-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures

- Centre for Hazards Research

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research

- Centre for Water Research

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

Low-carbon Construction Materials Incorporating Solid Waste

This project aims to deliver a low-carbon class of building materials that accommodate solid wastes, exhibit high durability and cause low environmental impact. Conventional concrete is often criticised for its high carbon footprint and low resilience against severe conditions. This project will develop sustainable materials by incorporating waste glass as cement replacement. Its performance, such as strength and durability, will be investigated. The outcomes are expected to help increase sustainability, durability and resilience of materials in our national building construction industry.

Concrete is the most widely used man-made material in the world. It is second only to water as the most-consumed resource on the planet. Cement, as the most important binding agency in concrete, is the source of about 8% of the world’s carbon dioxide emission. Previous studies have demonstrated the viability of using waste glass to replace cement to make concrete more sustainable and higher performance. In Singapore, 75, 000 tonnes of glass were generated in the year of 2019. However, only 14% of the total generated waste glass was recycled while 86% of the waste glass was sent to landfill. For the recycled glass, they were shipped overseas for upcycling. This project aims to utilize the locally generated waste glass to substitute cement in the production of non-structural concrete. This can not only reduce the embodied carbon in the concrete materials but also reduce the amount of solid waste disposed to landfill.

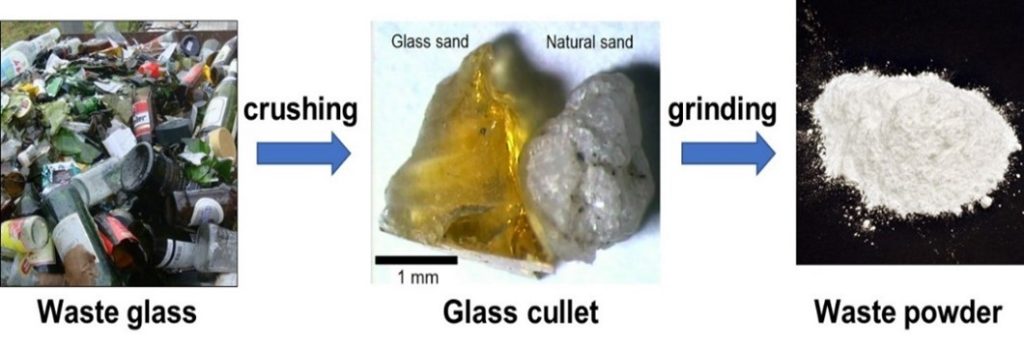

The project conducts a cost-effective treatment to physically crush and grind the waste glass into powders (see Figure 1). The powders will be used as cement substitute in concrete production. The optimum range of glass powder fineness and replacement level will be determined based on the concrete performance. The life-cycle environmental impact will also be evaluated from the concrete durability performance.

Figure 1. Processing of waste glass to glass powder

Under the supervision of Dr. Du Hongjian, a team of NUS undergraduate students have won the 1st Place Prize in the Innovation in Public Transportation Competition 2021, organized by Asia-Pacific Economic Cooperation (APEC). The team was awarded for the entry titled Sustainable Concrete Made from Solid Waste Glass.

More information can be found: http://www.railmetrochina.com/circ/en/competition.

For more details, please contact:

Dr Du Hongjian

Email: ceedhj@nus.edu.sg