-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures (CAMS)

- Centre for Hazards Research (CHR)

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research (CTR)

- Centre for Water Research (CWR)

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience (CES)

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

Development of Sustainable Self-Healing Concrete by Use of Recycled Materials

Cracking in concrete is inevitable due to its low tensile strength. The presence of cracks in concrete enables the ingress of water and harmful ions, leading to reduction in the durability and integrity of structural concrete causing corrosion. This is prevalent in the current era of aging structures globally. In order to overcome this, the self-healing mechanism is introduced in concrete, giving the material the ability to repair or seal microcracks as well as recover its mechanical and durability performance by itself without human intervention. The self-healing ability in concrete helps to prolong the lifespan of structural concrete thus reducing its carbon footprint.

The aim of the project is to develop self-healing concrete using sustainable and recycled materials, which are suitable for use in structural and infrastructural applications. Concrete with self-healing ability can be cost effective in terms of labour and maintenance costs, as it is able to provide timely self-repairing, mainly on microcrack repairing without human intervention, thereby ensuring the structures remain intact for extended service life. This also supports the government’s continuous efforts to achieve sustainable development.

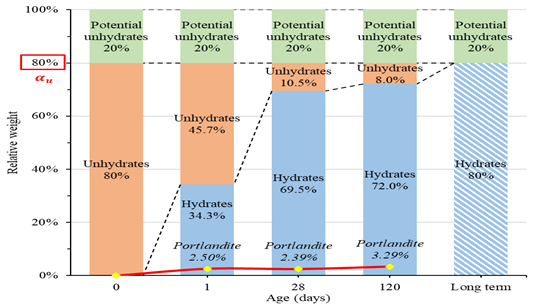

In line with the creation of a green self-healing concrete mix formulation, the project focuses on the use of sustainable and recycled materials such as ground granulated blastfurnace slag (GGBS) and silica fume as a replacement for Portland cement, which is long known for its high carbon footprint. Besides this, recycled concrete aggregate (RCA), expanded clay lightweight aggregate (LWA) and incineration bottom ash (IBA) as a replacement for natural aggregates was used, to preserve natural resources. In addition, the project also explores the use of biomaterials such as other cockle shell ash as a new form of cementitious materials in developing self-healing concrete. The initial results for the current research are encouraging. The use of GGBS at 50% replacement level has shown to perform better than pure Portland cement concrete in terms of strength recovery performance as well as crack sealing & healing ability of up to 0.15 mm.

In Eurocode 2, there are requirements for 50 years intended working life of buildings and 100 years intended working life of infrastructures (e.g. bridges) which require structures to fulfil the serviceability limit state (SLS) during these working lives. This also applies to cast in-situ and precast reinforced & prestressed concrete systems. If the crack width of a structure exceeds 0.2 mm and 0.3 mm, they are considered ‘structural’ cracks which breach the SLS for water retaining structures & general structures respectively. There are already policies in-place (for e.g. BCAPeriodical Structural Inspection) which will need documentation of SLS crack width breached and require repair of concrete by human intervention.

Hence, the R&D on self-healing concrete concept (without the need of human intervention) is particularly useful for preventing non-structural crack widths below the SLS (i.e. ≤ 0.2mm or 200µm or microcracks which are deemed ‘non-structural’) which will lead to lesser internal corrosion of steel reinforcement or prestressed steel in the concrete and enable prolonging the working life of structures. As concrete is the most widely used construction material in the world in this current era of aging structures & infrastructures especially in earlier developed countries globally, this R&D of self-healing concrete will directly contribute to a more sustainable built environment.

|

|

|

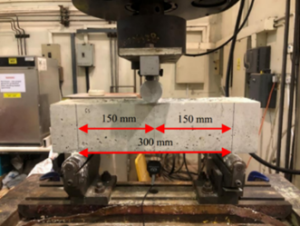

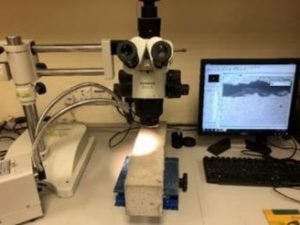

Figure 1

Figure 2 : Weight phase distribution of (a) pure Portland cement paste, (b) GGBS-blended cement paste indicating degree of hydration

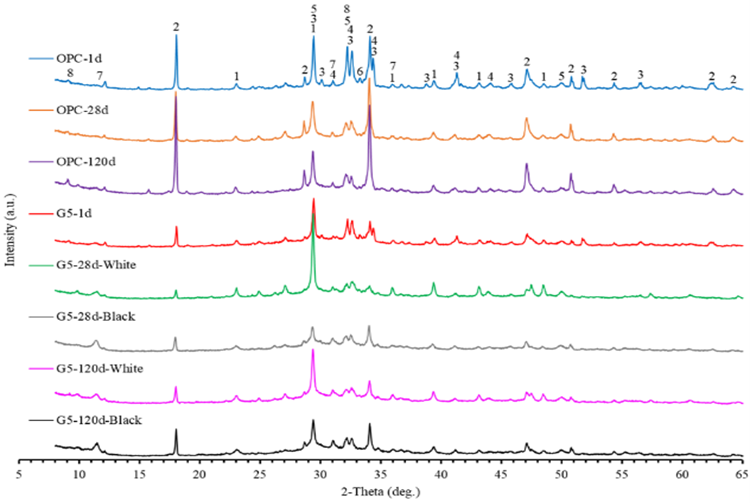

X-ray traces of OPC (reference) and G5 (50% GGBS) pastes age of 1, 28, and 120 days (1.CaCO3; 2. Ca(OH)2; 3 C3S; 4. C2S; 5. C-S-H; 6. C3A; 7.C-A-H; 8. Aft)

For more details, please contact:

Dr Kong Kian Hau

Email: ceekkh@nus.edu.sg