-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures (CAMS)

- Centre for Hazards Research (CHR)

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research (CTR)

- Centre for Water Research (CWR)

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience (CES)

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

Enhancing Offshore System Productivity, Integrity and Survivability in Extreme Environments – WP2: Local Digital Twin

Fatigue or corrosion damage at critical hotspots in offshore and marine structures poses severe threats to the safety of these structures and can lead to substantial financial, ecological or human losses. Accurate prediction of both early stage damage, when the repair cost is low and manageable, and the evolution of the damage, is essential for their sustainable and safe operation. The digital twin, coupled with modelling and sensor data, creates a duplicate of the physical asset in the digital world and allows identification of the critical hotspots and accurate predictions of the damage initiation and evolution under complex loading conditions.

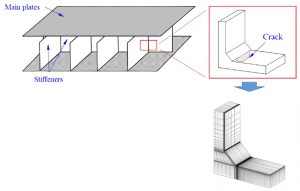

A digital twin for a local detail

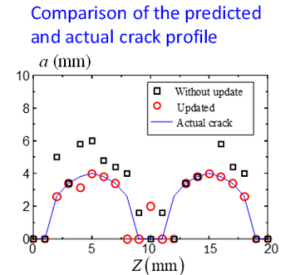

Digital twinning of engineering structures under cyclic actions, e.g. bridges, ships, and offshore platforms, requires a progressive update on the possible crack sizes at critical details. Under cyclic environmental loadings, accurate crack size estimation is essential in evaluating the remaining fatigue life of welded structural components before a repair becomes mandatory. The accurate fatigue assessment depends on the precise fatigue crack initiation and propagation evaluation. This research work proposes an adaptive learning framework to determine and update the crack-front profile at the toe of welded plate joints based on the strain relaxation data. This study determines the crack depth by classifying the nodes in the thickness direction as open nodes on the crack surface and closed nodes on the intact ligament, through a neural network approach (Fig. 1). To update the crack size during the loading history, this research employs the modified bootstrap particle filtering approach (Fig. 2), which entails enhanced adjustment capabilities by imposing additional uncertainty distributions. This approach improves the crack size prediction by absorbing limited measurement data on the strain values or crack sizes (Fig. 3).

|

Fig.1 |

Fig.2 |

Fig.3 |

For more details, please contact:

Assoc Prof Qian Xudong

Email: qianxudong@nus.edu.sg