Imagine if swallowing a small low-cost pill or munching a cracker - both made from simple, natural plant fibre - could absorb all the saturated fat from a delicious burger.

A guilty pleasure would then carry a lot less weight, literally!

Well, that's the idea behind a breakthrough invention from researchers at the College of Design and Engineering, NUS (CDE) who have developed a way to upcycle waste pineapple leaves, a plentiful agricultural byproduct, into an edible fat-trapping material.

Pineapple production in South-East Asia and other parts of the tropics produces large amounts of waste - around three kilos of byproducts, much of it leaves - for every one kilo of fruit.

Most of this is usually discarded, burned or used as animal feed. Instead, the NUS research team led by Associate Professor Duong Hai-Minh (Dept of Mechanical Engineering) believe the waste leaves can be used much more profitably, with fat-trapping pills among a range of potential uses.

Photo gallery

Click thumbnails to view

Assoc Prof Duong got the idea whilst visiting his hometown in the Mekong Delta region of southern Vietnam, one of the world's major areas for pineapple production.

"Pineapple leaves are natural, biodegradable and biocompatible, as well as being very cheap and abundant," he said. "By exploiting the excellent mechanical properties of pineapple leaf fibres, our goal is to help reduce agricultural waste and increase farmers' profits."

Assoc Prof Duong's team has previously developed a way to turn pineapple fibres into a highly absorbent and high-value aerogel, which has applications such as cleaning up industrial oil spills.

Having seen this aerogel in action, Associate Professor Phan Toan Thang, from the Department of Surgery at the NUS Yong Loo Lin School of Medicine, suggested that the same principle could be applied to trapping fats in the human body.

"Everyone loves fatty food because it's so tasty!" said Associate Professor Phan. "But of course we also all know that saturated fats are very unhealthy and a major trigger for high blood pressure and other health conditions. Our new material absorbs the fatty compounds and forms fat-coated fibre lumps, which are then passed out from the digestive system in one to three days, similar to other foods we consume."

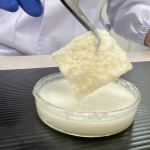

The process for making the fat-trapping material makes use of the high cellulose content found in pineapple leaves. By developing a cost-effective way to extract and treat the leaf cellulose, the team has produced a patented material that applies the leaves' mechanical properties to the absorption of saturated fats.

The cellulose is extracted, dried and processed, before being mixed with an edible compound commonly already used in many health supplements that allows the fibre to maintain its structure whilst passing through the acidic environment of the human stomach.

In laboratory tests, the researchers found that one gram of their finished pineapple leaf material can absorb up to 45 grams of saturated fats - around twice as much as in a standard burger.

Working together with Prof Duong, Prof Phan and the NUS research team have developed and patented the fat trapping material into both a capsule and a small cracker.

With waste pineapple leaves in abundance, they say the product is easy to scale with production costs working out well below 10 cents per pill, significantly undercutting currently available fat trapping supplements on the market.

The team are now seeking partners to help commercialise the technology.