Water disinfection is essential to our daily lives and industries, especially aquaculture. Insufficient water disinfection may lead to disease outbreak and cause tremendous economic loss. Every year global aquaculture loss due to disease outbreak is estimated to be 13 billion Singapore dollar.

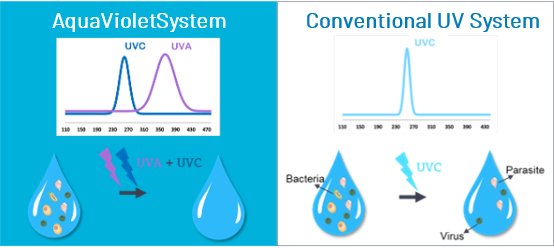

As a result, UV is widely adopted in aquaculture for water disinfection. However, there have been some constraints for the mercury lamp-based UV systems which are dominant in the market. These constraints include 1) the light emitted by these systems have a narrow killing spectrum. It is not effective against many types of microbes, such as bacteria, virus and parasites. 2) mercury UV systems have a short life span. UV lamps need to be replaced every 6 to 12 months. And 3) current mercury-based system requires very tedious maintenance, customers need to handle the fragile lamps and sleeves during lamp replacement and cleaning.

Figure 6. Comparison between AquaViolet novel UV-LED technology and conventional mercury UV disinfection systems

To address these constraints, we developed a patented disinfection technology emits UV light in both UVA and UVC range so to kill more types of microbes. As compared to the existing mercury UV products, our device will be able to 1) kill a broader range of microbes, 2) have longer life span and 3) be easier to install and maintain.

During this project, a prototype with the treatment capacity of 0.1 m3/h was developed and tested in a small-scale recirculating aquaculture system for shrimp farming. The whole test last for 4 months. The first two months mainly focused on the stability of system and comparison with commercial mercury UV product. It was obvious that the disinfection efficiency for the mercury UV kept decreasing while that for the UVA-UVC LED system maintained stable. In the first week, the disinfection efficiency of the mercury UV system (average log removal = 1.93 logs) and the UVA-UVC LED system (average log removal = 1.77 logs) was similar (p > 0.05). However, the disinfection efficiency of mercury UV system was dropped rapidly from 2.26 logs to 0.57 logs within three weeks, while the prototype of the UVA-UVC LED system delivered a stable disinfection efficiency (around 2.0-2.5 logs, p > 0.05) during the whole 6-week testing period. This result suggests that the UVA-UVC LED system could be more stable comparing with the mercury UV system, which will help the farmers to prevent more losses due to disease outbreak if installed in aquaculture farms.

Figure 7. Prototype of AquaViolet Novel UV-LED disinfection technology with treatment capacity of 0.1m3/h

With the data generated in the 4-month pilot tests, the second prototype was then developed. The main improvement of this prototype was the increase of treatment capacity. This prototype is able to deal with a flow rate up to 1.0 m3/h, which will be sufficient for pilot trials with commercial fish/shrimp farming companies. The project team has received 4 letters of intent from local aquaculture companies for pilot trials and we plan to use this prototype to test with one of the leading local aquaculture companies.

Figure 8. Prototype and installation of the prototype on the site of potential customers

For more details, please contact:

Prof Hu Jiangyong

Email: ceehujy@nus.edu.sg