IntelLift: An intelligent self-balancing system for lifting of PPVC modules

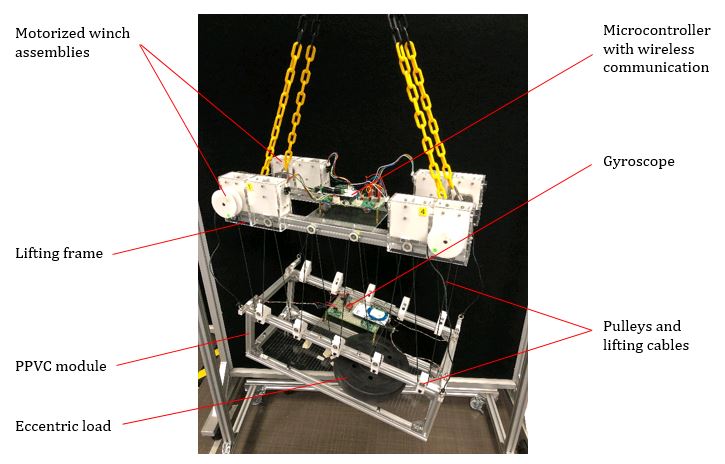

Key components of a scaled prototype of IntelLift

Project Motivation

To improve productivity in the construction sector, the Singapore government has been pushing aggressively for the adoption of the prefabricated prefinished volumetric construction (PPVC) method where large modular room-sized units are manufactured in factories and delivered to construction sites to be installed using cranes. However, one of the key challenges in PPVC especially for concrete modules is keeping these modules level during lifting and installation. Since the modules come complete with interior furnishings and are typically asymmetrical in their design, they usually tilt when they are lifted because their centre-of-gravity does not coincide with the centre-of-gravity of their lifting frame and the lifting hook of the crane. Current approaches to ensure the modules are level during lifting are time-consuming and labour-intensive because engineers have to calculate the position of the centre-of-gravity for each PPVC module, while workers have to repeatedly measure the inclination angle of the module and make manual adjustments to the length of lifting cables before the module is level. Therefore, this project aims to design an intelligent and fully automated solution in order to reduce the amount of time and manpower required and also increase safety on site.

Design

The IntelLift is a lifting frame plus sensor package which is integrated with a gyroscope, microcontroller, and motorized winches. The gyroscope is mounted on the PPVC module to detect its imbalance, after which the microcontroller calculates the amount of adjustment that needs to be made in each lifting cable and then actuates the motorized winches to execute the adjustments. Using a proportional-integral-derivative control algorithm, this correction process progresses in an automatic, incremental, and iterative manner until the module is level. Wireless communication is adopted between the gyroscope which is placed on the PPVC module and the microcontroller which is mounted on the lifting frame, and also between the microcontroller and the operator on the ground. Preliminary tests on a 1:15 scaled prototype of the IntelLift have shown that the proposed solution is able to achieve a balancing accuracy of ±0.5° within a few minutes.

Project Team

Students:

- Ang Beng Heng (Mechanical Engineering, Class of 2020)

- Chew Xiu Zheng (Civil Engineering, Class of 2020)

- David Lee Kwok Hung (Electrical Engineering, Class of 2020)

- Lee Jerome (Civil Engineering, Class of 2020)

- Wang Enze (Mechanical Engineering, Class of 2020)

Supervisors: