Climate change is one of the biggest challenges facing the world today, and carbon dioxide (CO2) emissions are a major contributor. But what if we could turn emissions of waste carbon into something economically useful?

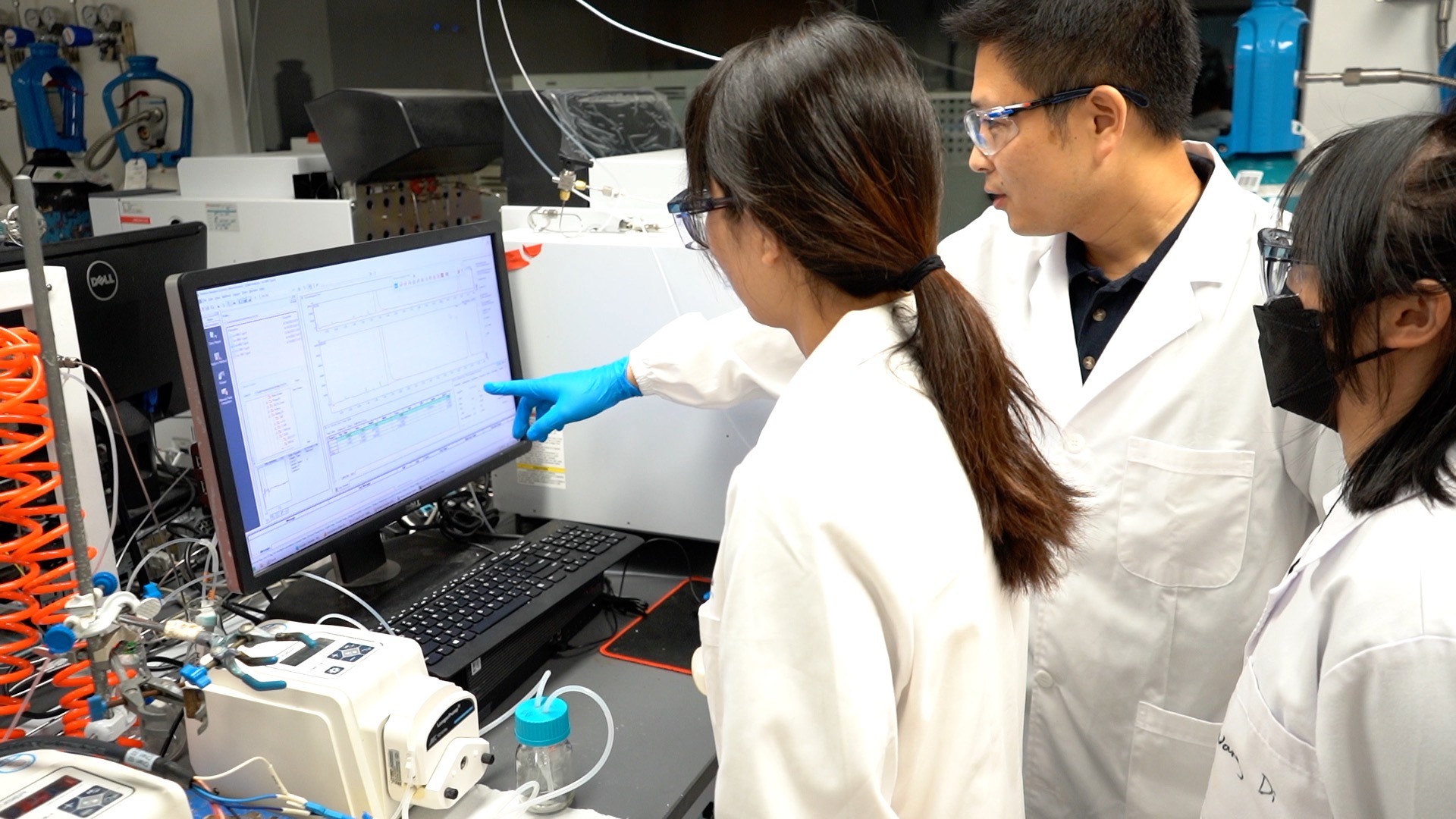

At CDE, Assistant Professor Wang Lei (Chemical and Biomolecular Engineering) has recently published two research papers on breakthroughs in using a process known as electrochemical reduction to simply and efficiently convert CO2 into valuable and widely-used chemicals.

“Finding innovative ways to capture and convert CO2 emissions into economically useful resources could be a major step in combatting carbon emissions and fighting climate change,” said Asst Prof Wang.

“Using electrochemical reduction is not a new process, but until now the challenge has been finding a way to convert CO2 that is energy efficient.”

In one study, published in May in the journal PNAS, Asst Prof Wang and his team developed an innovative palladium catalyst combined with a molecule called polyvinylpyrrolidone (PVP) that efficiently and selectively converts CO2 into formic acid – a chemical widely used in industries including agriculture, pharmaceuticals and textiles as well as a fuel source.

Previous studies using palladium catalysts have shown them to require only low levels of energy input to convert CO2, but they have also proven to degrade quickly in performance making them impractical for use in industrial CO2 conversion.

By adding PVP however, the team found the catalyst could be made more productive, work faster and work for far longer.

“From our experiments so far, we believe our process has high potential for conversion to industrial-scale applications,” said Asst Prof Wang.

CO2 into ethylene glycol

In another study meanwhile, published in the June 2023 edition of the journal Nature Catalysis, Asst Prof Wang and his team report promising results using a similar electrochemical reduction process to convert CO2 into ethylene glycol.

This employs a different catalyst, made of copper, and a two-step “cascade” process – initially converting the CO2 into ethylene and then converting it into ethylene glycol.

An essential chemical compound, ethylene glycol has wide-ranging uses, including as an antifreeze coolant in automotive applications, a solvent in the pharmaceutical industry, and a key raw material in the production of polyester fibers and plastics.

However, current methods of production are extremely energy intensive, requiring very high pressure and high temperatures.

“One of the biggest advantages of our system is that is takes place under ambient conditions,” said Asst Prof Wang. “That means we can use normal temperatures and no high pressure, so it uses much less energy – and the only inputs are CO2, water and electricity.”

Going forward, the team says they will be looking to work with industrial partners to develop the best ways to scale up these processes and develop the most efficient catalysts.

By marrying these processes with renewable and clean forms of energy generation, they say, their research could help to reduce CO2 waste emissions and create a cleaner, greener future for all.