Robotic modular bioreactor for efficient immune cell manufacturing

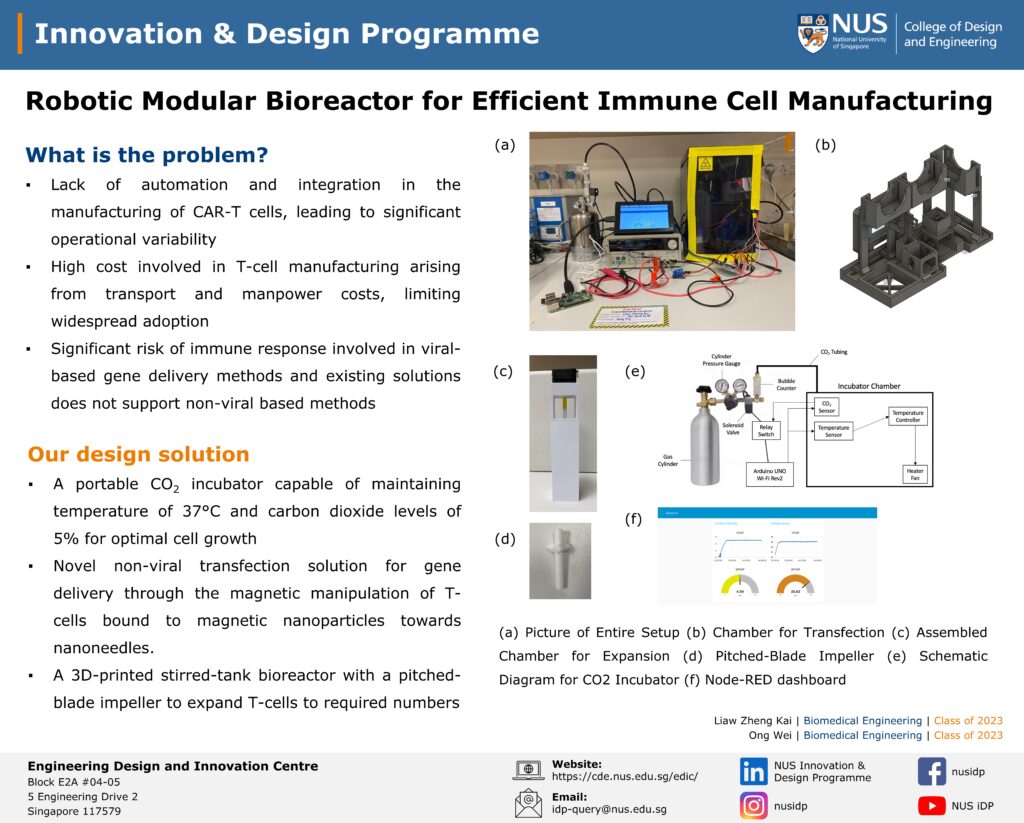

Manufacturing CAR-T cells is a complex process requiring the collection of T cells from autologous or allogeneic sources and subsequent activation, gene delivery, and expansion of the modified cells. However, the lack of automation and integration in the manufacturing process causes significant variability and drives up production costs. There is also a significant risk of immune response involved in viral-based gene delivery methods, but existing methods do not support non-viral based methods.

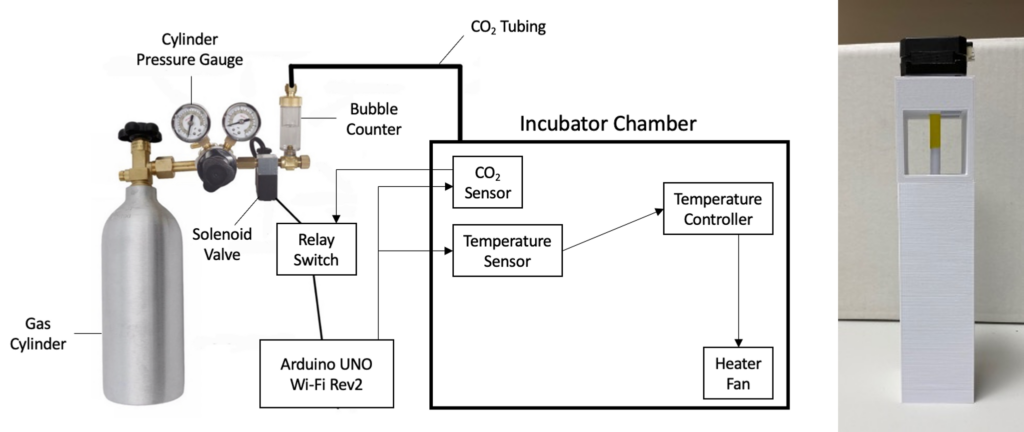

In this project, a modular bioreactor was designed to improve the process of immune cell manufacturing. Magnetic nanoparticles are used to bind to Jurkat cells for magnetic cell manipulation, allowing for cell isolation and a novel non-viral transfection solution using nanoneedles for mechanical injection for gene delivery. It is also capable of maintaining temperature of 37°C and carbon dioxide levels of 5% for optimal cell growth and uses a pitched-blade impeller to expand immune cells to required numbers.

Project Team

Students:

- Liaw Zheng Kai (Biomedical Engineering, Class of 2023)

- Ong Wei (Biomedical Engineering, Class of 2023)

Supervisor:

- Tay Kah Ping, Andy (bietkpa@nus.edu.sg)