![Photo 2[77] The researchers used a 3D bioprinter to fabricate customised oral soft tissue grafts, integrating AI into the process, to optimise bioprinting parameters, enhance precision, and boost efficiency.](http://cde.nus.edu.sg/wp-content/uploads/2025/04/Photo-277.png)

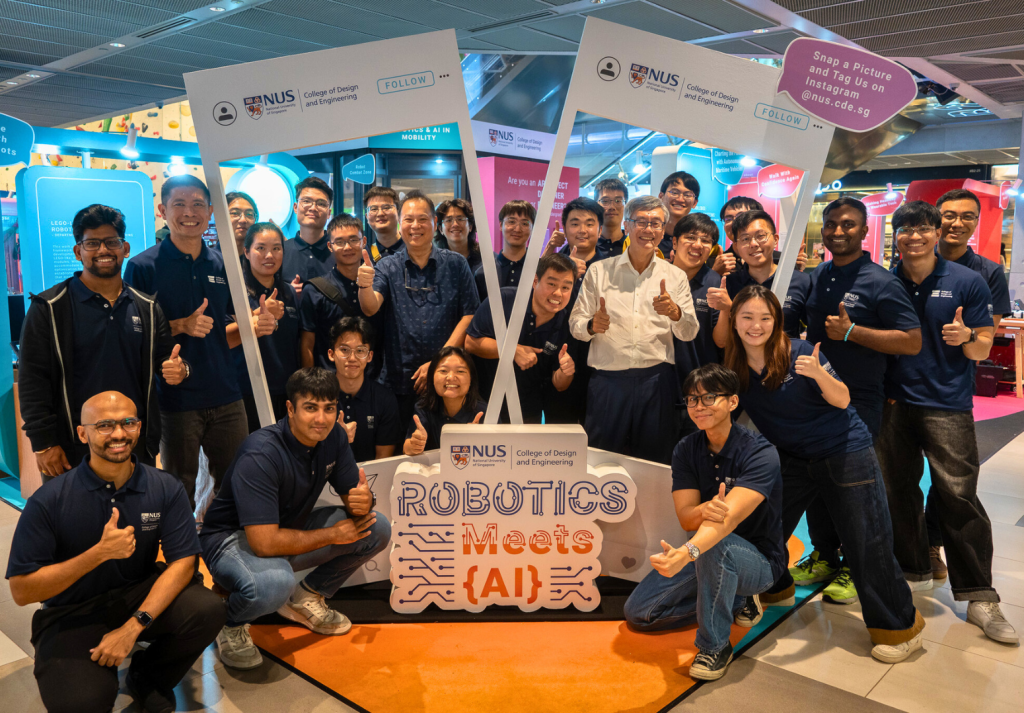

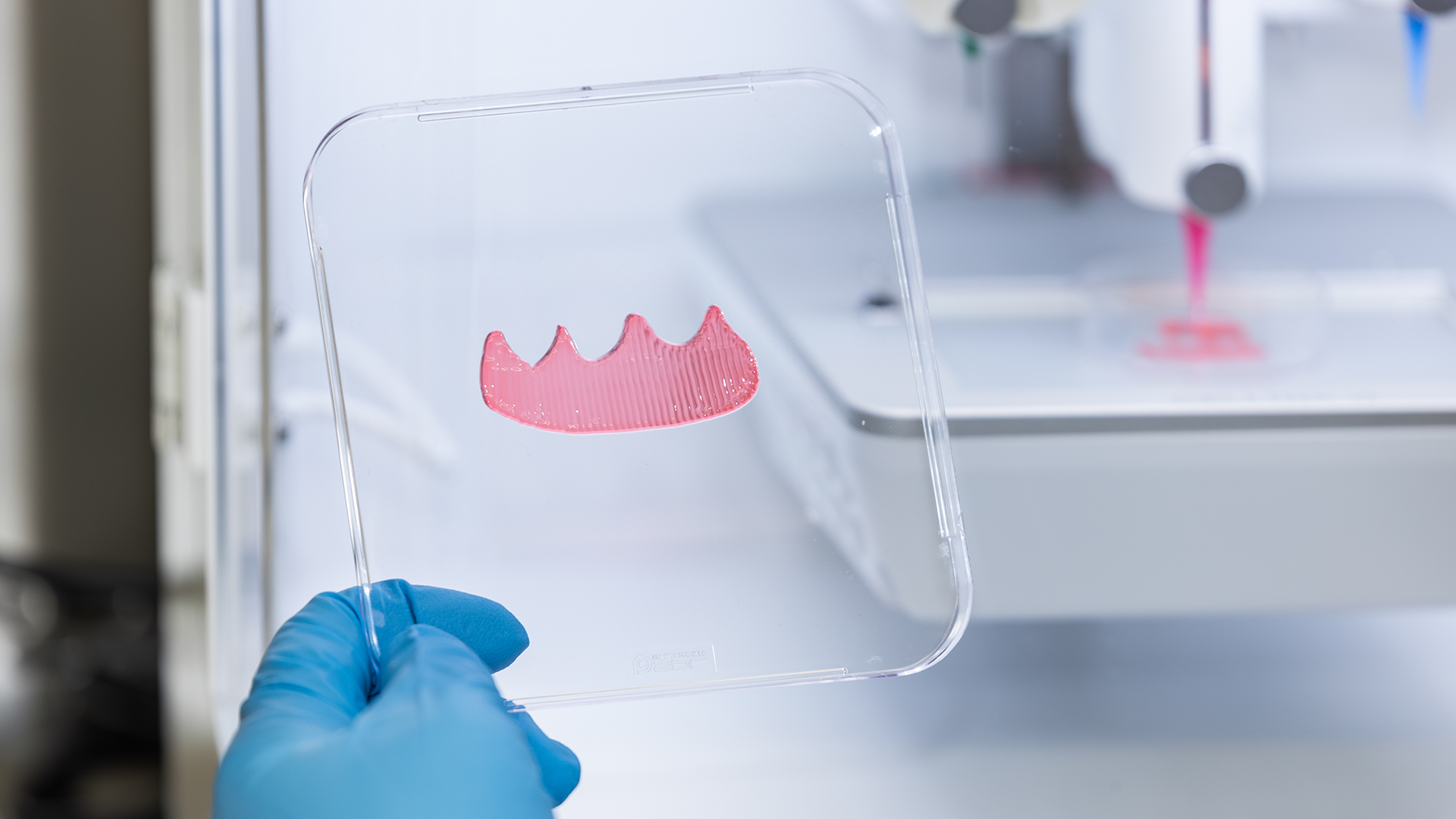

An AI-powered method to speed up the 3D bioprinting of personalised gum tissue grafts promises to significantly improve efficiency and precision in regenerative dentistry, reducing the need for painful tissue harvesting from patients.

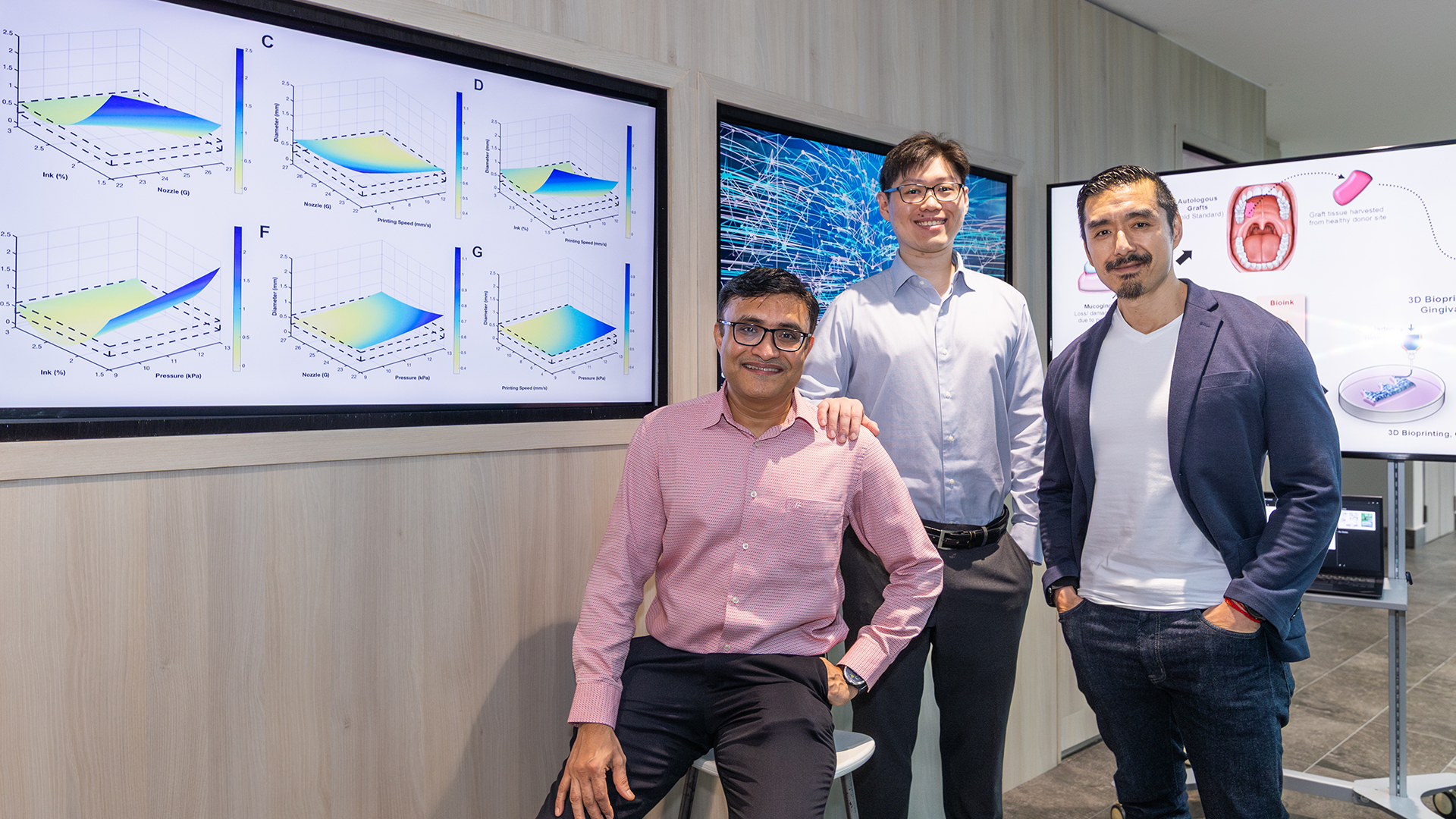

The innovative approach is the result of research jointly led by researchers from CDE under Professor Dean Ho (Biomedical Engineering) and the NUS Faculty of Dentistry. The team’s breakthrough addresses key challenges in traditional methods of gum grafting, which often requires harvesting tissue from a patient’s mouth—a process that can be painful and constrained by tissue availability.

Prof Ho, Head of the Department of Biomedical Engineering and co-corresponding author of the study, said: “We used AI to refine the bio-ink formulation developed by the research team at Dentistry, making it more effective for creating soft tissue grafts. This has broad applications in dental treatments, including implants and gum disease.”

He added: “By incorporating AI, we were able to greatly streamline the process, reducing the number of experiments needed to optimise the bioprinting parameters from potentially thousands to just 25 combinations. This efficiency boost ensures the production of precise, biomimetic gum tissue grafts while cutting down the extensive trial-and-error process typically required in bioprinting.”

Dr Peter Wang and Dr Kui You from Biomedical Engineering co-designed the AI-driven bioprinting optimisation process. At the time both were PhD students and are now Research Fellows in the department.

“Dr You and I carefully designed the bioprinting optimisation experiment, assessing how different print parameters interact,” said Dr Wang. “We provided a list of 25 carefully selected print parameter combinations to the team at Dentistry, who tested them and measured the resulting print diameters. Using this data, we applied an AI-driven optimisation platform to analyse parameter interactions and identify the best combinations for achieving the desired print diameter.”

Dr Wang said the AI platform helped identify the best printing settings to produce grafts within the ideal size range. This level of customisation, he added, could make dental treatments like implants more effective and less invasive.

The AI-driven approach rapidly identifies optimal parameters by analysing multiple variables at once, significantly reducing the time and resources needed for fine-tuning while ensuring consistent quality in printed grafts. The resulting constructs closely resemble natural gum tissue, maintaining over 90% cell viability and exhibiting key biological properties essential for successful implantation.

Beyond dental applications, the researchers say the AI-enhanced bioprinting technique could be adapted for other medical fields, such as skin grafts for scarless wound healing.

Going forward, the team plans to conduct in vivo studies to assess the stability of the grafts in real-world conditions and explore multi-material bioprinting to incorporate blood vessels, further advancing the field of regenerative medicine.

The research, jointly led by Assistant Professor Gopu Sriram from the NUS Faculty of Dentistry, was published in the journal Advanced Healthcare Materials.

For more details see the NUS Press Release.