Optimising workflow efficiency in a packaging line via automation

Product packaging is a manpower-intensive process. Workers need to feed products into a labelling machine, receive the products from the machine, and pack them into cartons. Balancing the feeding rate of products into the labelling machine with the packing rate of labelled products into cartons is challenging to achieve using existing solutions.

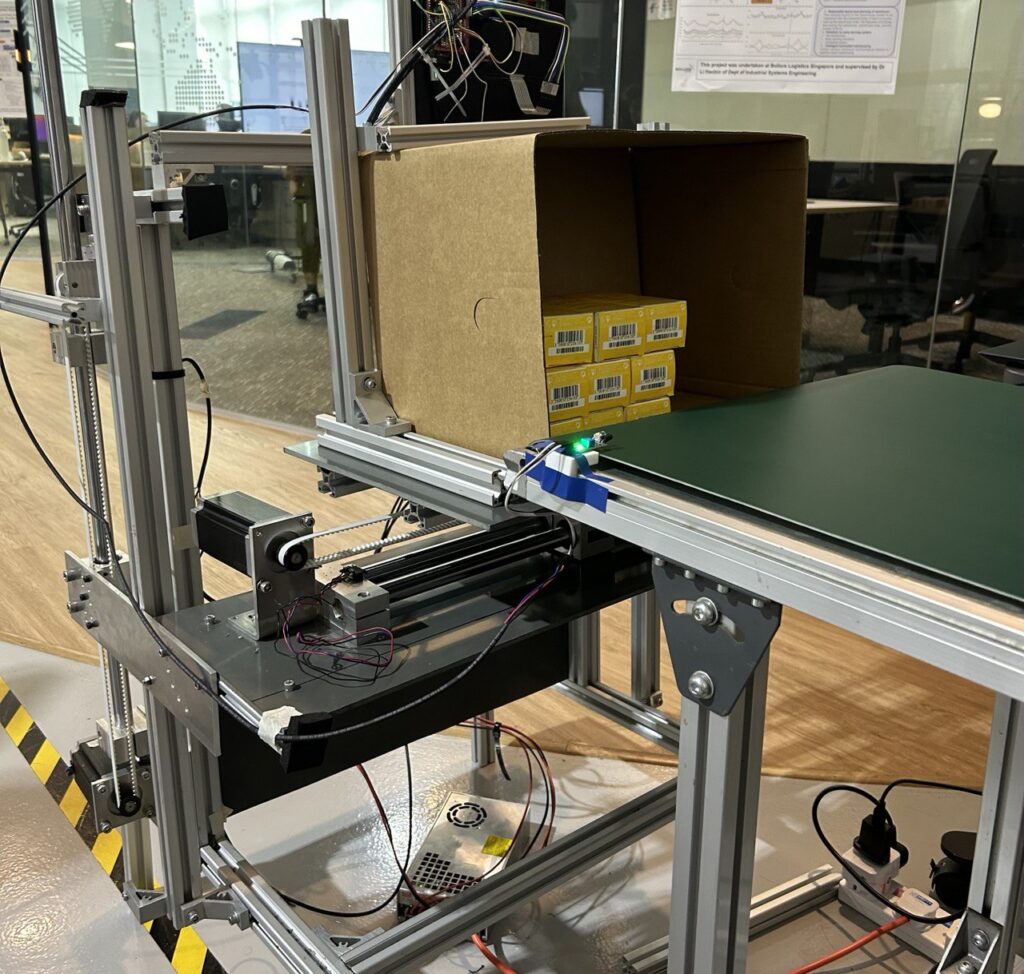

In this project, we designed an automated system to optimise the workflow efficiency in a packaging line. It comprises a compact and portable stepper motor belt system that mimics sideways packing by workers. The system is easily reconfigurable for different products, and is able to monitor and manage multiple packing machines simultaneously.

Project Team

Students:

- Keanne Lim Jun Yong (Mechanical Engineering, Class of 2024)

- Ng Qi Hao (Electrical Engineering, Class of 2024)

Supervisor:

- Mr Soh Eng Keng (ek.soh@nus.edu.sg)