Date: 10-12 Sep 2024

Duration: 21 Hours

Mode Of Delivery: Face to Face

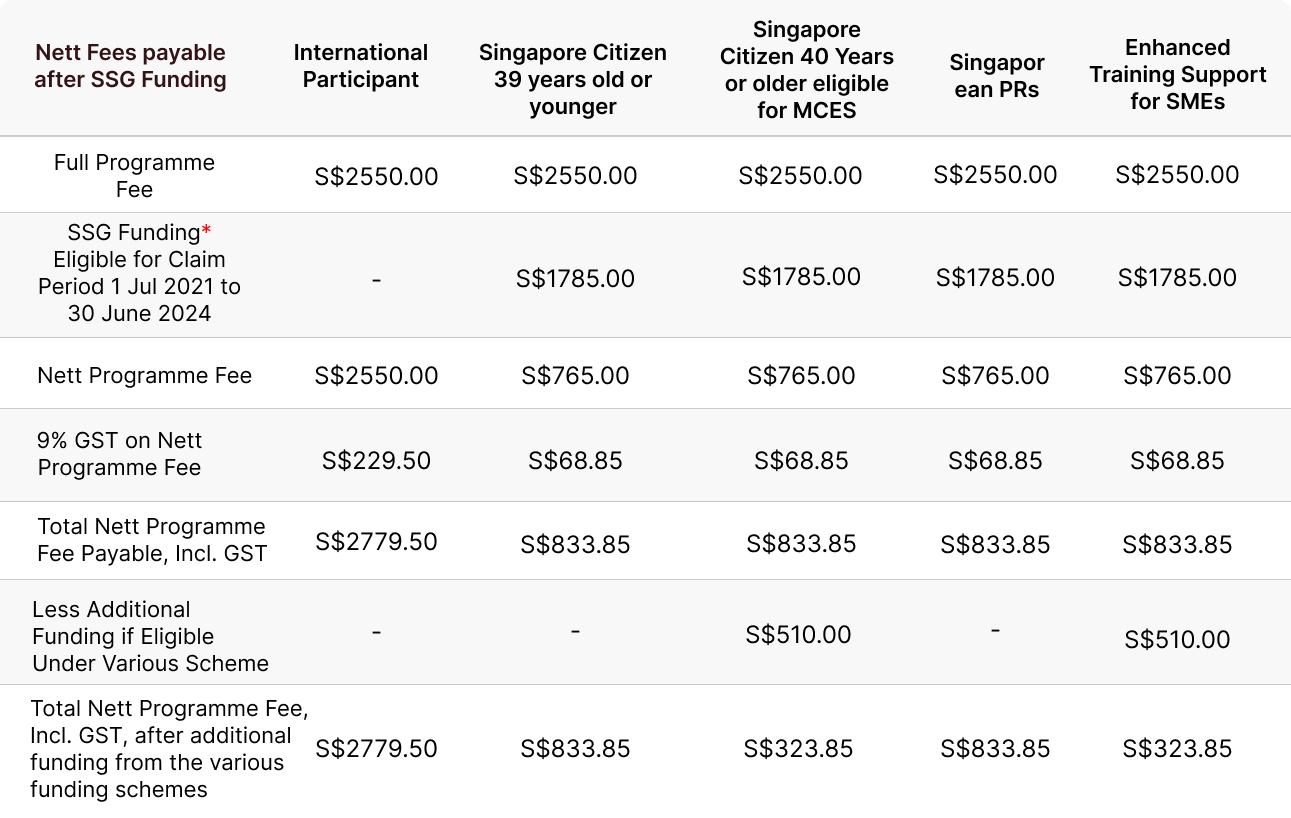

Tuition Fees: S$2550.00 (Before GST)

What You Will Learn

This is a course detailing the fundamentals of process safety and safety case. The topics covered include technical safety, major hazards assessment, the Workplace Safety & Health (Major Hazard Installation) Regulations, safety case, process safety management and an industry learning journey (to the Petrochemical Corporation of Singapore).

Safety case is a newly introduced regime in Singapore. Professional Engineers (Chemical) from diverse operational backgrounds may not have the specialised knowledge on the elements and requirements of safety case, as well as important process safety aspects in chemical plant operations.

This multi-stakeholder course is designed with the intention to bridge the gaps and offer an experiential learning benefiting both new and experienced engineers with the latest practices, regulations, and technologies.

At the end of the course, participants will be able to:

-Explain key concepts of process safety and safety case

-Demonstrate a clear understanding of chemical reaction hazards, process isolation, functional safety, fire and gas detection, ignition controls, risk assessment methodologies, consequence modelling and process safety management

-Understand the requirements of the Workplace Safety & Health (MHI) Regulations 2017

-Demonstrate the ability to develop a safety case

-Demonstrate the ability to conduct risk assessment

In collaboration with the Institution of Engineers, Singapore (IES) / IES Academy

The Institution of Engineers, Singapore (IES) was formally established on July 1966 as the national society of engineers in Singapore. IES maintains close links with professional organizations of engineers regionally and throughout the world in promoting goodwill and fellowship among all engineers in the region and internationally. IES established IES Academy (IESA) to provide professional updating and training needs of the engineering community. IESA trains some 8,000 participants annually to attain professional competencies, improve mobility, engineering leadership progression and continuous development. Accredited with ISO 29990, supported and funded by multiple partners and government agencies, IESA extends a wide reach to all branches of engineering in delivering quality learning service.

Who Will Benefit

Prospective Professional Engineer (Chemical), Safety Case Practitioners, Chemical Plant Operators, Process Engineers, Company Safety Case Team, Safety and Health Practitioners

Entry Requirements

Possess at least a Bachelor's Degree in Engineering OR Professional Engineer (PE), Chemical

Instructors

Prospective Professional Engineer (Chemical), Safety Case Practitioners, Chemical Plant Operators, Process Engineers, Company Safety Case Team, Safety and Health Practitioners

Er. Bernard Leong Lian Wah

Health, Safety and Environment Manager of Petrochemical Company

Ms. Cheng Sin Yan

Principal Safety & Risk Consultant

Dr. Foo Swee Cheng

Department of Chemical & Biomolecular Engineering

Er. Koh Boon Haw

Registered Professional Engineer with PEB Singapore

Er. Lim Liang Hong

Senior Specialist with the Major Hazards Department, Ministry of Manpower

Available Discounts and Benefits

Notes

Course Code: TGS-2020507487

*Learners must fulfill at least 75% attendance and pass all assessment components, to be eligible for SSG funding.

**Please note that the mode of delivery is subject to change in light of the COVID-19 situation.

Courses marked ‘online’ may have compulsory face-to-face sessions such as laboratory or hands-on components and details should be sought from the schools or departments before learners register for them.

Related Programmes

General Introduction of Material for Additive Manufacturing