A new vapour-deposition method dramatically improves the long-term and high-temperature stability of perovskite-silicon (Si) tandem solar cells. The approach, developed by researchers at CDE, could help overcome key durability and manufacturing barriers for tandem solar cells that have limited their real-world deployment.

Tandem solar cells combine two light-absorbing materials to capture more of the solar spectrum than conventional silicon solar cells, allowing significantly higher power conversion efficiencies from the same surface area. The breakthrough marks the first time vapour deposition has been successfully applied to industrial micrometre-textured silicon wafers, the actual wafer structure used in commercial solar cell manufacturing, marking a major milestone for translating laboratory-scale tandem solar cells into real-world products.

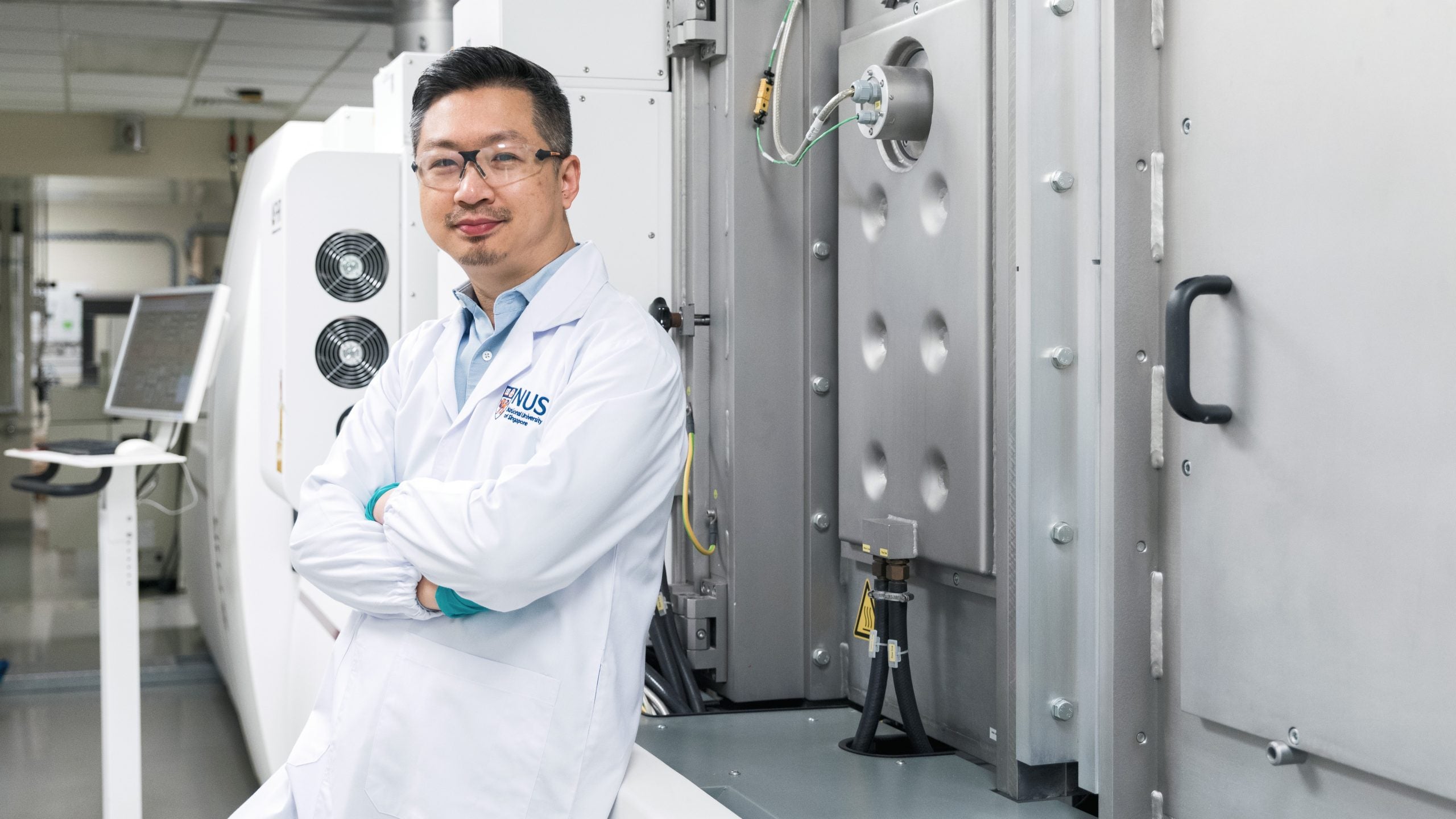

The research was led by Assistant Professor Hou Yi, Presidential Young Professor in the Department of Chemical and Biomolecular Engineering under CDE, and Head of the Perovskite-based Multijunction Solar Cells Group at the Solar Energy Research Institute of Singapore (SERIS) at NUS.

The findings were published in Science on 19 December 2025.

The new method enables conformal, high-quality perovskite growth on industrial micrometre-scale textured silicon wafers, a critical requirement for mass production. It also delivers more than 31 per cent power-conversion efficiency with operational stability far exceeding 2,000 hours, including T90 lifetimes, the time taken for performance to drop to 90 per cent of initial output, of over 1,400 hours at 85 deg C under 1-sun illumination, a standard benchmark in solar energy representing a light intensity of 1000 watts per square metre.

These results represent one of the most durable perovskite-Si tandem solar cells ever reported, validating a viable pathway toward commercial photovoltaic modules.

Long-lasting solar cells

For tandem solar cells to be deployed on rooftops, solar farms, and industrial facilities, they must endure years of high temperatures, humidity, and intense sunlight. Achieving such long-term durability on industrial textured silicon wafers, rather than on specialised laboratory surfaces, is essential for commercial manufacturing.

“Achieving both high efficiency and long-term durability on industrial textured silicon is essential for tandems to become commercially viable,” said Asst Prof Hou.

Although vapour deposition has long been viewed as a scalable and industry-friendly approach, it had never successfully produced stable, high-quality perovskite layers on true industrial silicon with large textures. By accomplishing this for the first time, the Asst Prof Hou’s team has overcome a major manufacturing barrier and demonstrated a level of high-temperature stability needed for future deployment.

A new molecular strategy

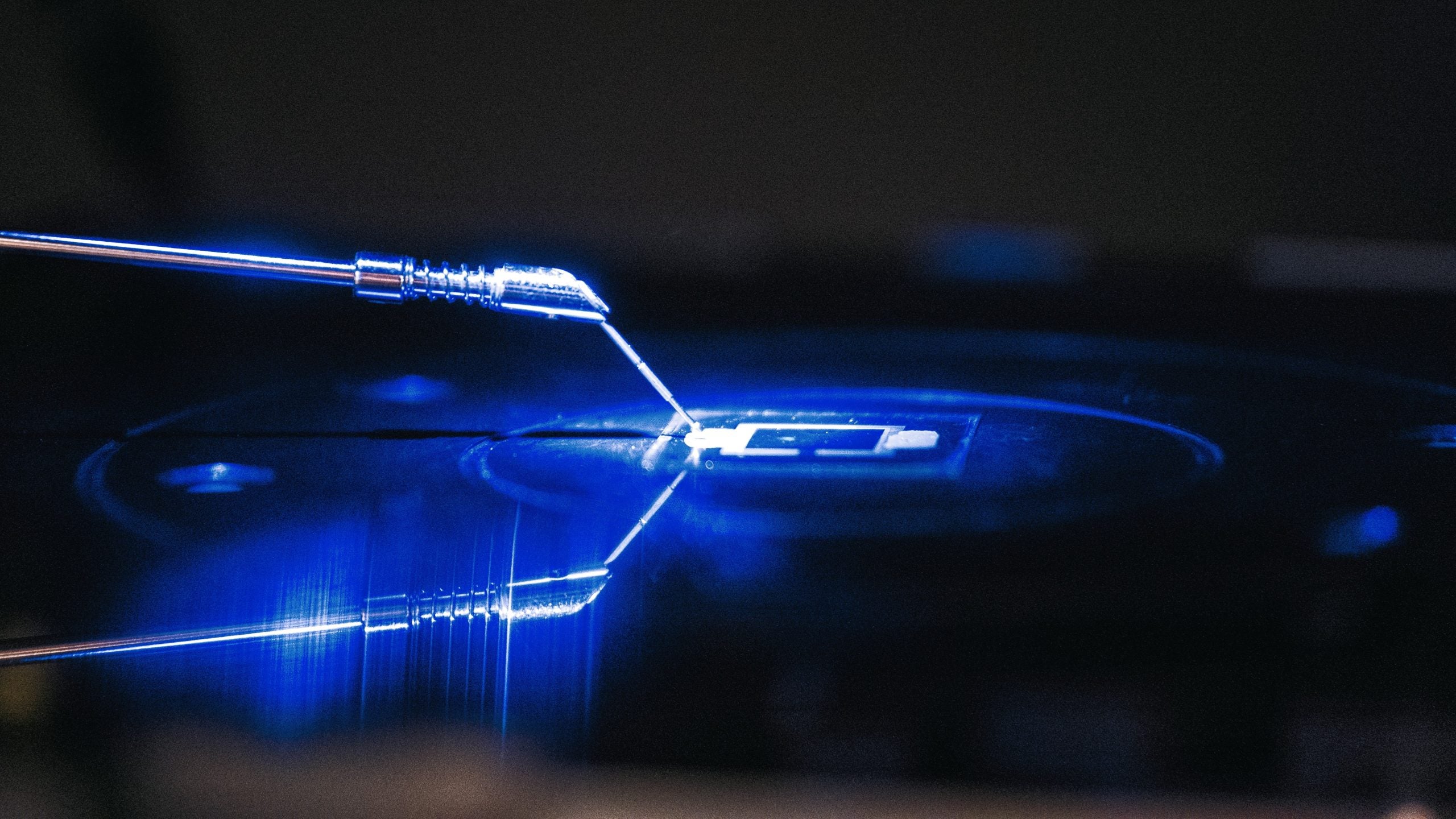

During vapour deposition, organic perovskite precursor molecules struggle to adsorb uniformly onto the steep pyramid textures that define industrial silicon wafers. This imbalance leads to poor film formation and rapid degradation under heat.

To resolve this, the researchers designed a specialised molecule that binds to the silicon surface and enhances the adsorption of organic molecules during vapour deposition, allowing the perovskite film to grow smoothly with the correct chemical balance.

As a result, the vapour-deposited tandem devices displayed exceptional thermal endurance. They sustained stable operation for well over 1,000 hours under continuous illumination and maintained strong performance during extended exposure at 85 deg C, one of the most demanding ageing tests in the solar industry.

Achieving such high-temperature stability in perovskite-based tandems is rare and even more significant given that it was realised on industrial textured wafers using a scalable manufacturing method.

“With vapour-deposited perovskites, we are addressing two fundamental challenges at one go: compatibility with real industrial silicon wafers and stable operation under heat,” said Asst Prof Hou. “This is the first evidence of vapour-grown perovskite tandem cells achieving the required durability for commercial deployment, bringing us closer to practical and reliable tandem solar modules.”

The team says it will now work on scaling the vapour-deposition method from small solar cells to large-area modules and integrating the process into pilot manufacturing lines.

“Our next phase is to demonstrate full-size, durable tandem modules under real operating conditions,” said Asst Prof Hou. “This will bring us a step closer to commercial deployment.”