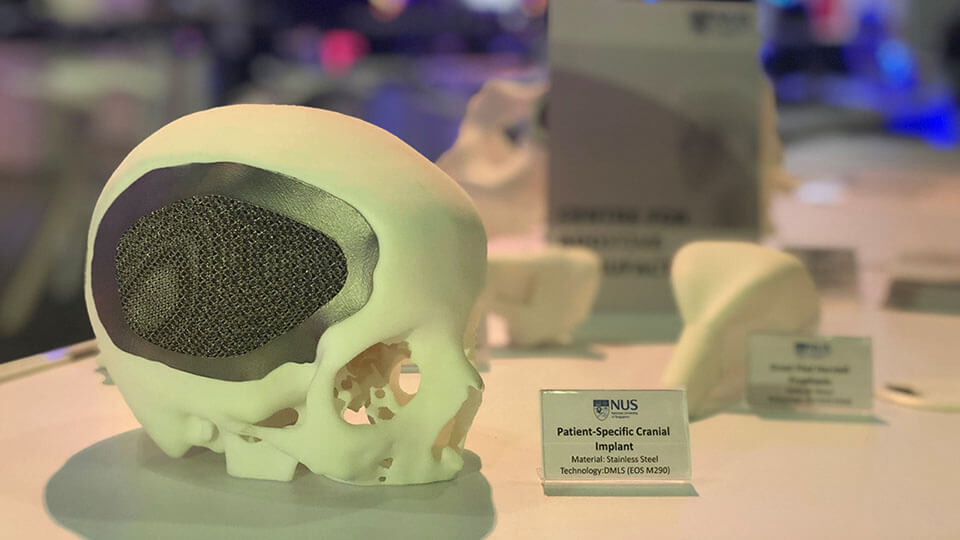

Complicated operations like skull reconstruction and hip replacement could receive a fillip through a new tie-up between NUS Centre for Additive Manufacturing (AM.NUS) and TÜV SÜD to introduce 3D-printed implants in humans.

3D printing - otherwise known as additive manufacturing - has revolutionised manufacturing worldwide with products ranging from jewellery to cars being made using this technique. This involves items being produced from computer designs via material being added layer by layer.

However, the human body has proven to be one of the toughest frontiers for this technology due to health and safety issues. 3D printing centres first need to obtain the ISO 13485 certification, a tough global standard required before they can make implants for humans using additive manufacturing.

AM.NUS wants to obtain this certification so its 3D-printed metal implants can be used in clinical trials and eventually in hospitals. In achieving this aim, it has got the aid of TÜV SÜD, a German safety and quality multinational.

Both parties signed a Memorandum of Understanding on 23 October to cooperate in the areas of research and development, as well as in the certification, inspection and auditing process needed to obtain the ISO certification for AM.NUS' facility located at NUS Engineering.

AM.NUS hopes to obtain the certification by the end of 2020. Once this happens, its 3D-printed personalised implants can be used in patients to improve healing potential and the speed of healing, leading to better patient outcomes.

"Additive manufacturing technology can be considered as a great opportunity to provide easy access to healthcare in developing countries. It is a crucial step towards engineering patient-specific medical products," said Professor Jerry Fuh Ying-Hsi, Director of AM.NUS, at the MOU signing ceremony held at the National Additive Manufacturing Innovation Cluster (NAMIC) summit.

Prof Fuh, also from the Department of Mechanical Engineering at NUS Engineering, added that it is imperative to meet global standards while developing these medical products.

"Partnership with TÜV SÜD is of strategic importance since it will help us achieve global standards while we build and strengthen our base in the region," he said.

Mr Richard Hong, CEO of TÜV SÜD ASEAN, added that additive manufacturing is ushering in a transformation in the production of medical devices as the technology is enabling businesses to push boundaries.

Speaking at the NAMIC summit, Senior Minister of State for Trade and Industry Chee Hong Tat said that additive manufacturing is transforming and disrupting simple manufacturing, lowering the cost and time for rapid prototyping. With this technology, manufacturers can now easily customise the production process, potentially reducing overall time-to-market, he added.

He cited as an example Singapore start-ups Structo and Zenyum, which have a partnership to 3D-print clear aligners for dental use at an affordable pricing. The clear aligners are priced at $2,200, as compared with the current market price of $6,000 to $10,000.

AM.NUS is confident that its 3D-printed implants will revolutionise healthcare in the same way.

This article was first published on 6 November 2019 in NUS News at https://news.nus.edu.sg/research/nus-centre-pushes-3d-printed-implants-humans.