A new material for capturing carbon dioxide (CO2) discovered by researchers at CDE could be a significant step forward in reducing emissions and mitigating global warming.

The researchers say it also has the potential to deliver a financial payback by creating the basis for producing commercial chemicals from the captured gas.

This would make the process of capturing emissions not only beneficial to the environment, but create an economic benefit as well.

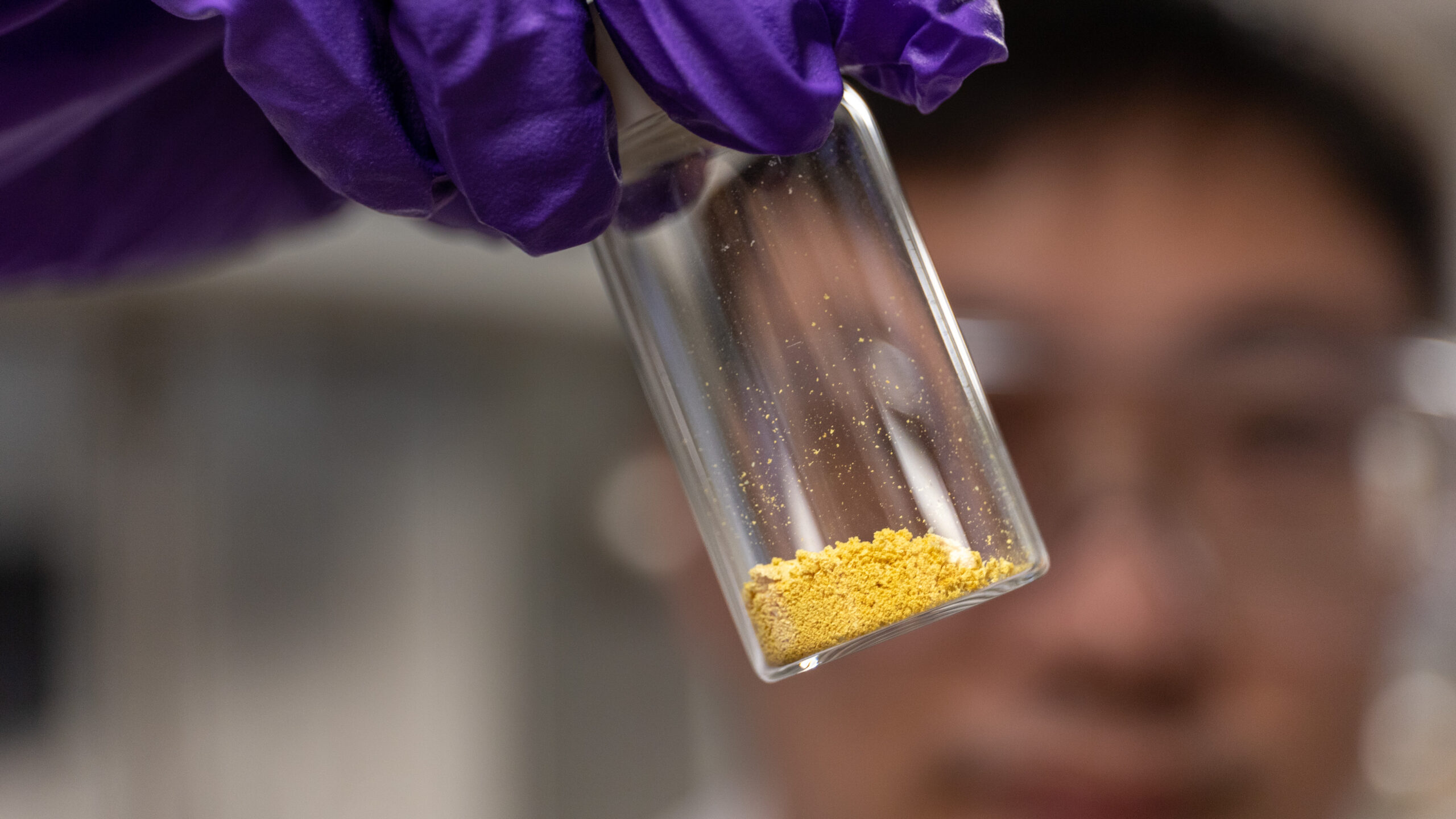

The mechanism is based on a new type of porous polymer material known as a covalent organic framework (COF) that has been treated with metal ions. This gives the treated COF the ability to capture and retain far higher levels of CO2 compared to other materials currently used for carbon capture.

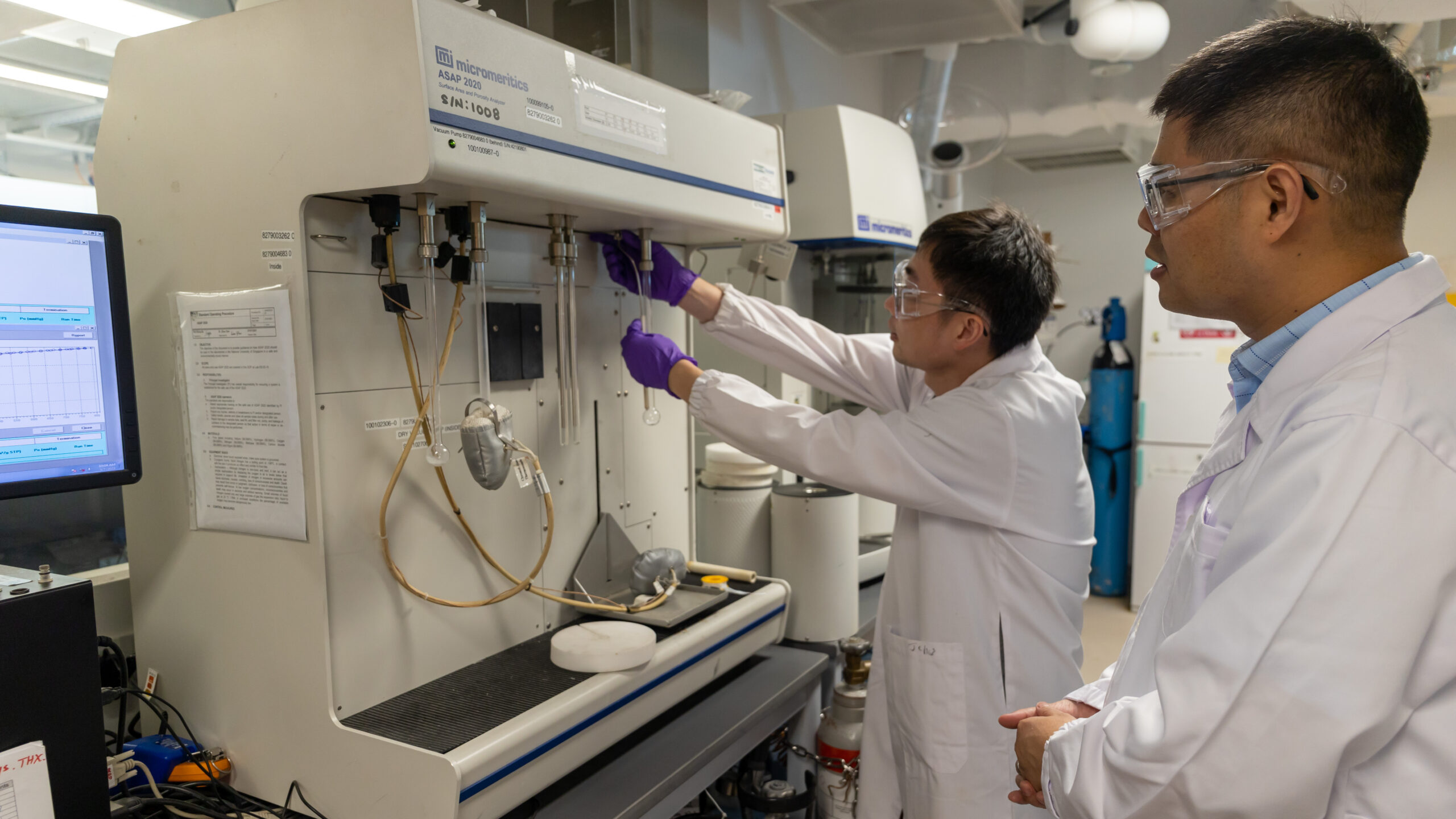

The material was developed by a research team at CDE led by Associate Professor Zhao Dan (Department of Chemical and Biomolecular Engineering).

The team’s findings were reported recently in the scientific journal PNAS, published by the National Academy of Sciences in the US.

COFs made from various materials are a relatively recent invention that have attracted growing scientific interest because their highly porous crystalline structure makes them useful for applications such as gas storage and catalysis.

They can also be designed to have very specific pore sizes and shapes, which makes them useful for gas separation — an essential property in capturing CO2 efficiently from emission sources such as power plants.

The new COF material developed by Assoc. Prof. Zhao works by capturing CO2 molecules via insertion between metal ions and nitrogen atoms on its surface.

A particular benefit of the new material with regard to CO2 capture applications is the high selectivity it implies in the unique CO2 capture mechanism, especially when compared to other gas filtering materials in use.

“What this means,” said Assoc. Prof. Zhao, “is the degree of ‘pickiness’ the material shows in extracting one gas from a combination of gases, such as what we see in the mixture of emissions coming out of the flue systems of power stations”.

In such scenarios, whilst the amount of CO2 emitted by power plants is large, the proportion of CO2 in the overall emissions each plant generates is relatively low, typically varying from around 4 to 15% of total emissions.

This has proven a problem for other filter materials, which can extract CO2 at high concentrations but struggle to work effectively when the concentrations are low.

In the case of the new COF material, however, the strong attraction of the nitrogen and ion atoms on the CO2 molecules makes it act like a magnet for the gas.

“With this new COF material, we found a very interesting mechanism,” said Assoc. Prof. Zhao.

“CO2 is drawn into the material, and it gets grabbed by two atoms – one is nitrogen, one is metal — so that the CO2 becomes activated. With molecules, if you grab them just by one force, the molecule is adsorbed onto the material; but if you grab it by two types of force, you elongate the molecule, and the molecular bond gets weakened.”

This weakening of the molecular bond, he said, opens up the possibility of converting the adsorbed CO2 into other gases used to make chemicals that could then be sold, creating a commercial product from what is typically seen as a “waste” gas.

“When developing carbon capture technology, there’s always the question of what are you going to do with the captured CO2?” said Assoc. Prof. Zhao.

“The problem is that CO2 is a very stable molecule with very strong bonds — normally you need high temperature, high pressure, or other energy-intensive methods to activate it, all of which are expensive. But in the case of this new material, with the CO2 adsorbed onto the COF’s surface by nitrogen and ion atoms, it becomes activated, and the bond weakened.”

Assoc. Prof. Zhao said this “creates the exciting potential that CO2 is not only captured by the COF material, but it is activated and ready to be converted”.

“This work was supported by A*STAR Low-Carbon Energy Research Funding Initiative (LCER FI) under the project “Adsorptive Carbon Capture Using Framework Materials” and in collaboration with ExxonMobil under the auspices of the Singapore Energy Centre.”