-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures (CAMS)

- Centre for Hazards Research (CHR)

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research (CTR)

- Centre for Water Research (CWR)

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience (CES)

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

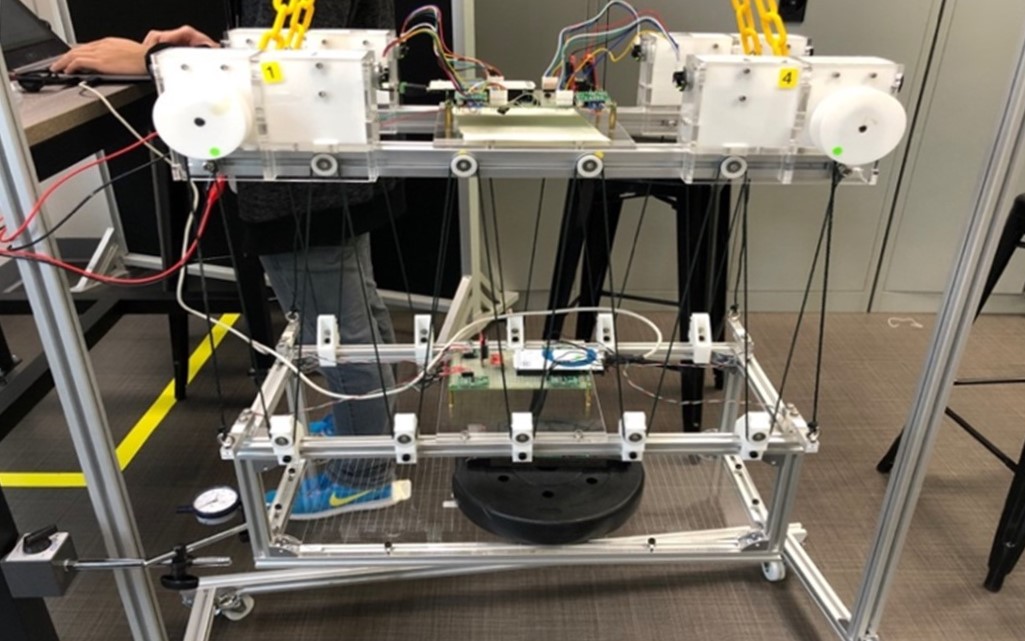

Intelligent Lifting Frame for PPVC and Precast Construction

The project specifically designs a lifting frame that can allow for the efficient installation of modular units in prefabricated prefinished volumetric construction (PPVC). There are two objectives to this lifting frame. It has an anti-sway control so that the orientation of the modular units can be controlled. In this way, the payload can reach the planned destination in a minimum time with less sway. The project also addresses issues related to alignment and adjustment just before installation as findings show that the bulk of the time is taken when trying to fit the unit into its final placement. This is achieved through autoleveling and fine lateral adjustments of the modular frame using the lifting frame.

In order to move the PPVC more effectively and accurately, we propose to install an intelligent frame that is able to move the PPVC.

In this project, a full-scale prototype of an intelligent frame that comprises the self-leveling, anti-sway, and lateral adjustment systems. Apart from ensuring that a PPVC module is level during the hoisting process, the self-balancing system will also keep the module level as it is lowered into position. With closed loop control algorithms, it will respond to additional offsets to the centre-of-gravity of the lifting frame and/or the module that are caused by adjustments for anti-sway and lateral positioning.

A table prototype is being built to define the design of the anti-sway, self-leveling and lateral adjustment mechanisms. This will then be scaled to a 1-ton prototype and eventually to the full scale prototype with a payload of 30 tons.

For more details, please contact:

Prof Chua Kim Huat, David

Email: ceedavid@nus.edu.sg