SpenVI: Customised polypills to simplify complex medication regimen

Project Motivation

Elderly patients who have multiple chronic illnesses such as diabetes, hypertension, and heart disease often need to take numerous medications to manage their health condition. Most of these patients have complex medication regimen which requires them to consume six or more different medication – a practice which is known as polypharmacy – in different doses and at different times of the day. However, many elderly patients have difficulties adhering to their complex medication regimen because of decreased cognitive functions as they age and lack of motivation due to the negative perception and perceived hassle caused by the high pill burden.

Therefore, this project aims to simplify complex medication regimen through the use of customisable polypills. Instead of having to consume multiple pills in different dosages at different times of the day, a patient may only need to consume one type of pill once or twice a day. This could greatly improve medication adherence among patients who require polypharmacy especially the elderly. Moreover, it is also possible to customise the combination of drug types and dosages for every patient, which has the potential to improve treatment efficacy.

Design Solution

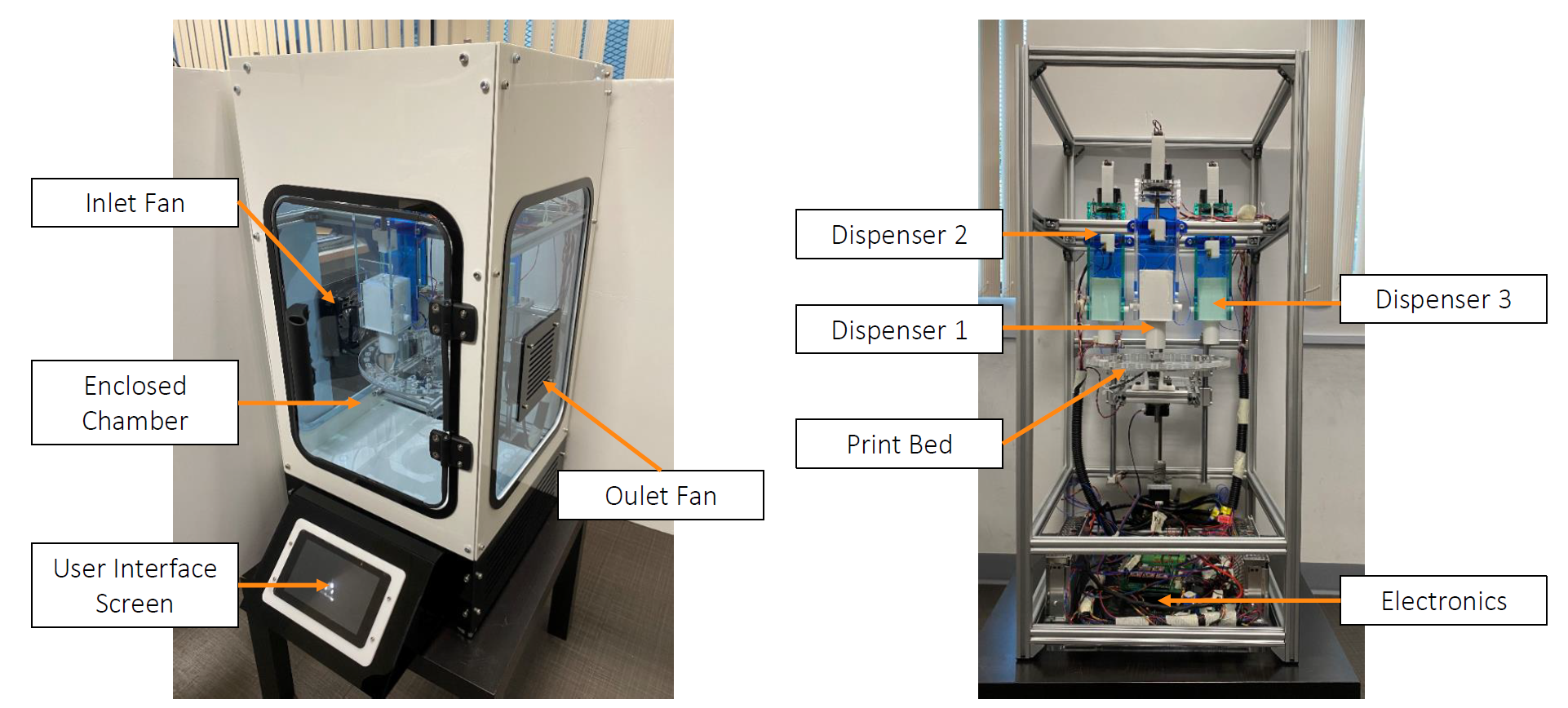

The polypill production device made in this project, SpenVI, is designed to fabricate multi-layered polypills in a convenient and automated manner. Unlike current 3D-printing based methods such as fused-deposition modelling and solid-state extrusion, SpenVI is a first-of-its-kind device which can produce polypills with customised drug combinations and dosages without requiring the use of very high temperatures or long production times.

The device contains multiple dispensing units and a rotary print bed that are housed in a fully-enclosed chamber. Each dispensing unit is designed to melt a solid feedstock of a drug, which is contained in a disposable syringe, and dispense a specific amount of the feedstock onto a pill mould on the print bed based on the required dosage. The feedstocks are dispensed in a synchronised fashion in order to produce a batch of multi-layered polypills in a single print job. The device also includes a touchscreen that is used to select and run a print job, and displays on-screen instructions and updates for the user of the device during the entire production process.

A proof-of-concept prototype of the device was able to achieve heating temperatures that are less than half of that used in conventional approaches, and a production time that is up to ten times faster compared to existing solutions. The prototype was also able to achieve an accuracy of ±5% of target dosage value of each layer in the polypill.

Project Team

Students:

- Alicia Ng Mui Shen (Biomedical Engineering, Class of 2020)

- Ang Beng Heng (Mechanical Engineering, Class of 2020)

- Chua Pei Ling (Materials Science & Engineering, Class of 2020)

- Harith Hakim B Hesheam (Mechanical Engineering, Class of 2020)

- Rebecca Kim Yun Wen (Biomedical Engineering, Class of 2020)

- Soh Li Jie (Biomedical Engineering, Class of 2020)

Supervisors:

- Dr Elliot Law (elliot.law@nus.edu.sg)

- Ms Wong Kah Wei (clbwkw@nus.edu.sg)

- Mr Eugene Ee (wheee@nus.edu.sg)