-

-

- Bridging Scales from Below: The Role of Heterogeneities in the Global Water and Carbon Budgets

- Increasing Occurrences of Cyanobacterial Blooms Driven by Climate Change Factors

- Carbon Capture and Utilization

- Integrated Coastal-Inland Flood Model for Climate Change

- Pathways for Sustainable and Climate-Resilient Planning of Water-Energy-Food Security Nexus

-

- Air Quality and Health: A Paradigm Shift

- Surface Water Quality and Emerging Contaminants

- Microbial detoxification of persistent organohalide pollutants (POPs)

- Nutrients Removal in Waterbodies via Sustainable Pathways

- Centre for Water Research (CWR) researchers join their forces with U of T researchers for microplastics pollution detection and control in water and wastewater

- Dealing with Hard-To-Treat Industrial Wastewater

- Valorization of Bioresources – Towards a Circular Economy

-

- Intelligent Traffic Diffusion Plan Generation, Effective Assessment and Dissemination Strategies

- Transforming Waste into Resources for Infrastructural Development

- Look-Ahead Integrated Geophysical Investigation System (IGIS) for Singapore Tunnels

- Next-Generation Airport Pavements with Full-Scale Instrumented Testing

-

- Centre for Advanced Materials and Structures (CAMS)

- Centre for Hazards Research (CHR)

- Centre for Resilient Underground Infrastructure and Engineering (CRUISE)

- Centre for Transportation Research (CTR)

- Centre for Water Research (CWR)

- Centre for Resource Circularity and Resilience (CR)2

- Centre for Offshore Research and Engineering (CORE)

- Centre for Environmental Resilience (CES)

- Safety & Health Committee

- Completed Research Projects

- Research Brief

- Achievements (in the media)

Digital Fabrication of Concrete for Sustainable and Resilient Built Environment

3D concrete printing is an emerging technology that combines digital technologies and new insights from materials technologies to allow free-form construction without the use of formwork. The project aims to develop resilient and sustainable concrete materials suitable for digital fabrication:

- Develop eco-friendly printable materials by seeking sustainable substitutes for the high-carbon footprint materials.

- Characterize the micro- and macro-structural evolution of 3D printed concrete materials from plastic to solid states.

- Evaluate the performance of 3D printed concrete in terms of strength, dimensional stability and durability.

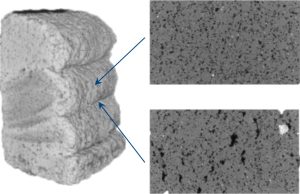

This project characterizes the microstructure of 3D printed concrete by using MIP and X-ray CT. The void size distribution reported in this study covers a wide spectrum. The mechanical performance of the 3D printed concrete, along different directions, are also investigated. This study reveals that a higher amount of macropores and large voids are present in the 3D printed samples, attributed to the movement of the printing head, elimination of vibration, and rapid moisture loss. Moreover, the morphologies of the voids are more irregular and elongated. This is more pronounced at the interlayer than in the filament, as displayed in the figure below.

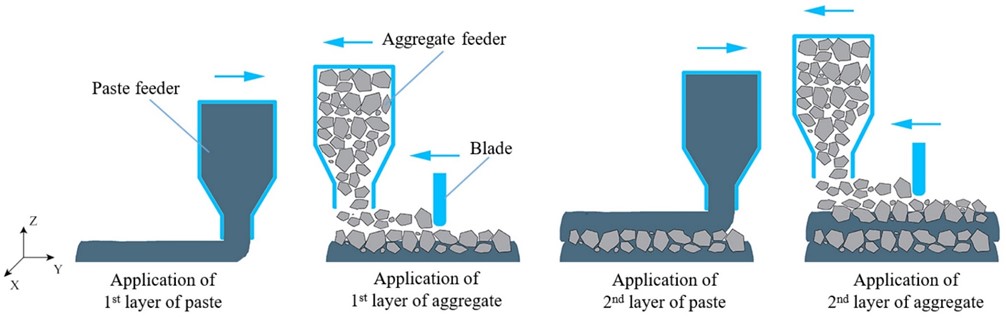

This research also investigates a novel and feasible concrete printing process, which extrudes cement-based filament onto aggregates bed to form layer-by-layer structures. Distinct from extrusion-based concrete printing, coarse aggregates are incorporated in the printing process and serve as the supporting material. A prototype printer has been successfully developed and aggregate content could reach about 40% in the printed concrete. Aggregated-bed 3D concrete printing process is shown in the figure below.

For more details, please contact:

Dr Du Hongjian

Email: ceedhj@nus.edu.sg