Automation and Robotics

This studio offers students the opportunity to design and prototype automation and robotics systems that address practical challenges in sectors such as manufacturing, logistics, or healthcare. Students will engage with mechanical design, sensor integration, and control programming to develop responsive and efficient robotic solutions. Projects in this studio emphasises system-level thinking, user interaction, and iterative prototyping.

Project supervisors:

- Mr Chew Wanlong, Nicholas (nickchew@nus.edu.sg)

- Mr Keith Tan (keithtcy@nus.edu.sg)

Studio timeslot in Semester 2 AY2025/2026:

- Thursday 1 pm to 4 pm

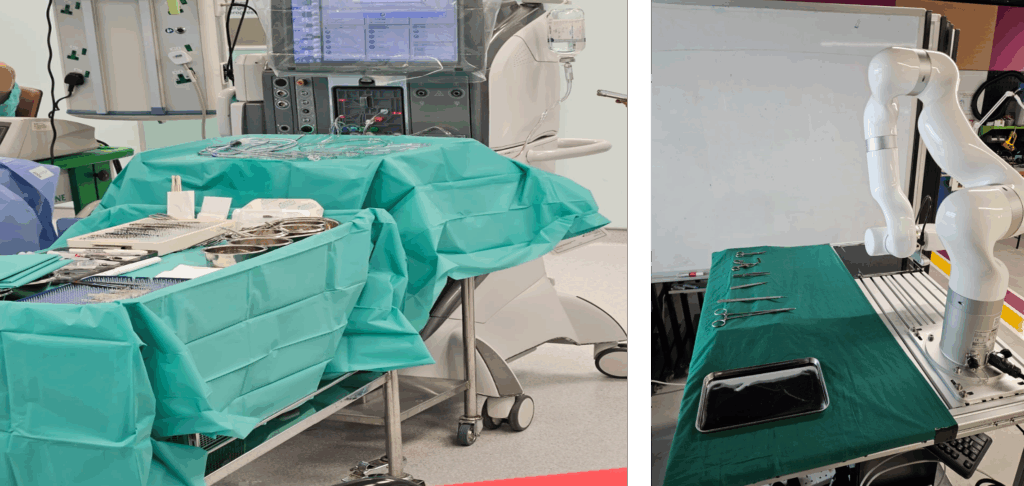

VLM-assisted ophthalmic surgical tools decluttering

Project partner: Singapore National Eye Centre (SNEC)

Cataract surgery is one of the most frequently performed procedures worldwide, placing heavy demands on nurses who must manually sort and disinfect delicate ophthalmic instruments between operations.

In order to address this, the project aims to develop an AI-driven robotic system using a UFactory collaborative arm to automate the sorting and decluttering of surgical tools, integrating vision-language models (VLMs) for intelligent object recognition and classification. In addition, students will design and prototype soft grippers capable of safely handling instruments of varying shapes and materials.

The outcome will enhance surgical workflow efficiency, reduce manual workload, and advance human-robot collaboration in medical environments.

While the use of robotic grippers can greatly enhance the efficiency of pick-and-place tasks, the current methods for designing these grippers are manual and experience-driven. These processes are time-consuming and lack the adaptability needed to accommodate changes in manufacturing requirements. There is a clear need for an innovative design approach that enables rapid iterations in the creation of task-specific robot grippers. Achieving this level of versatility in robotic grippers remains a significant challenge. Striving for a level of versatility akin to human capabilities with a single gripper and a reduced number of actuators is a complex task. The search for an optimal method to achieve this remains an open area of research in both robot manipulation and gripper development.

Pre-requisite: students who embark on this project must have prior knowledge of ROS 2.0.

ROS-powered de-littering robot for maker space

Project partners: Advantech and Mitsubishi Robotics Division

We have has recently developed a mobile manipulator consisting of a Mitsubishi MELFA collaborative robot arm mounted on a SESTO autonomous mobile robot (AMR) and powered by an Advantech industrial onboard computer. This project invites students to extend the system’s capabilities by enabling it to autonomously detect and collect litter around the CDE Innovation & Design Hub. Students will integrate machine vision, motion planning, and wireless communication modules to achieve robust performance in real-world outdoor conditions. Key challenges include visual perception under variable lighting, weather resilience, end-effector actuation and network reliability, offering hands-on experience in field robotics, AI-based perception, and mobile manipulation.

Reinventing the everyday laundromat

Project partners: Hub360 and Fresh Laundry Pte Ltd

Did you know the first laundromat opened in Texas in 1934 during the Great Depression, offering pay-per-use washing machines to families who couldn’t afford their own?

Fast forward nearly a century, and while machines have become more advanced, the core laundromat experience has barely changed. In Singapore’s residential estates, laundromats remain largely traditional — rows of machines, coin slots, and manual loading/unloading.

This presents a golden opportunity for innovation: what if we could completely reimagine the laundromat for the digital age?

Project aim — break the mould with tech-driven innovation:

This project aims to disrupt the status quo by designing a new-age laundromat powered by apps, AI, sensors, and robotic arms. The goal is to create a smart, sustainable, and space-efficient laundromat that not only enhances customer convenience but also minimides manpower needs. Just as families once relied on public laundromats due to cost, we envision a future where they choose them for efficiency, automation, and space-saving — eliminating the need for bulky washing machines at home.

Possible scope and innovation directions:

- Smart machine integration: retrofit existing industrial washers and dryers to work seamlessly with robotic arms for automated loading/unloading.

- Sensor-driven insights: embed IoT chips and sensors to monitor machine usage, predict maintenance, and optimise energy consumption.

- Digital experience: conceptualise and design mobile apps that will complement the capabilities developed.

Design of automated flange connection system for heavy duty applications

Project partner: SPM Oil & Gas / Caterpillar Inc

In heavy industries, flange connections are critical for creating secure seals between high-pressure components like valves and risers. These flanges can be huge and must endure extreme forces and harsh conditions, which makes manual tightening a labor intensive process. The automotive industry on the other hand has adopted automation for its hub connections, improving speed, accuracy and safety. We are looking to implement a similar automated solution that can handle a wide variety of flange sizes and ensure consistent, reliable connections without manual intervention.

This project aims to develop a system capable of automatically tightening and securing flange connections of varying sizes, replacing the current manual method.