An innovative RNA-based biosensor that can detect flavonoids with exceptional precision could significantly accelerate the development of microorganisms that can produce the valuable but hard-to-produce natural compounds, widely recognised for their health benefits.

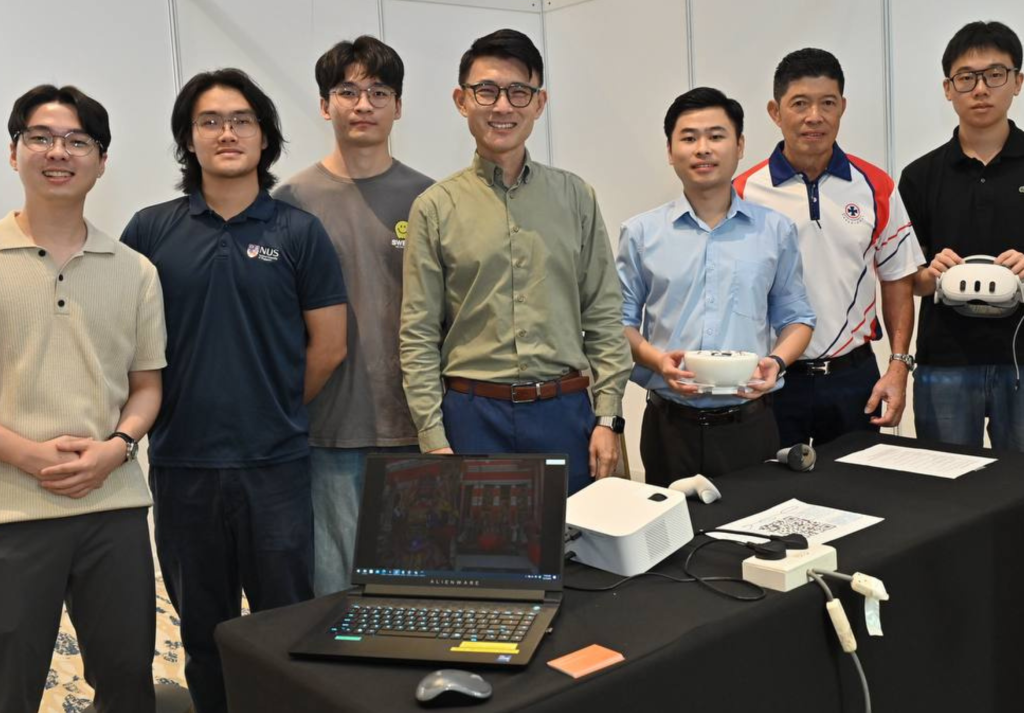

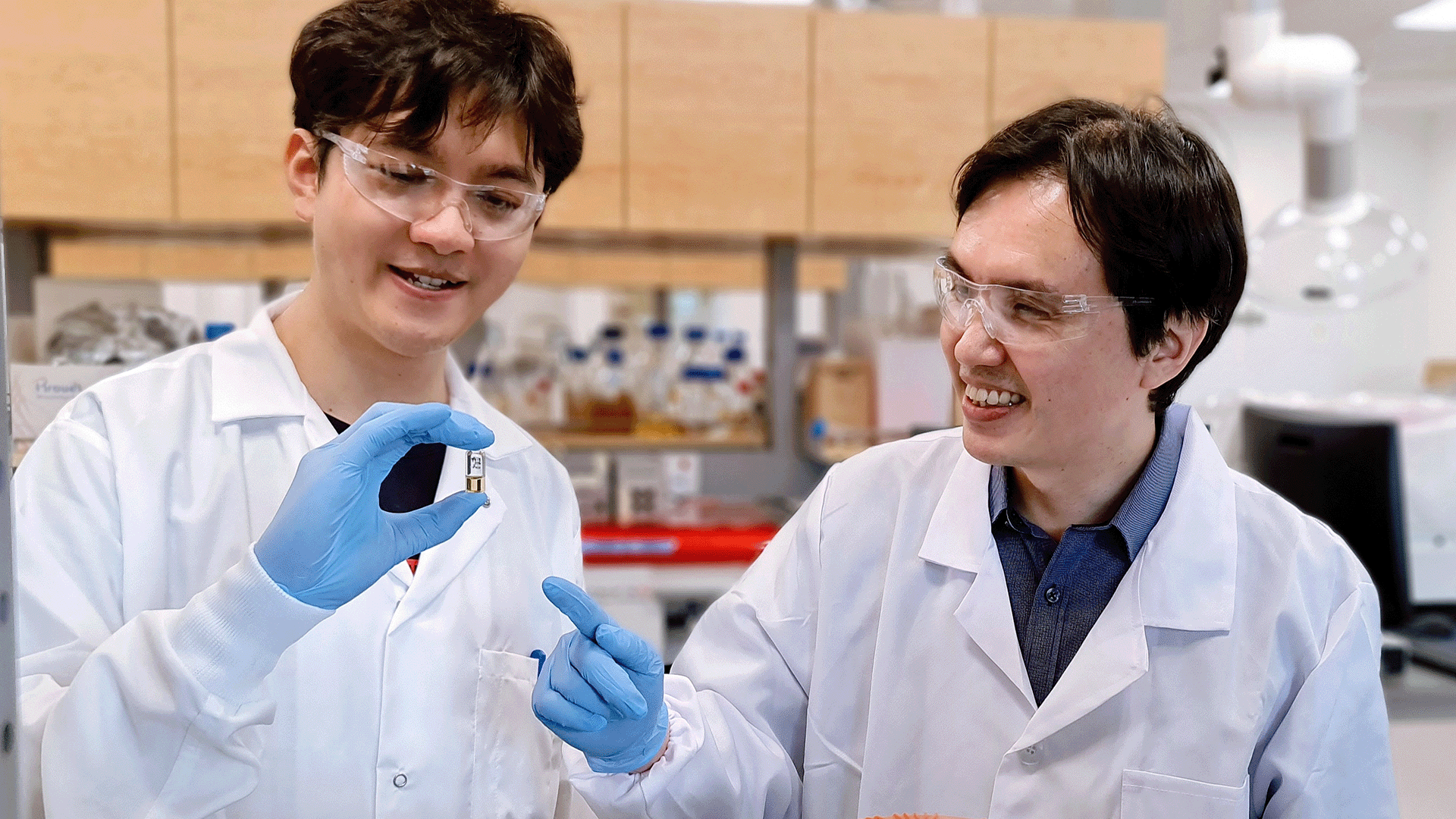

The sensor, developed by a team of researchers at CDE led by Associate Professor Poh Chueh Loo (Biomedical Engineering) and Research Fellow Dr Zhang Jingyun (Biomedical Engineering), has been shown to increase the throughput of sample screening by 10,000 times compared to current methods. In April, the team received the Gold Medal at the International Exhibition of Inventions held in Geneva, Switzerland.

Flavonoids are a family of powerful compounds found in fruits and vegetables that act as antioxidants, helping fight cancer, reduce inflammation, and protect the cardiovascular system. These compounds are increasingly used in various industries, including nutraceuticals, pharmaceuticals and cosmetics, with the global flavonoids market expected to reach US$1.65 billion by 2029.

“Traditionally, flavonoids are extracted from plants, but the process is unreliable, inefficient and unsustainable,” said Assoc Prof Poh. “For instance, only a tiny fraction of a gram of flavonoids can be extracted from a kilogramme of fruit, which means a lot of land is used for a very small amount of product. Furthermore, as climate change presents additional challenges to crop growth, there's a growing need for more reliable and sustainable methods of flavonoid extraction.”

Engineering microorganisms to produce flavonoids has been seen as a promising alternative, but finding the right microorganisms that are the high producers is slow and costly. Current methods, like High-Performance Liquid Chromatography (HPLC), can process only about 100 samples per day. In contrast, the researchers say, the RNA-based biosensor enabled method can process around one million samples in the same timeframe, with results delivered in real-time.

“What’s needed is a quick efficient way to screen for the high producers, without having to do all the tedious sample preparations and with a much higher throughput,” said Assoc Prof Poh.

The research team’s solution to this challenge uses sequences of ribonucleic acid (RNA) - a molecule that plays a crucial role in coding, decoding, regulating, and expressing genes - to create tiny sensors that can detect specific compounds within cells.

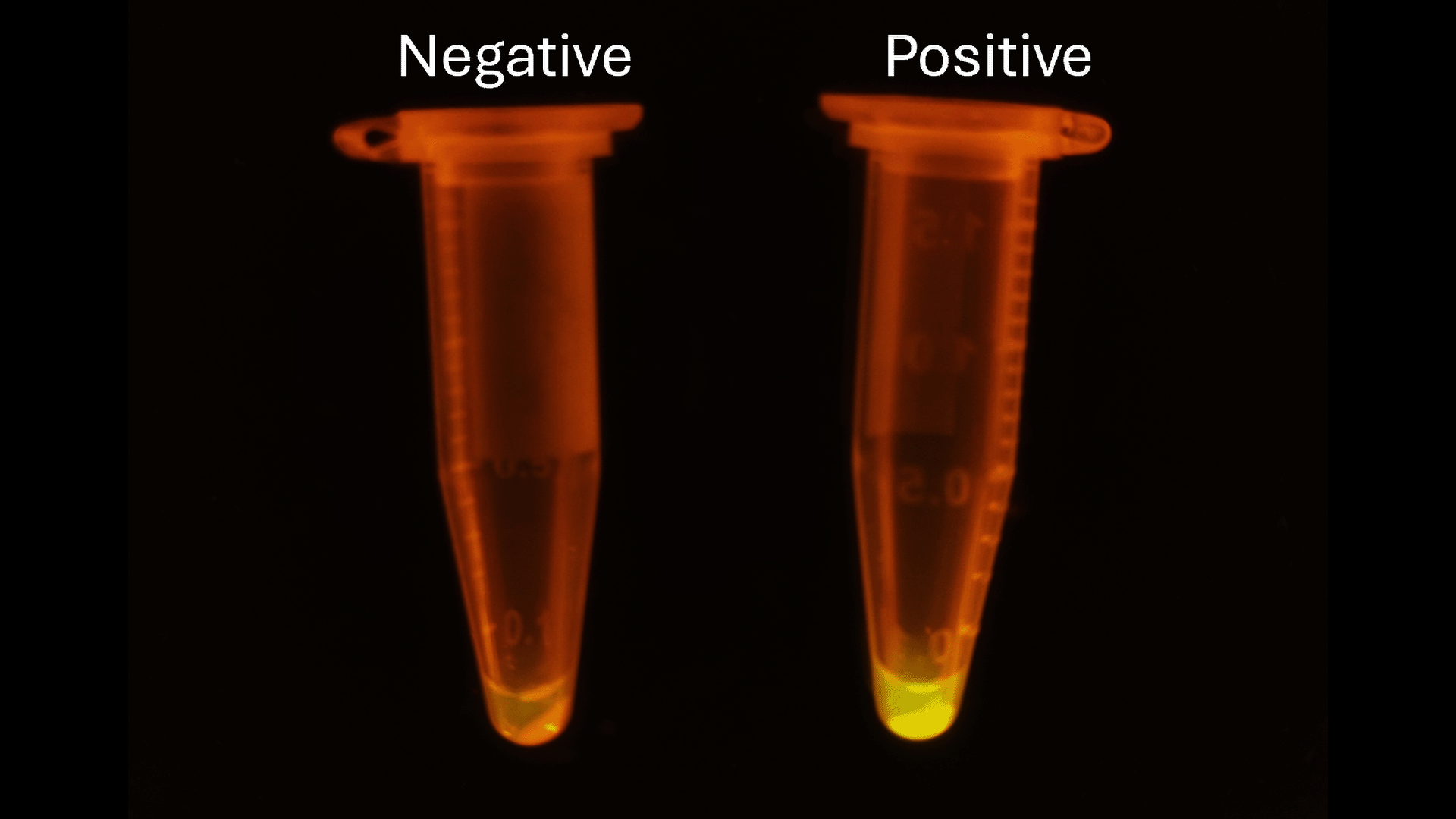

“When the biosensors detect flavonoids, they emit a fluorescent signal, making it easy to visually identify which microorganisms are producing high amounts of the compound,” said Assoc Prof Poh. “This allows for rapid and precise screening, combined with high levels of accuracy and sensitivity.”

Compared to conventional screening methods, he said, the biosensors offer several advantages:

- Efficiency: The biosensors enable real-time, in-cell detection without the need for extensive sample preparation.

- Speed: The biosensors can process results in milliseconds, whereas HPLC takes several minutes per sample.

- Cost-Effectiveness: Each test using the biosensors costs a small fraction of a cent compared to a few dollars for a single HPLC test, in addition to the human labour involved.

- High Throughput: The screening method enabled by the biosensors can potentially screen over one million samples per day, a 10,000-fold increase over traditional methods.

- Miniaturisation: The biosensors require minimal reagents – measured in microliters compared to the millilitres needed for HPLC.

With the biosensor enabling the detection of flavonoids more quickly, more efficiently, and more cost-effectively, the researchers say their invention could revolutionise sectors of the healthcare, nutrition and well-being industries which use flavonoids as supplements or ingredients in their products. Additionally, they say, the biosensors can also be used to engineer flavonoid-producing microbes, leading to a more sustainable production of flavonoids.