-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures (CAMS)

- Centre for Hazards Research (CHR)

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research (CTR)

- Centre for Water Research (CWR)

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience (CES)

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

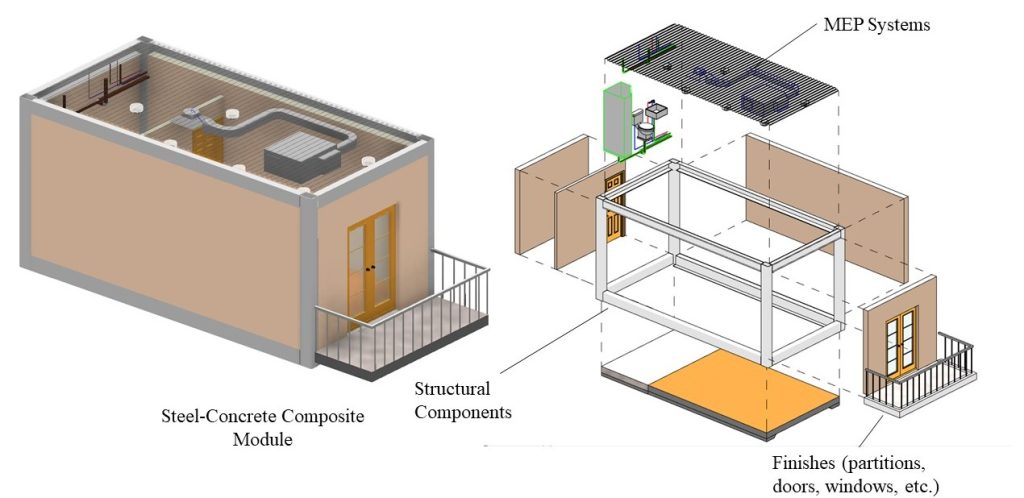

Lightweight High-Strength Steel-Concrete Composite Modular Buildings with Fast Track Connections

Prefabricated Prefinished Volumetric Construction (PPVC) is a prefabricated modular technology which promotes off-site manufacturing of modules and on-site assembly by improving the construction efficiency, safety, and productivity. A novel lightweight steel-concrete composite system has been developed to reduce the weight of the module without compromising the strength and stiffness.

- A novel lightweight slim floor system is proposed to reduce the floor-to-floor depth and ensure the integration of building services within the structural zone. The slim floor system utilizes lightweight steel fiber reinforced concrete without conventional reinforcements, which can increase productivity and reduce the self-weight of module. The proposed slim floor system can save up to 30% the overall cost of the module production.

- High strength concrete is used as an infill material for tubular columns to maintain the same column size to avoid complex joining details involving modules with different column sizes. The high strength concrete developed by NUS utilizes industrial waste, fly ash, to replace cement to promote the more sustainable development of construction. Cement production is a major source of carbon dioxide emissions. Hence, the developed high strength concrete with fly ash can also help to reduce the carbon footprint of modular construction.

- Long-span steel concrete composite modular system is proposed to reduce the number of joints and columns for fast-track construction. A patented grouted sleeve joining technique is developed to ensure fast installation of modules without welding and bolting. The proposed joints can develop sufficient moment and tension resistance to ensure the structural integrity and overall stability of tall modular buildings.

- A BIM platform has been built up based on a shared PPVC Status Database which can be continuously updated. The PPVC Status Database keeps a record of the various stages that a part passes through from casting to its inclusion into a PPVC unit and onto to delivery and installation at the construction location. With suitable software and hardware, productivity metrics can be produced as well as identifying bottle necks in the processes which need management attention.

For more details, please contact:

Prof Liew Jat Yuen Richard

Email: ceeljy@nus.edu.sg