A pioneering design concept for an ammonia-fueled marine engine jointly-developed by researchers at CDE could radically reduce carbon emissions from the world’s shipping industry.

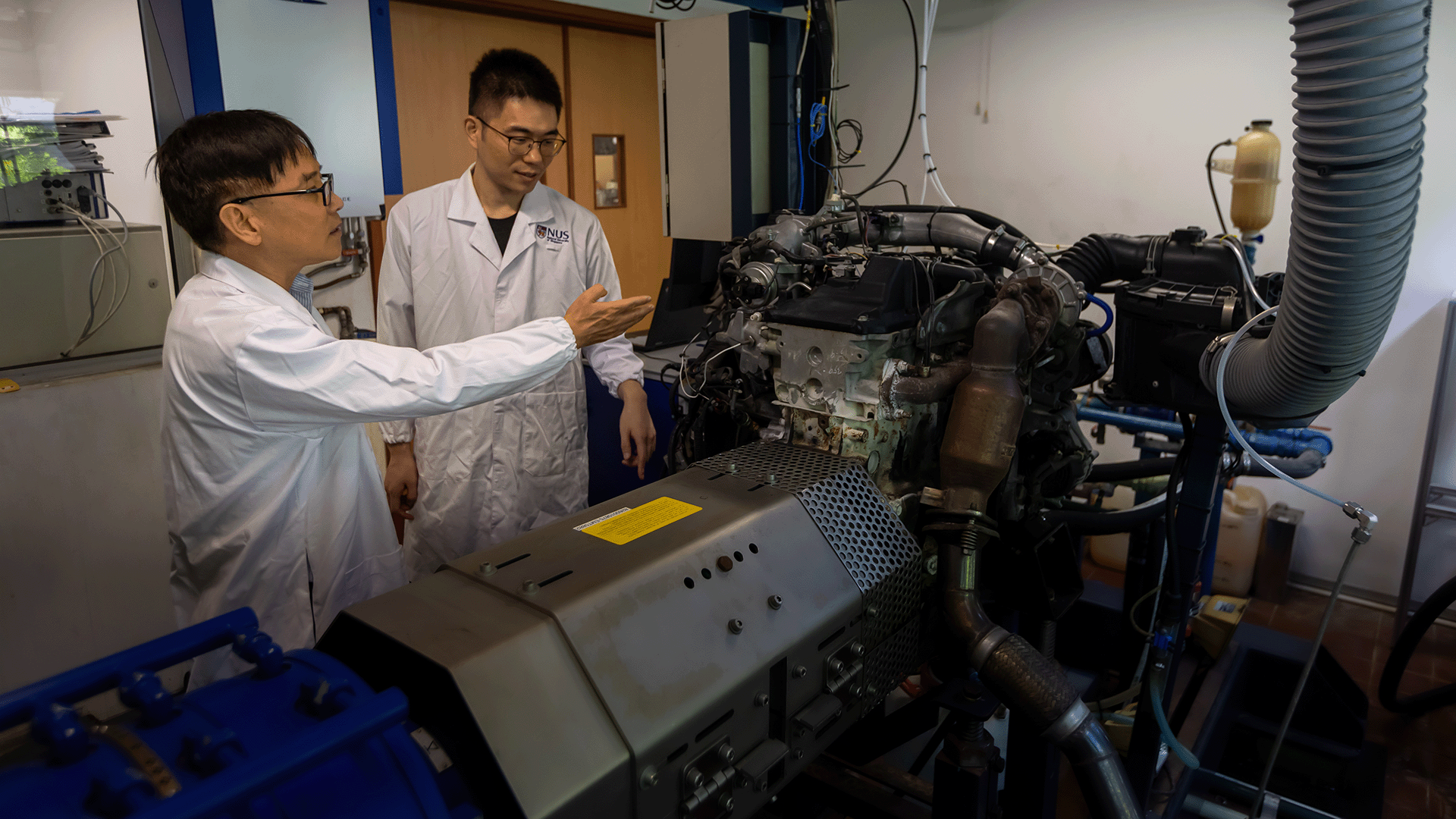

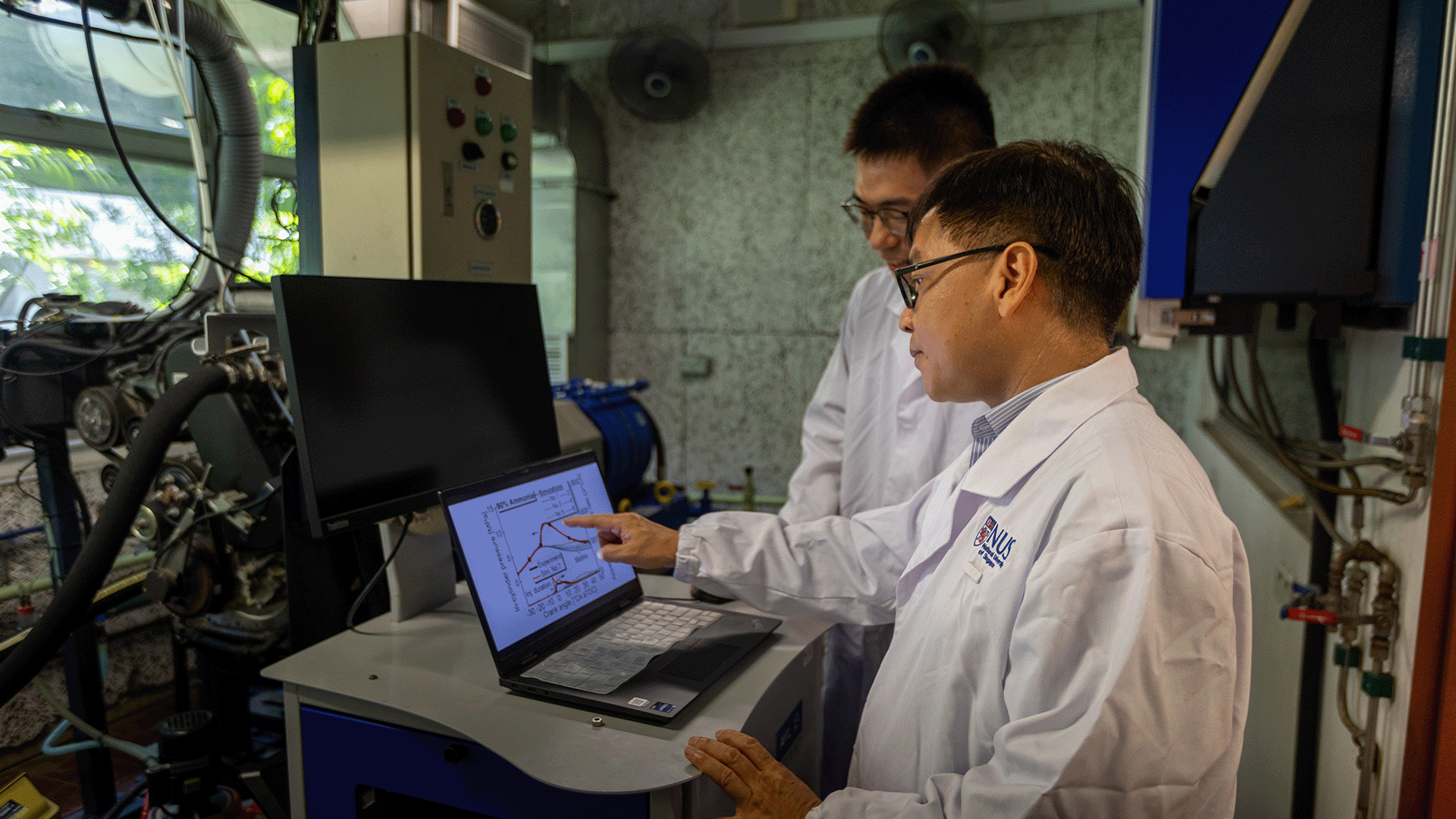

In a joint project led by Associate Professor Yang Wenming (Mechanical Engineering) and Professor Li Tie (Shanghai Jiao Tong University), the research team has devised an innovative design known as In-cylinder Reforming Gas Recirculation (IRGR), which they say could mark a major step towards more sustainable shipping. Their findings were published recently in the journal Nature Communications.

One of the key advantages of the IRGR engine and what sets it apart from traditional engines is its ability to improve combustion performance and efficiency by utilising hydrogen, a highly efficient combustion agent, formed from excess ammonia fuel.

The ammonia molecule is composed of three hydrogen atoms bonded to a single nitrogen atom.

“The IRGR concept operates by using a dedicated cylinder built into the multi-cylinder engine to decompose excess ammonia into hydrogen,” said Assoc Prof Yang. “The exhaust gas with high hydrogen content from this cylinder is then recirculated into other cylinders in the engine to improve the combustion of ammonia, a process that both enhances thermal efficiency but also reduces emissions of ammonia, nitrogen oxides, and other greenhouse gases.”

Thermal efficiency refers to how well an engine converts heat energy into useful work – in other words, how effectively it can turn heat into power or movement.

Net-zero target

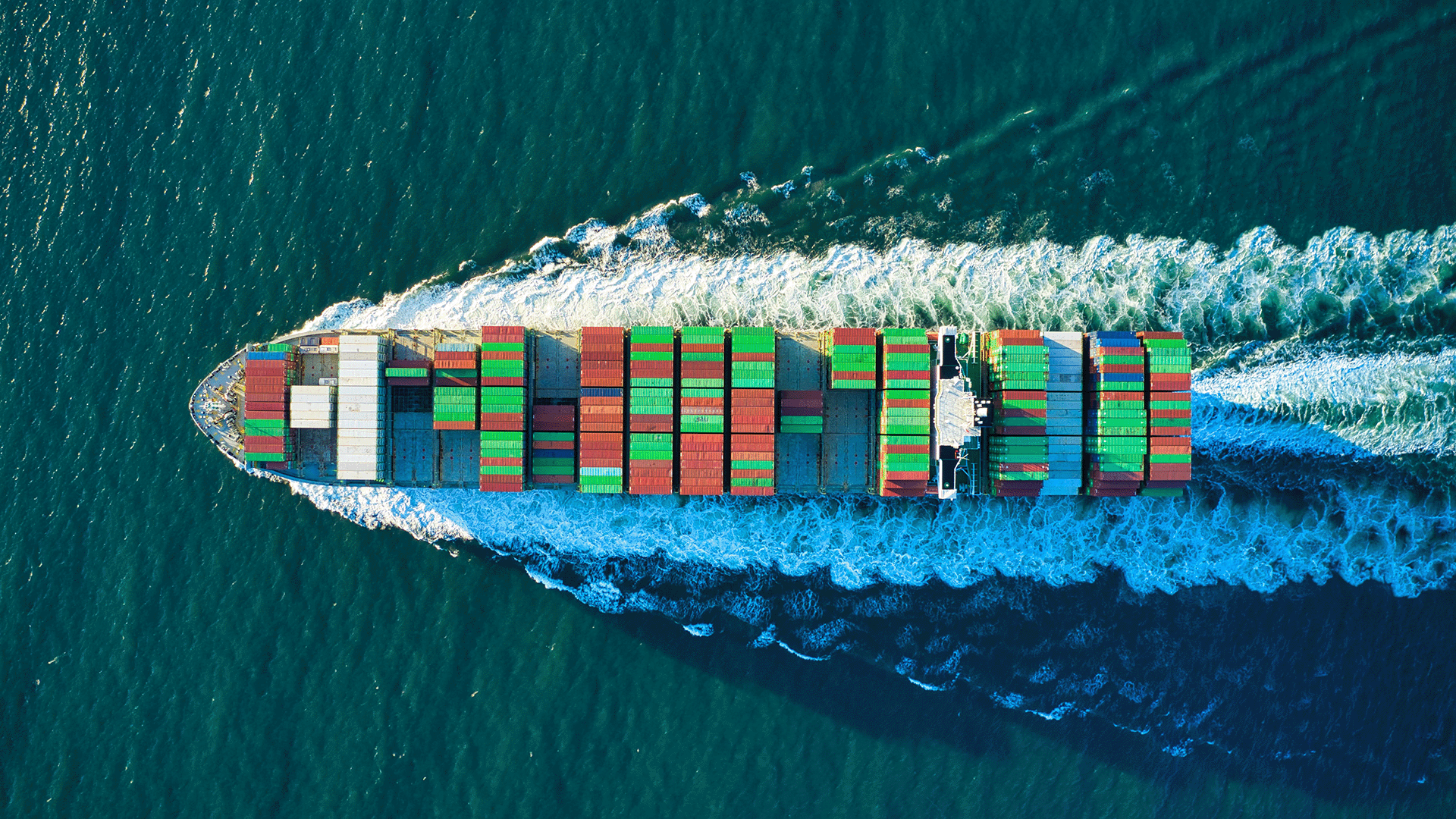

The global shipping industry currently accounts for around 2-3 per cent of global carbon dioxide emissions. With global trade continuing to grow, about 90 per cent of which travels by sea, the International Maritime Organization has set a target of achieving net-zero by 2050, triggering a search for alternative, greener fuels and engines for the world’s shipping fleet.

Compared to hydrogen, another carbon-free fuel, ammonia is considered more suitable for marine use due to its relative ease of storage and transportation, making the costs of liquid ammonia usage much lower than that of hydrogen.

“Prior to our design, a number of bottlenecks had been holding back the application of ammonia in the marine industry,” said Assoc Prof Yang. “For example, ammonia fuel alone has a relatively poor combustion performance, leading to low thermal efficiency and high fuel consumption, as well as emissions of unburned ammonia and nitrogen oxides.”

Using comprehensive 3D modeling, validated by data and numerical resources provided by Prof Li from Shanghai Jiao Tong University, the researchers say they have been able to demonstrate the superior performance of the IRGR engine concept compared to traditional dual-fuel engines.

“Our findings demonstrate remarkable improvements in efficiency and emissions reduction,” said Dr Zhou Xinyi, a post-doctoral research fellow at CDE and first author of the team’s paper. “At three per cent diesel energetic ratio and 1000 rpm, the engine showed a 15.8 per cent increase in indicated thermal efficiency and significant reductions in unburned ammonia and nitrogen oxide emissions.”

The next stage, the researchers say, will be to build an actual working prototype of the engine – a step they say will help position Singapore as a leader in maritime decarbonisation efforts. Furthermore, they say, the technology has the potential to achieve zero carbon footprint if biofuels are utilised, underscoring the versatility and sustainability of the IRGR engine concept.

“We are preparing to apply for relevant patents and exploring collaboration with the Maritime and Port Authority of Singapore as well as leading marine engine manufacturers,” said Assoc Prof Yang.

“Our ammonia marine engine powered by IRGR represents a significant leap forward in sustainable shipping. By leveraging this revolutionary concept, we aim to mitigate environmental impacts while ensuring efficient performance.”

|

Why ammonia?

|

This research work was supported by the funds from National Natural Science Foundation of China and the Dean’s Chair Fund from NUS.