Effluents from pharmaceutical industries are generally characterised by high COD and TDS and contain copious amounts of refractory organic solvents that contribute significantly to the overall organic concentrations. The project aims to provide a comprehensive solution for treating organic wastewater from the pharmaceutical and fine chemical industries. Specifically, it is to develop a cost-effective process for concentrating organic ingredients in wastewater such that energy and water can be recovered and recycled.

Part of the project is to treat the diluted organic wastewater after extraction processes to meet trade effluent discharge. Treatment approaches like biological treatment, membrane processes, and advanced oxidation processes have been previously employed for treating such pharmaceutical facilities’ effluent. Still, they are laced with challenges and limitations—this positions adsorption as a promising and robust treatment for pharmaceutical wastewater. However, after they are exhausted, adsorbents are incinerated or disposed of in landfills. This entails both environmental and economic setbacks. To better position adsorption as a more environmentally friendly and economical treatment, regeneration of adsorbents to restore adsorptive capacity is critical.

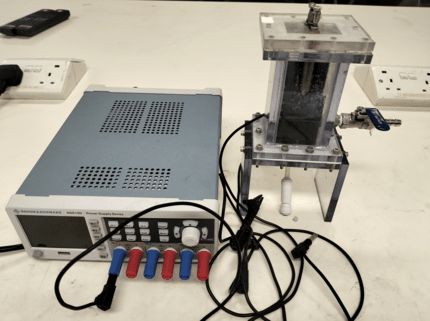

As pharmaceutical wastewaters are often associated with high salinity and conductivity, these are propelling reasons for using electrochemical advanced oxidation processes as a part of the solution for the project. Therefore, engaging in electrochemical regeneration of activated adsorbents has been recommended. It is also accompanied by other benefits like minimal employment of chemicals with the in-situ generation of free radicals through electrochemistry, making it more environmentally friendly. Hence, a process of 3D/GAC/O3 was proposed to treat pharmaceutical wastewaters. 3D/GAC/O3 can achieve synergistic production of OH radicals for pollutant degradation in pharmaceutical wastewater through mechanisms like O3-electrolysis, catalytic ozonation and peroxone reaction. 3D/GAC/O3 can enhance mineralisation and improves the overall biodegradability and toxicity of the pharmaceutical wastewater, potentially paving the way for adopting this process as an additional pre-treatment to degrade before an inexpensive biological process.

3D/GAC/O3 displayed an enhanced organic abatement. The apparent rate constant of 3D/GAC/O3 in terms of TOC was approximately 81% greater than the sum of the rate constants for ozonation and electro-oxidation. As oxidative processes were introduced, biodegradability was improved, reaching 0.86 for BOD5/COD and 12.4% acute toxicity inhibition was achieved after being treated with the 3D/GAC/O3 process. The enhanced biodegradability (BOD5/COD) and decrease in acute toxicity are attributable to the overall breakdown of these recalcitrant and toxic N-containing solvents commonly reported. More importantly, 3D/GAC/O3 does not considerably increase the energy required for TOC and COD removal when compared to other methods while significantly improve the pace of organic abatement.

For more details, please contact:

Prof Hu Jiangyong

Email: ceehujy@nus.edu.sg