“Stay curious, be bold, and keep building,” said Er Chan Ewe Jin, President of the Institute of Engineers Singapore (IES), at the Engineering Innovation Challenge (EIC) prize ceremony. “Engineering is not just about mastering technical knowledge. It’s about using that knowledge to solve real problems, improve lives, and create a better future for all,” he added.

Organised annually by IES as part of National Engineers Day, the EIC is a national competition that encourages students to tackle real-world issues through engineering innovation. This year, nearly 180 student teams competed across four categories: Secondary School, Junior College, ITE & Polytechnic, and University. The prize ceremony was graced by the Guest of Honour, Ms Sun Xue Ling, Senior Minister of State for National Development and Transport.

With the theme “Shaping the Future with Engineering Innovation,” students were challenged to develop solutions for resilient city living in areas such as Renewable Energy and Materials, Digital Transformation, Health Innovation, and the Food Supply Chain.

CDE teams brought home the Category 4 (University) Champion title and four Merit Awards out of 20 competing university teams! Two teams included students from the College of Humanities and Sciences (Physics) and NUS Business School.

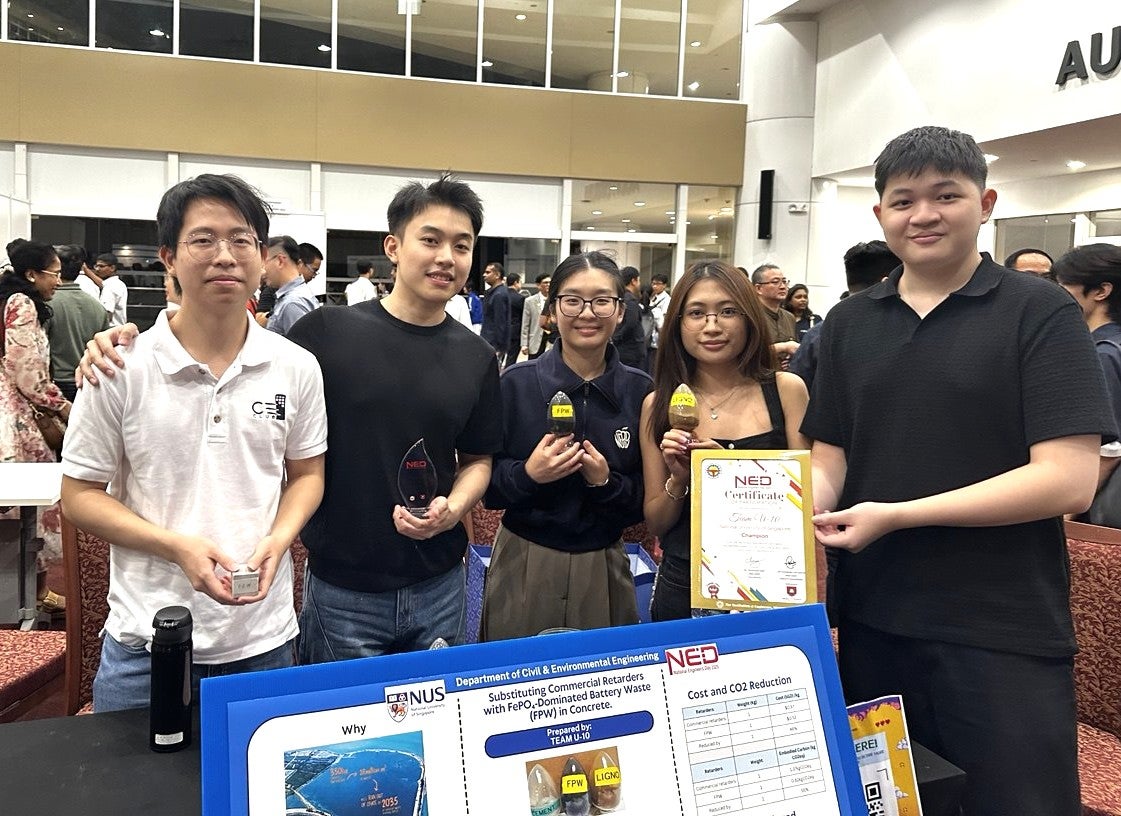

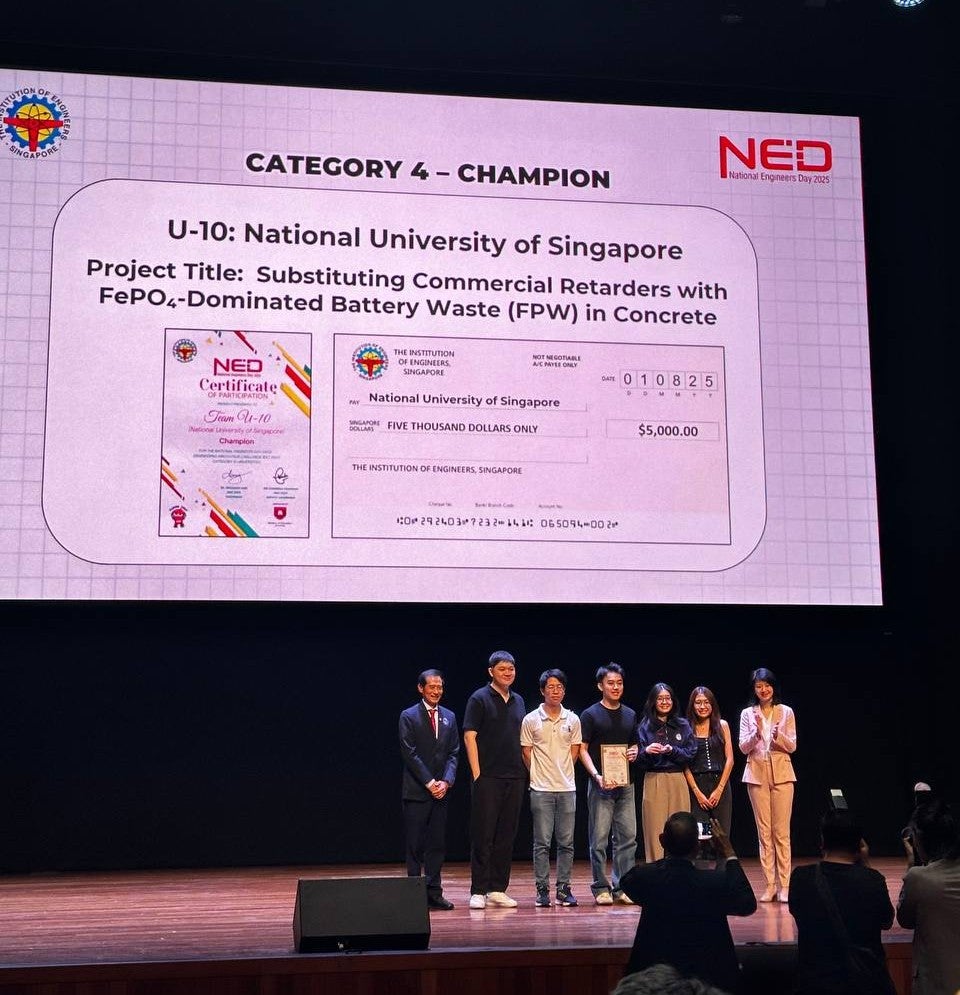

Tan Tin Chong, Quay Genk Swee Daniel, Shermaine Kong, Su Rati Naing, and Theikhar Maung from Civil Engineering clinched the Champion title with their project “Substituting commercial retarders with FePO₄-Dominated Battery Waste (FPW) in concrete.”

Supervised by Dr Du Hongjian and co-mentored by Dr Luo Zhiyu, both from the Department of Civil and Environmental Engineering, the team explored how iron phosphate waste (FPW), recovered from spent electric vehicle batteries, could be repurposed as a sustainable concrete admixture.

By replacing conventional chemical retarders with three per cent FPW by cement weight, they successfully delayed setting times while maintaining compressive strength. The project presents a practical way to upcycle battery waste, reduce reliance on imported additives, and support Singapore’s circular economy and zero-waste goals.

“Each concrete sample took 28 days to fully cure, which meant we had limited chances to identify the optimal mix ratios,” said the team. “Despite the time crunch, we’re proud to have developed a viable green solution with the guidance of Dr Du and Dr Luo. We hope to scale our trials for real-world use and promote recycled battery materials in construction to support a greener future.”

Dr Du said, “This achievement reflects our students’ strong competency in solving complex problems. Their passion for building a sustainable society translated into real action and innovation. Through this challenge, they demonstrated how engineering can drive impactful solutions in waste upcycling.”

Team Members

- Tan Tin Chong (Year 3, Civil Engineering)

- Quay Genk Swee Daniel (Year 3, Civil Engineering)

- Shermaine Kong (Year 3, Civil Engineering)

- Su Rati Naing (Year 3, Civil Engineering)

- Theikhar Maung (Year 3, Civil Engineering)

Co-mentor

Dr Luo Zhiyu (Research Fellow, Department of Civil and Environmental Engineering)

Supervisor

Dr Du Hongjian (Senior Lecturer, Department of Civil and Environmental Engineering)

In addition to the Champion title, four other CDE teams received Merit Awards:

1. Sustainable Superabsorbent – cellulose-based hydrogels for a green and sustainable agriculture

To address the growing challenges in global food production, such as climate change, population growth, and resource scarcity, the team developed green hydrogels made from natural materials like cellulose and citric acid. These hydrogels are designed to retain water and nutrients in soil, helping crops grow more efficiently in dry conditions.

What sets this project apart is its focus on testing how these eco-friendly hydrogels directly impact plant growth, offering a practical step towards more sustainable and affordable farming. It began as an individual undergraduate research project by Chia Min Shen under the Undergraduate Research Experience (UREx) programme and grew into a team effort with support from Assistant Professor Iris Yu. Min Shen said, “This project gave us a new lens to view the circular economy loop and bioresources upcycling." As the team progressed, they identified research gaps they hope to explore further, including investigating the cross-linking mechanisms behind hydrogel formation to improve its performance.

Team Members

- Chia Min Shen (Year 3, Environmental Engineering)

- Tong Zheng Yin (Year 2, Chemical Engineering)

- Reiner Putra Indrayanto (Year 3, Environmental Engineering)

- Nathania Frida (Year 3, Environmental Engineering)

Supervisor

Assistant Professor Iris Yu (Department of Civil and Environmental Engineering)

2. Conceptualising and testing of reinforcement insertion method(s) on 3D concrete printing for Prefabricated Prefinished Volumetric Construction (PPVC)

This project aims to improve 3D concrete printing for high-rise modular buildings by simplifying the insertion of steel reinforcements. While modular construction using Prefabricated Prefinished Volumetric Construction (PPVC) allows building parts to be made off-site, it still relies on time-consuming and wasteful moulds. 3D concrete printing could replace these moulds with permanent, automated ones, but adding steel bars into the printed structures remains tricky. This project focused on designing an automated system, using either a robotic arm or a gantry, to insert the bars during and after the printing process. The aim is to make construction faster, more precise, and more sustainable.

Looking ahead, Justin Adrian Halim plans to develop further his award-winning project, which addresses a specific aspect within a larger research effort led by Ng Jun Liang Ben (PhD candidate, Department of Civil and Environmental Engineering). While the submission was independently developed, it contributes to the team’s broader goal of making 3D Concrete Printing (3DCP) viable for Prefabricated Prefinished Volumetric Construction (PPVC). Justin’s goal is to eventually design a full 3DCP PPVC module and develop a suite of automated robots capable of fabricating the entire system with security, precision, and reliability, making construction faster, more accurate and sustainable.

Project by

Justin Adrian Halim (Year 3 Civil Engineering, Second Major in Computing)

Supervisor

Dr Du Hongjian (Senior Lecturer, Department of Civil and Environmental Engineering)

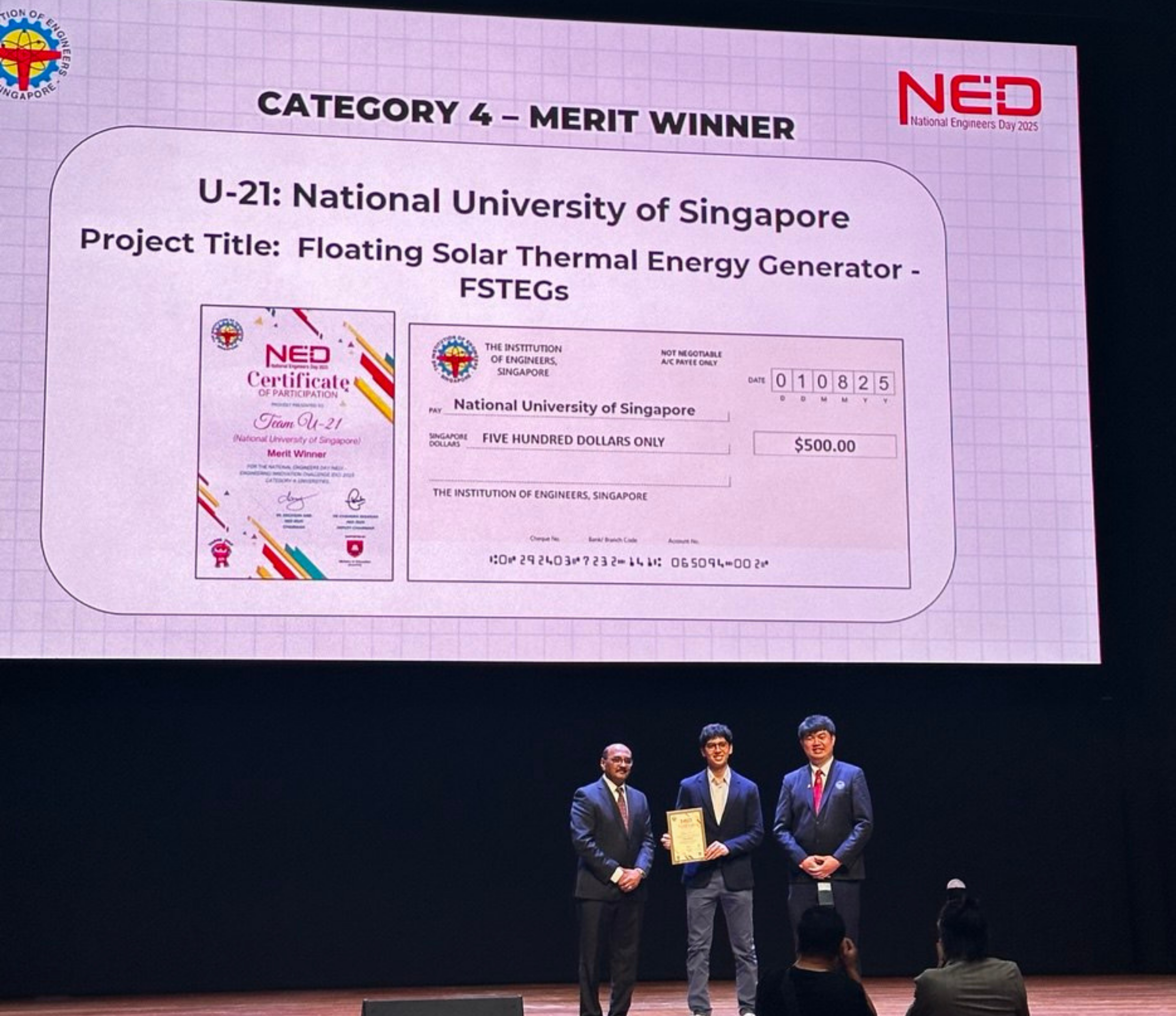

3. Floating Solar Thermal Energy Generator – FSTEGs

This project introduces a floating solar thermal energy generator (FSTEG) that converts sunlight into electricity using heat rather than conventional solar panels. Designed to float on water bodies, the device uses a special lens to focus sunlight and generate heat, which is then converted into power using the temperature difference between the heated surface and the cooler water beneath.

This approach produces up to 670W per square metre, three times more than traditional solar panels, at just two-thirds the cost. Its modular and recyclable design is easy to scale and fits well with infrastructure near water, such as data centres and reservoirs. FSTEG offers a sustainable energy solution for regions with limited land but abundant water, including coastal cities, islands, and densely populated countries.

Team members

- Sparsh (Year 4 Computer Engineering, Second Major in Innovation and Design Programme)

- Azann Qureshi (Year 3 Physics)

Supervisor

Dr Ang Yu Qian (Postdoctoral Fellow, Department of Built Environment)

4. ClearPlate: AI-Driven food waste detection at RC4 Dining Hall and beyond

ClearPlate is an AI-powered system designed to help reduce food waste. By simply taking a photo of a dining hall plate, the system analyses and estimates the amount and type of leftover food. Tailored for large dining halls where menus and food presentations change frequently, it delivers real-time feedback to both diners and food suppliers, encouraging more mindful consumption.

“One of our main challenges was ensuring the system’s accuracy despite constantly changing menus,” shared team member Ng Jun Wei. To address this, the team built a rapid-training pipeline using advanced segmentation models and monocular 3D reconstruction techniques. This allowed ClearPlate to quickly label new food items and retrain detection models, enabling it to adapt to dynamic dining environments.

Dr Jovan Tan, the team’s supervisor from the Engineering Design and Innovation Centre, said, “ClearPlate encourages more conscientious eating through a simple photograph and plays a meaningful role in accelerating NUS’s efforts towards a more sustainable campus.”

Team members

Ng Jun Wei (Civil Engineering ’25, Year 1 Master of Science in Business Analytics, Engineering Scholar)

Ryan Tan Yang Yong (Year 4 NUS Business School and Business Analytics double degree)

Teo Jia Xin (Year 4 Environmental Engineering and Economics double degree, Engineering Scholar)

Han Yan Chou, Don (Year 2 NUS Business School and Communications and New Media double degree)

Supervisor

Dr Jovan Tan (Lecturer, Engineering Design and Innovation Centre)