Print×Lab: A novel device for on-site personalization of drug dosages

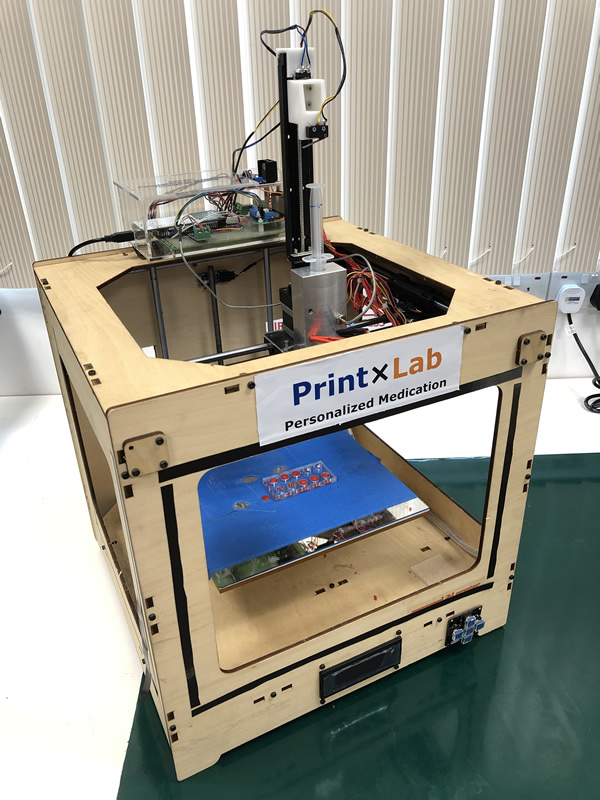

Perspective view of Print×Lab

Project Motivation

The dosage of a drug required to treat an ailment depends on many factors such as age and weight of a patient, severity of the condition, and potency of the drug. However, drug tablets and capsules sold in clinics, hospitals and pharmacies typically come in standard dosages. This makes it difficult for doctors and pharmacists to prescribe the precise dosage that is required based on the needs of individual patients. Hence, it leads to problems such as less-than-ideal duration between dosages or the need for patients to break large tablets into smaller doses that are neither definite nor predictable.

Thus, this project aims to design a means for healthcare professionals in clinics, hospitals and pharmacies to provide on-site customisation of drug dosages based on the needs of individual patients in a precise, efficient, and reliable manner.

Design

The Print×Lab is a device that is designed for on-site personalization of drug dosages. It leverages on 3D printing technology that does not require the use of high temperatures which could negatively affect the performance of the drugs. It comprises a modified print head and printing table that work on a normal 3D printing platform. The customised print head contains a heating system and a dispensing system that are designed to function with a disposable syringe which contains the active pharmaceutical ingredient (API) and its excipient. The dispensing system consists of a vertical linear actuator which is powered by a servo motor, and the actuator interfaces with the plunger of the syringe via a contact bracket with limit switches.

To operate the device, a user would first insert the syringe with the API and excipient into the heating block which forms part of the heating system, and then input the target dosage and number of tablets to print. The heating block would then heat the contents of the syringe up to a pre-determined temperature that is suitable for dispensing. Each tablet would thereafter be formed one at a time on the printing table and they would be cooled to speed up the solidification process. Preliminary tests on the device have shown that it is able to achieve an output dosage accuracy and consistency of up to 95%.

Project Team

Students:

- May Maung Zaw (Biomedical Engineering, Class of 2019)

- Teo Wei Jie Tristan (Biomedical Engineering, Class of 2019)

Supervisors: