Valorisation of municipal food waste into lactic acid

The market demand for lactic acid - a chemical used in various industries like food, cosmetics, and plastics - is projected to increase by 86.7% by 2030. However, the current approach for lactic acid production presents environmental and ethical concerns as it utilises carbohydrate-rich purpose-grown crops such as sugarcane and corn as feedstock. This approach diverts valuable agricultural resources, like land and produce, from food production. This problem is further exacerbated by the significant carbon emissions due to the use of fertilisers.

At the same time, more than one billion tonne of food waste is generally globally every year, much of which is incinerated or buried in landfills. This also leads to environmental problems such as carbon emissions and land pollution. Yet, similar to purpose-grown crops, food waste has high carbohydrate content which makes it a possible alternative source of carbohydrate for lactic acid production. The use of food waste for lactic acid production could maximise its nutrient value, which would

otherwise be lost, and help retain its carbon content, reducing emissions typically produced through incineration and landfilling.

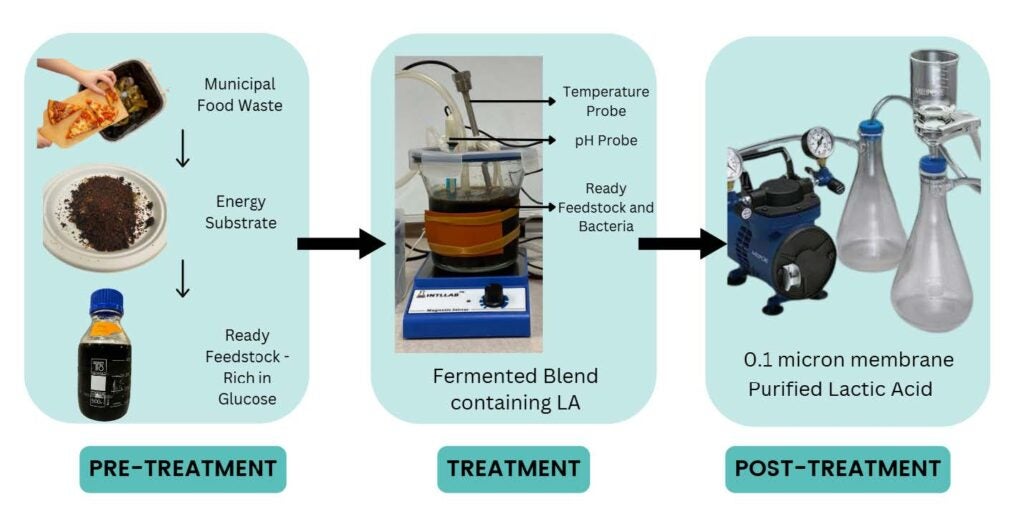

In this project, we conducted lab-scale experiments to determine the feasibility of using municipal food waste as feedstock to produce lactic acid. We designed a three-phase process which include pre-treatment of municipal food waste to produce a feedstock that has high glucose content, conversion of glucose to lactic acid using bacterial fermentation, and purification the lactic acid produced using membrane filtration.

Overall, our results show that a relatively high conversion efficiency of municipal food waste to lactic acid could be achieved while reducing waste and carbon emissions compared to conventional methods. Thus, the proposed approach not only offers potential for reducing waste volume and carbon emissions but also presents a solution that aligns with the growing demand for sustainability in the chemical manufacturing sector.

Project Team

Students:

- Adhvika Mohan (Chemical Engineering, Class of 2026)

- Aditi Joshi (Civil Engineering, Class of 2026)

- Harini Ravichandran (Materials Science & Engineering, Class of 2026)

- Tan Mei Ling, Felicia (Chemical Engineering, Class of 2026)

- Zhu Fangze (Environmental Engineering, Class of 2026)

Supervisors:

- Dr Jovan Tan(jovan@nus.edu.sg)

- Dr Elliot Law (elliot.law@nus.edu.sg)