At its heart, engineering is about applying scientific expertise, the latest technologies and human-centred design to improve lives and provide solutions to real-world problems.

The COVID-19 pandemic is a real-world problem writ large: a once-in-a-century global challenge, the scale and speed of which demands urgent action from all of us. Among the scientific community, this urgency has catalyzed a research revolution with interdisciplinary teams of engineers, scientists and health workers coming together to design and develop innovative solutions at an unprecedented pace.

As the virus dictates a new normal in our daily lives, the application of technology will play a central role in shaping the post-COVID-19 future, helping to detect, manage, treat and contain the direction of the pandemic. With luck and the right lessons learned, it could also help us prevent future pandemics.

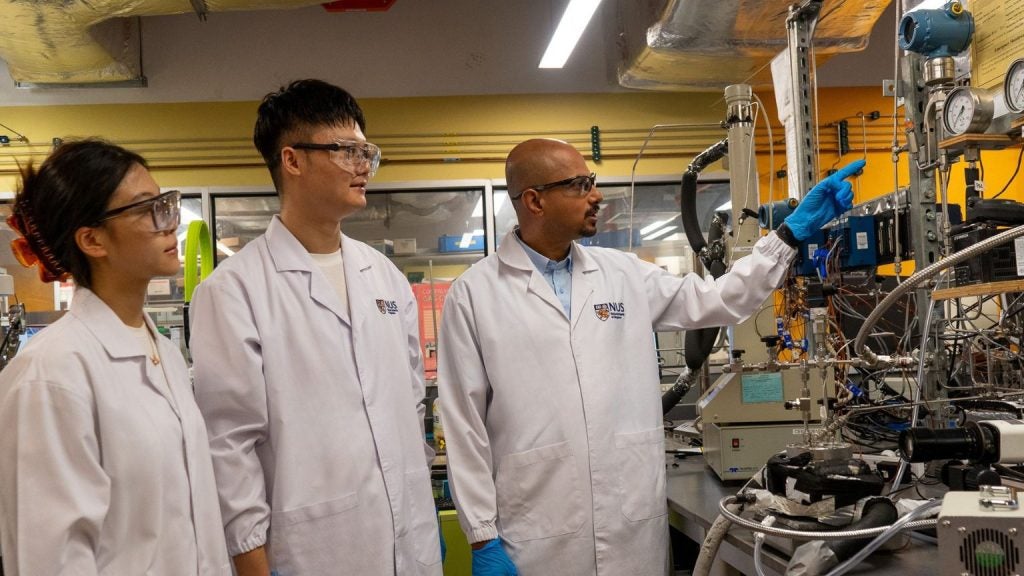

At NUS Engineering, our faculty, researchers and students have been active in driving forward innovations to meet the challenges posed by COVID-19 on a broad range of fronts covering treatment, testing and infection prevention.

Advancing treatment using AI

In responding to a virus that was completely unknown to science just a few months ago, the best immediate hope for treatment lies in repurposing drugs developed for other diseases. But identifying the optimum combination and dosage of drugs can be time consuming and laborious - a process of trial and error that often leads to suboptimal outcomes.

Investigators from NUS Biomedical Engineering at the NUS N.1 Institute for Health have been using Artificial Intelligence (AI) to rapidly process the various possible combinations and identify the best results.

Using a platform called IDentif.AI (pronounced "identify"), initially developed to find better treatments for cancer, the multidisciplinary team has been able to take a shortlist of 12 promising drugs and process billions of possible combinations and dosages at a speed that would be impossible using traditional medical trials.

"The strength of IDentif.AI is that we can perform one experiment and come out with a list of drug combinations for treatment within days. And if patients do not respond well to the first combinations of drugs, we can derive new combinations within days to re-optimise their care." - Professor Dean Ho, Head of NUS Biomedical Engineering, and Director of NUS N.1 Institute for Health

Read more about IDentif.AI and the development of COVID-19 treatment here

Quick, simple and portable testing

Effective testing is a key part of curbing and containing the spread of the pandemic.

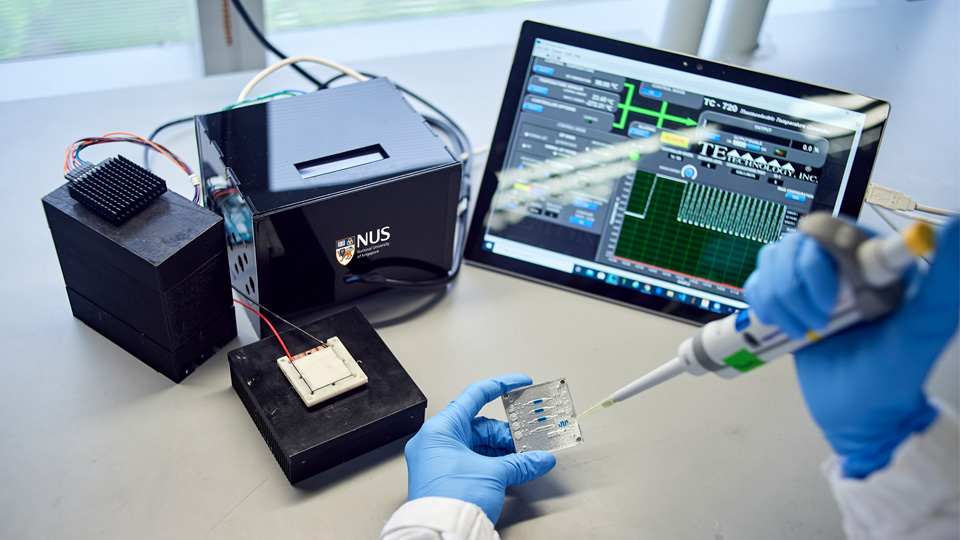

Using a machine about the size of a household toaster, a team at NUS Institute for Health Innovation & Technology (iHealthtech) led by Professor Lim Chwee Teck of NUS Biomedical Engineering has developed a system for testing patients quickly, easily and on location. This avoids the need for samples to be sent to specialised lab testing facilities saving time, effort and cost.

The Epidax system is built around a specially designed chip and microfluidic technology that uses a smaller sample than standard diagnostic tests and returns results in around an hour. It was developed and tested from scratch in less than two months, despite the challenges researchers faced working under the restrictions imposed by Singapore's Circuit Breaker.

"By enabling rapid, simplified yet highly accurate testing on site - such as at local clinics, care homes or airports - the Epidax system will enable us to identify infections and speed up action to prevent transmission," - Professor Lim Chwee Teck, NUS Biomedical Engineering and Director, NUS Institute for Health Innovation & Technology

Read more about the development of Epidax here

3D printed testing swabs

Another challenge hampering efforts to expand mass testing has been a global shortage of nasal swabs. To address this, NUS Engineers joined forces with medics and industrial designers to rapidly develop new processes to mass produce swabs cheaply and accurately.

One kind of swab, named Python, is produced using 3D printing techniques developed by the NUS Centre for Additive Manufacturing (AM.NUS). 3D printing the swabs allows far faster production at scale than would be possible under traditional manufacturing techniques.

The team developed a special double helix design for the swab tip that has excellent fluid absorption properties and causes minimal pain for the patient when a sample is extracted from the back of the nasal cavity.

The Python swab was designed, developed and had a patent filed in less than two months, with two local Singapore companies now mass producing the swabs. As part of NUS's contribution to the fight against COVID-19, it has also been made free for use in Singapore.

Read more about the Python nasal swab here

Facial protection for the frontline

Facial masks have become a vital tool in preventing transmission of COVID-19. But for frontline medical and care workers most commonly available masks are uncomfortable to wear for extended periods or do not provide maximum protection.

Using the latest 3D printing techniques and advanced materials, a team from NUS Mechanical Engineering attached to the NUS Centre for Additive Manufacturing (AM.NUS) is working with healthcare workers to rapidly prototype a comfortable, ultra secure, reusable mask.

3D printing enables the team to rapidly produce and test design variations, whilst the advanced printing machines available at NUS allow the developers to test multi-material combinations that deliver the optimum combination of comfort and effectiveness.

"As well as designing masks that are comfortable to wear, safe and recyclable, another factor in making masks usable is for them to be as unobtrusive and patient-friendly as possible." - Professor Jerry Fuh, NUS Mechanical Engineering, and Director, NUS Centre for Additive Manufacturing

Read more about the team developing the 3D printed masks here

Shielding healthcare workers

Without effective barrier protection, treating patients infected with highly contagious pathogens like COVID-19 exposes healthcare workers to considerable risk. Procedures such as installing and removing tubes for assisted breathing - something often required by seriously ill patients - can be especially risky.

To reduce the chances of infection spreading, NUS Engineering researchers have been a key part of a collaborative effort with doctors and frontline caregivers to develop a portable and easy to clean shield.

Transparent, foldable and similar in appearance to a laboratory glove box, the DART, short for Droplet and Aerosol Reducing Tent, is placed around the patient's head and is equipped with an air extractor and filter at the top to further reduce the chances of infected droplets leaking out.

Working in close collaboration, the DART team developed the shield in less than two months, with prototypes being tested in hospitals across Singapore. Once finalized it hopes to offer the shield as a form of medical aid to Singapore hospitals and to medics across Asia.

Read more about the DART shield here

More stories on NUS Engineers in the fight against COVID-19 may be found in Issue 122 (Jul-Sep 2020) of the AlumNUS, the magazine for NUS Alumni.