Electric powered canard rotor wing system

Project Motivation

Drone deliveries are a last-mile delivery option that utilizes drones to replace traditional last-mile delivery methods. While the drone delivery industry is relatively new today, it is projected that the market size will reach USD 27 billion by 2030. Most drone delivery companies today utilize multi-rotor drones to perform drone deliveries. These multi-rotor drones have a simple mechanical structure and control system with parts that can be easily sourced, making them accessible for many companies.

However, multi-rotor drones are not very efficient in flight. They are inherently unstable and to maintain control and balance in flight, it needs to be constantly making corrections to accelerate or decelerate each rotor, in an energy-consuming process. Additionally, according to actuator disc or momentum theory, a single large rotor is more energy efficient at providing thrust than multiple smaller rotors. A helicopter would hence be more efficient than a multi-rotor drone.

But most importantly, multi-rotor drones do not have the long-range capabilities of fixed-wing aircraft. To fly forward, the multi-rotor drone would tilt forward, and in this position, a component of thrust from the rotors is used to push the drone forward. To maintain altitude in forward flight, the rotor thrust must be increased. On the other hand, a fixed-wing aircraft can maintain forward flight with lower energy consumption. These inefficiencies limit the range of multi-rotor drones, making it difficult to perform deliveries that require travelling large distances.

Design Solution

To improve the range capability of drones, companies such as Amazon and Google have turned towards VTOL (Vertical Take-Off and Landing) drones, which are a family of drones that combines the vertical take-off and landing capabilities of multi-rotor drones with fixed-wing aircraft.

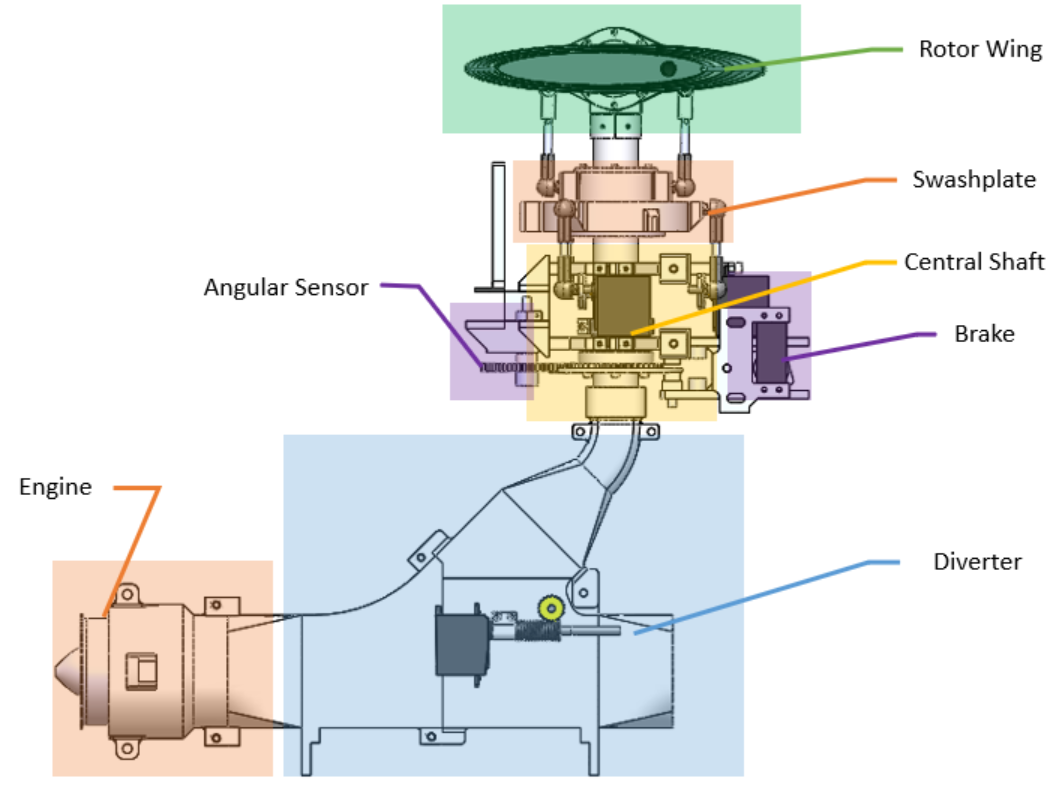

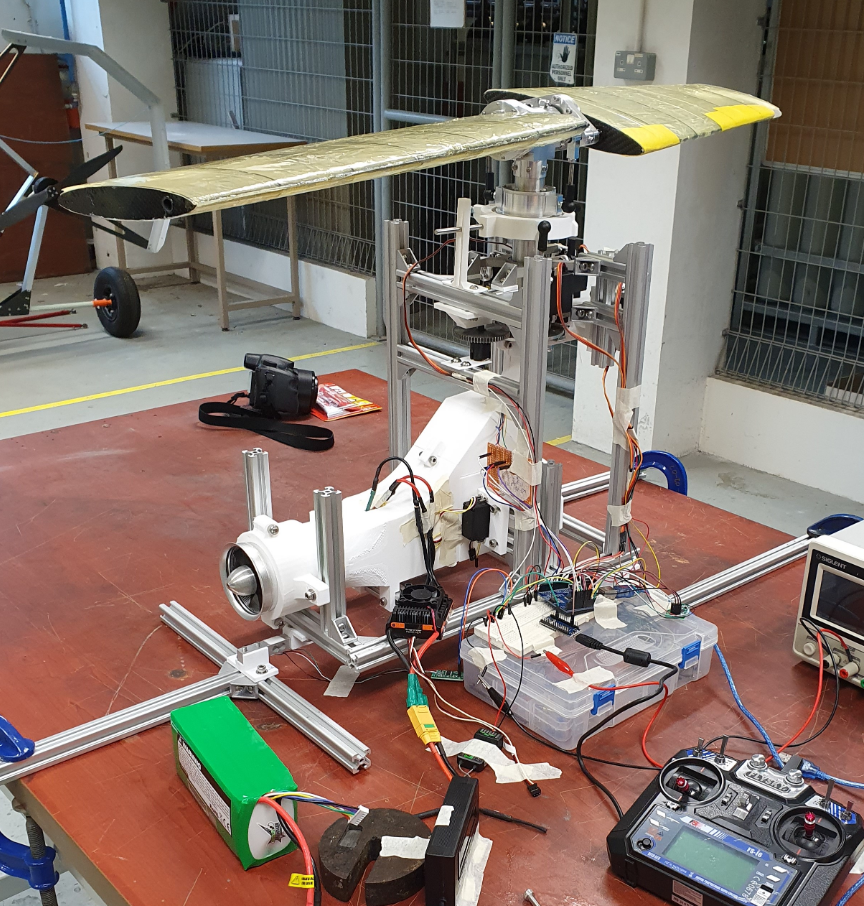

One such VTOL aircraft is the Canard Rotor Wing (CRW), which was tested in the early 2000s by Boeing. The original prototype featured a fuel-powered engine. However, fuel is considered a hazardous substance in drone regulations, hence, in this study, we designed and evaluated an electric-powered CRW aircraft instead, by using an electric ducted fan for the engine.

The CRW aircraft has two modes of flight, in fixed-wing mode and helicopter mode, with a transition phase in between. It features a tip-jet propelled rotor-wing that functions like a helicopter rotor in helicopter mode to provide lift. In fixed-wing mode, lift for the aircraft is provided by the forward canard wings and the horizontal tail.

Through our theoretical studies, we determined the amount of lift that the aircraft could generate in helicopter mode from the tip-jet rotor wing. Subsequently, we studied the transition process to understand the controls required in the aircraft for a successful transition. These theoretical studies showed that an electric-powered CRW aircraft was likely to be feasible. To verify the theoretical study, the CRW engine system was built and tested at various power settings.

Project Team

Student:

- Tse Qing Le Benjamin (Mechanical Engineering, Class of 2020)

Supervisors:

- A/Prof Lim Kah Bin (limkahbin@nus.edu.sg)

- Mr Brian Teo (teo.bs@nus.edu.sg)