CubeSat propulsion using additive manufacturing

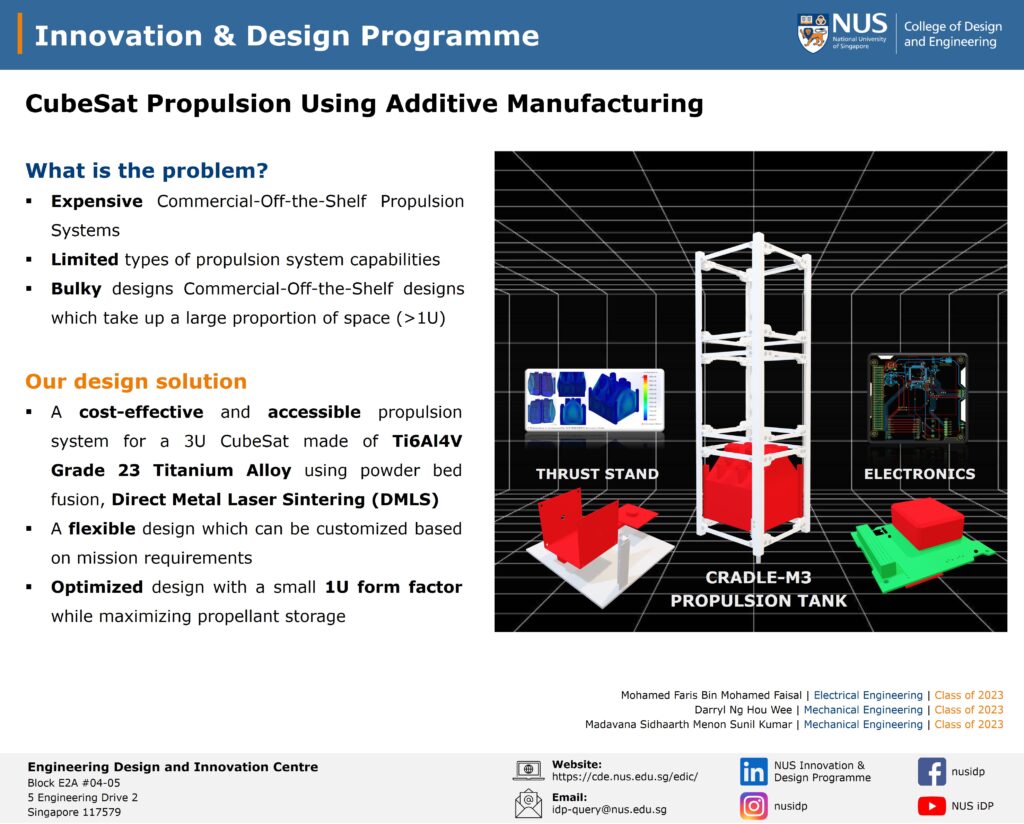

Commercial off-the-shelf propulsion systems for CubeSats are generally expensive and bulky. This limits their use by organisations who are interested to deploy CubeSats for research and non-commercial purposes. Moreover, they have limited capabilities and are difficult to tailor for specific missions.

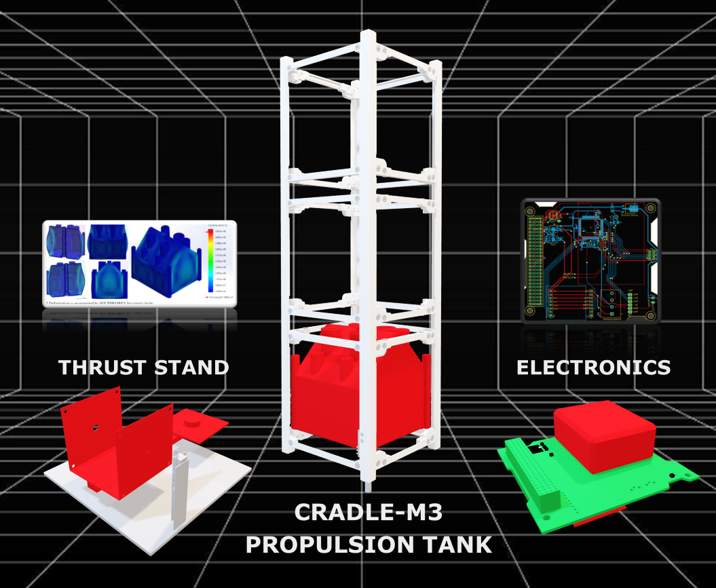

This project explores the use of additive manufacturing to produce a cost effective and accessible propulsion system for a 3U CubeSat. The propulsion system is made of Ti6Al4V Grade 23 titanium alloy, fabricated using powder bed fusion and direct metal laser sintering. It has a flexible design which can be customised based on mission requirements. The design is optimised with a small 1U form factor while maximising propellant storage.

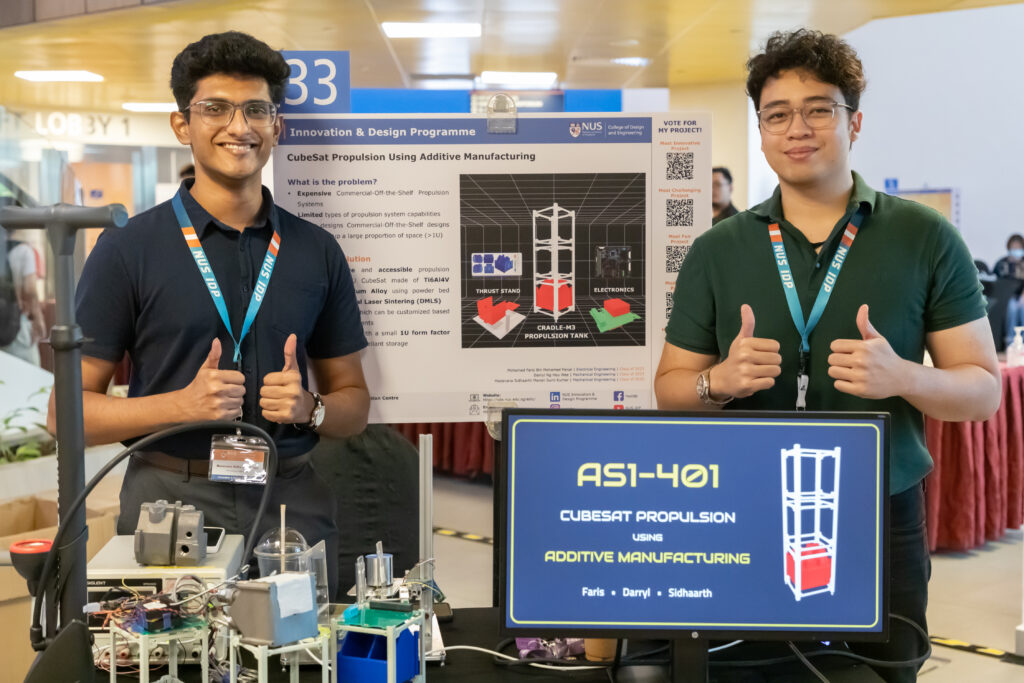

Project Team

Students:

- Darryl Ng Hou Wee (Mechanical Engineering, Class of 2023)

- Madavana Sidhaarth Menon Sunil Kumar (Mechanical Engineering, Class of 2023)

- Mohamed Faris Bin Mohamed Faisal (Electrical Engineering, Class of 2023)

Supervisors:

- Eugene Ee (wheee@nus.edu.sg)

- Soh Eng Keng (ek.soh@nus.edu.sg)