Innovative design for composite tooling

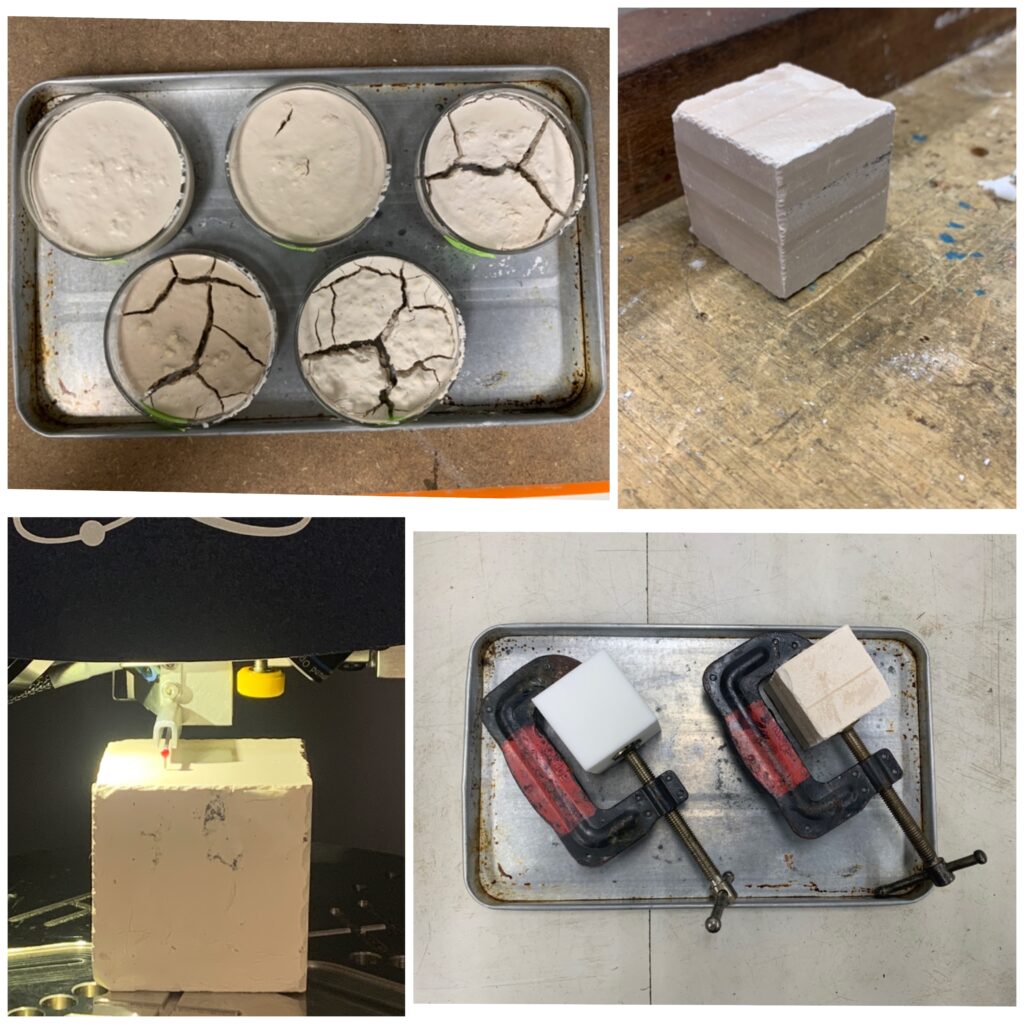

The use of one-time, non-reshapeable and non-redesignable moulds for producing carbon fibre reinforced polymer (CFRP) composite parts results in waste of raw materials, high fabrication cost, and longer lead times for manufacturing. To address these problems, we designed clay moulds for production of CFRP composite parts. The clay moulds are 7.5 times cheaper than those made of other materials such as ABS, allow the curing process to run up to 10 times faster compared to other materials, and can be reused multiple times by simply adding water to reshape them.

Project Team

Student:

- Rushabh Gala (Materials Science and Engineering, Class of 2024)

Supervisors:

- Mr Kenneth Neo (kenneth@nus.edu.sg)

- Mr Lim Hong Wee (lhw@nus.edu.sg)