Intelligent Surgical Tools Inspection System

Project Motivation

Surgical instruments must undergo a rigorous process of cleaning, sterilising and inspection after surgeries to ensure their proper maintenance, increase longevity of tools and prevent health hazards due to contaminated tools. A critical step involved in doing so is the visual inspection conducted by medical staff. The accounting of tool kits is often a labour intensive and mundane task which could be easily automated. Feedback from stakeholders indicate that human errors in monitoring and inspection do occur occasionally, resulting in patient harm if unidentified or loss of time during surgery if identified by surgeons. This can be attributed to subtle differences and small features of tools as well as the strenuous effect on the eyes. Existing solutions to this issue mostly focus on the identification of tools. However, the area of identifying mechanical faults and impurities in surgical tools via computer vision remains largely unexplored. Hence, this project aims to design a solution to identify such faults and residues, particularly in ophthalmic surgical tools, using a combination of robotics and computer vision. We aspire to aid in more rigorous inspection of the tools while reducing the burden on the nurses.

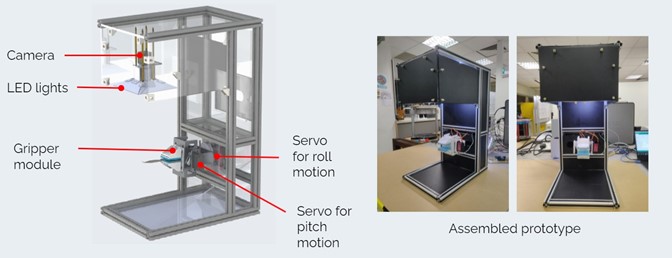

Design

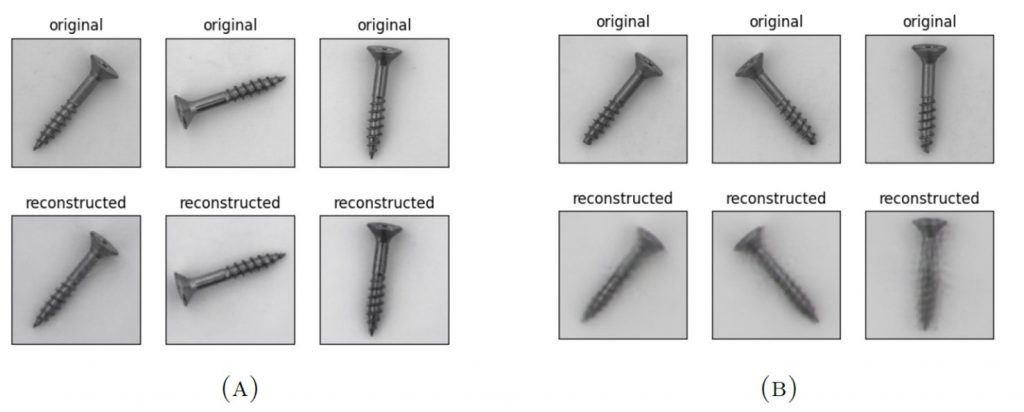

Our design consists of a two-axis gripper mechanism to grasp the surgical tool and rotate as needed and a high-resolution camera system to capture images for inspection. A deep convolutional autoencoder, trained on defect-free tools, is used to detect any impurities and irregularities on the tool such as cracks, stains, biological residue etc. from the captured image. Structurally, the gripper jaw has a silicone padding to increase the tools’ area of contact with the gripper designed to be removable, complying with the stakeholder requirement of maintaining sterility. The system is designed to process only those tools which the user wishes to inspect carefully since accuracy of the tool inspection is prioritized.

The physical set up of the proposed design with the gripper mechanism for movement of tools for inspection (roll and pitch) allows the system to inspect all parts of the tool. A system throughput of 2 tools per minute is achieved, and the design meets the size constraints set by the stakeholders. The deep learning model proposed also satisfies the design requirement of having 95% true-positive rate for identifying various defects in the surgical tools.

Project Team

Students:

- Srishti Ganguly (Mechanical Engineering, Class of 2021)

- Varun Shaji (Electrical Engineering, Class of 2021)

Supervisor:

- Tang Kok Zuea (engtkz@nus.edu.sg)