systems.

“In chemical plants, these models feed into complex control systems that keep tabs on a plethora of operating conditions, from pressure to temperature to flow rates to feed ratio — all in real time,” adds Asst Prof Wu. “A robust, accurate model ensures safety, boosts efficiency and increases economic value.”

The team is now exploring how the method could be applied to photochemical reactors, which are traditionally difficult to model due to their complex dynamics and limited kinetic data. In parallel, they are planning collaborations with biopharmaceutical companies to support the scale-up of bioreactor systems, where nonlinear dynamics and data scarcity similarly pose hurdles.

“We aim to show how transfer learning can bridge knowledge gaps across diverse chemical processes, accelerating innovation even when data or theory is incomplete,” says Asst Prof Wu.

Read More

View Our Publications ▏Back to Forging New Frontiers - August 2025 Issue

If you are interested to connect with us, email us at cdenews@nus.edu.sg