Sustainable Innovation Studio

Do you know that only 7.2% of the global economy is circular? This means that more than 90% of materials are lost, wasted, or unused for long periods. Unfortunately, this situation is expected to worsen, and experts predict global waste production will increase by 70% by 2050. If this trend continues, pollution levels will rise, and we will need to extract more resources, which will cause irreversible environmental damage.

To address this challenge, we need to shift towards a circular economy that focuses on reducing waste, recovering resources at the end of a product's life, and reusing them in production. Successfully enacting this change will significantly decrease the negative impact on the environment. It will also create new jobs and commercial opportunities for businesses and improve the efficient use of natural resources.

Aside from reducing waste, Singapore also needs to reduce its carbon footprint especially in the energy sector. On a national scale, Singapore faces unique challenges due to its limited access to renewable resources and heavy reliance on natural gas, which currently supplies over 95% of its electricity. To meet its 2030 climate targets and move toward net-zero emissions by 2050, Singapore need to improve energy efficiency in its built environment and industries.

With significant environmental and economic benefits, many organisations are actively exploring ways to achieve sustainability. As leaders of tomorrow, we offer this studio as a platform for you to learn about sustainability and apply your creativity and innovativeness to help our industry partners accelerate their efforts toward achieving sustainability. Join us and help shape the future!

Project supervisors:

- Dr Jovan Tan (jovan@nus.edu.sg)

- Dr Elliot Law (elaw@nus.edu.sg)

Studio timeslot in Semester 2 AY2025/2026:

- Thursday 1 pm to 4 pm

Examples of past projects:

Closed-loop mechanical recycling with microplastic mitigation

In this project, we developed a novel asphalt mix incorporating ceramsite and waste glass to reduce overall road temperatures and mitigate the urban heat island effect.

In this project, we developed a new adhesive that acts like a sacrificial layer to improve recyclability of single-use beverage cartons by enabling the layers of the carton to be more easily separable.

In this project, we designed a process to extend the shelf life of spent coffee grounds such that they can be repurposed into all-natural treats like cookies and granola, transforming coffee waste into a food-safe ingredient to brew a more sustainable future.

In this project, we developed a novel asphalt mix incorporating ceramsite and waste glass to reduce overall road temperatures and mitigate the urban heat island effect.

This project aims to develop an optimised fermentation process that converts locally abundant brewer's spent grain into mycoprotein, effectively transforming this waste into a sustainable protein source to address food security and food waste challenges in Singapore.

Our project develops a novel, sustainable process to produce lactic acid through bacterial fermentation of municipal food waste, reducing carbon emissions and diverting waste from incineration.

Next-generation sustainable beverage carton

Project partner: Lovearth Water Pte Ltd

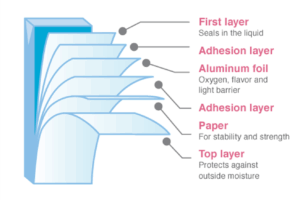

Beverage cartons are perceived to be more sustainable because they are mainly paper-based, but are not as eco-friendly as they seem. Globally, only 26% of beverage cartons are recycled. This low recycling rate is due to their complex multilayer composition which comprises functional and adhesive layers. The multilayer structure of beverage cartons significantly complicates recycling as some of the composite layers are difficult to break apart and require specialised recycling equipment that is not widely available. Yet, to be truly sustainable, material separation is essential for effective recovery and reuse.

Thus, building on an existing sacrificial-layer proof-of-concept solution, this project aims to develop and prototype a functional carton with easily separable layers for high-quality fiber and polymer recovery, ensuring true circularity without compromising shelf life, barrier properties, or manufacturability. This project thus seeks to advance the development of a fully recyclable beverage carton that maintains the low-carbon advantages of current paper-based cartons while making end-of-life separation and recycling easier.

While this project is most suitable for students from Chemical Engineering, Materials Science and Engineering, and Mechanical Engineering, we welcome students from all disciplines who are passionate about sustainability to join this project!

Closed-loop bottling ecosystem

Project partner: Lovearth Water Pte Ltd

Do you know that Singapore is one of the world's greatest consumers of single-use plastics? Yet, in 2022 the domestic plastic recycling rate in Singapore is only about 6%. The vast majority of plastic waste are incinerated, with the incineration ash buried at Pulau Semakau that is expected to be fully filled by 2035.

While many organisations such as hotels and food and beverage operators are aiming to stop giving out plastic bottled water in favour of getting more patrons to switch to their own reusable bottles, bottled water is still needed in many different settings because of its convenience and utility. Even though there are already other alternatives to single-use plastic water bottles such as beverage cartons, they may be less eco-friendly compared to plastic bottles. This is because they are not generally not recyclable due to their multilayered design. Advances in recycling technology can improve the recyclability of beverage cartons, but very few facilities are equipped with such technology.

Thus, this project aims to create a scalable closed-loop water bottling ecosystem in the hospitality and food and beverage industries to transition from single-use water packaging to more sustainable options without sacrificing convenience and functionality. With support from Lovearth and their hospitality partners, this project will explore different approaches for supplying, collecting, and upcycling of ecofriendly water packaging.

While this project is most suitable for students from Materials Science and Engineering, Industrial and Systems Engineering, and Business, we welcome students from all disciplines who are passionate about sustainability to join this project!

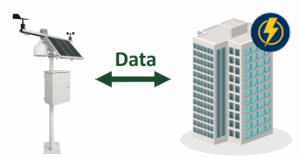

Intelligent weather-responsive building management system

Project partner: NUS University Campus Infrastructure

Do you know that buildings in Singapore consume about half of the country's electricity? At the same time, energy consumption in the building sector is trending upwards due to increasing population and higher economic activity. Thus, improving energy efficiency in buildings while ensuring their liveability is a key pillar in our efforts to meet the targets in the Singapore Green Plan.

In line with the national agenda, NUS aims to be a smart, sustainable and resilient campus by 2030. Aside from designing new buildings and retrofitting existing ones to reduce solar gain and improve natural ventilation, NUS is also working to optimise building operations in order to reduce energy usage through active and smart measures that take into account real-time conditions and occupancy.

Hence, working together with the NUS University Campus Infrastructure team, this project aims to create an integrated system that continuously gathers real-time weather data from weather stations to intelligently and automatically adjust the air conditioning and mechanical ventilation controls (e.g. setpoints) in a building. By dynamically adjusting building operations in real-time based on current and forecasted weather conditions, the system seeks to reduce energy consumption, improve occupant comfort, and lower operational costs—all while preserving indoor air quality.

While this project is most suitable for students from Computer Engineering, Electrical Engineering, Industrial and Systems Engineering, Infrastructure and Project Management, and Mechanical Engineering, we welcome students from all disciplines who are passionate about sustainability to join this project!

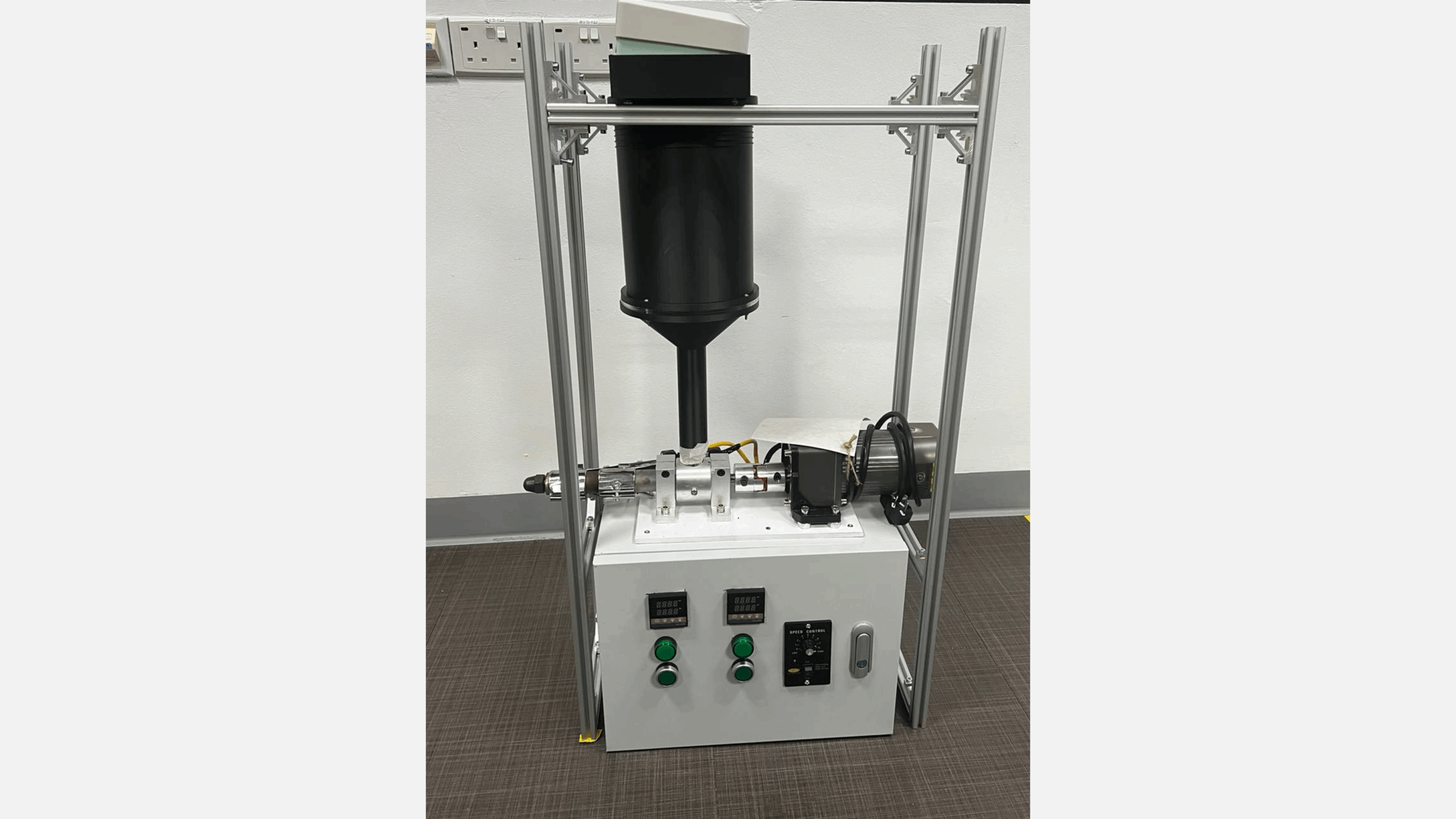

Transforming PP5 plastic waste into 3D printing filaments

Project partner: NUS University Campus Infrastructure

PP5 plastics, made from polypropylene, are often not recycled due to several practical and economic challenges. They require specialised sorting and processing, which many recycling facilities are not equipped to handle efficiently. Additionally, the low market demand for recycled PP5 and the relatively low value of the material make it less attractive for recyclers to invest in its recovery and reuse. As a result, most PP5 plastic waste are incinerated or end up in landfills.

To address this problem, this project aims to design a self-contained process and system to convert PP5 plastic waste into 3D printing filaments which can be recycled continuously to improve circularity of the material. Using the NUS campus as a testbed, the solution should be readily deployable and scalable. The project partner will provide mentorship, test-bedding opportunities for a small-scale pilot facility on campus, plastic waste as feedstock, and potentially a project grant.

While this project is most suitable for students from Industrial and Systems Engineering, Materials Science and Engineering, Mechanical Engineering, and Business, we welcome students from all disciplines who are passionate about sustainability to join this project!

Food waste to food: valorising coffee waste

Project partner: the moonbeam co.

the moonbeam co. is gaining momentum in the food tech industry by transforming spent coffee grounds into baked goods. Currently the company manages centralised waste streams (such as from large-scale brewing operations) but there are significant untapped resources from decentralised waste such as spent grounds from espresso machines used in cafes and smaller food and beverage establishments.

This project aims to develop a proof-of-concept solution that can efficiently process such decentralised waste streams on-site and convert them into baked good. The challenge in this project is to decentralise the moonbeam co.'s existing process, enabling local processing without relying on a central hub, while maintaining product quality, scalability, and sustainability. The scope of work may include the following:

- Designing a system that collects, processes, and integrates spent espresso grounds into a consistent baking mix.

- Prototyping a machine that can autonomously operate in smaller cafes or offices.

- Ensuring the process is energy efficient and retains the nutritional properties of the grounds.

- Scaling the solution in a manner that ensures cost-efficiency as operations are expanded.