A common waste product left over from kombucha brewing could soon play a role in sustainable electronics. Researchers from the College of Design and Engineering (CDE) at the National University of Singapore have found that the thick cellulose film left after fermentation can be processed into smooth, flexible, and conductive materials suitable for eco-friendly electronic applications.

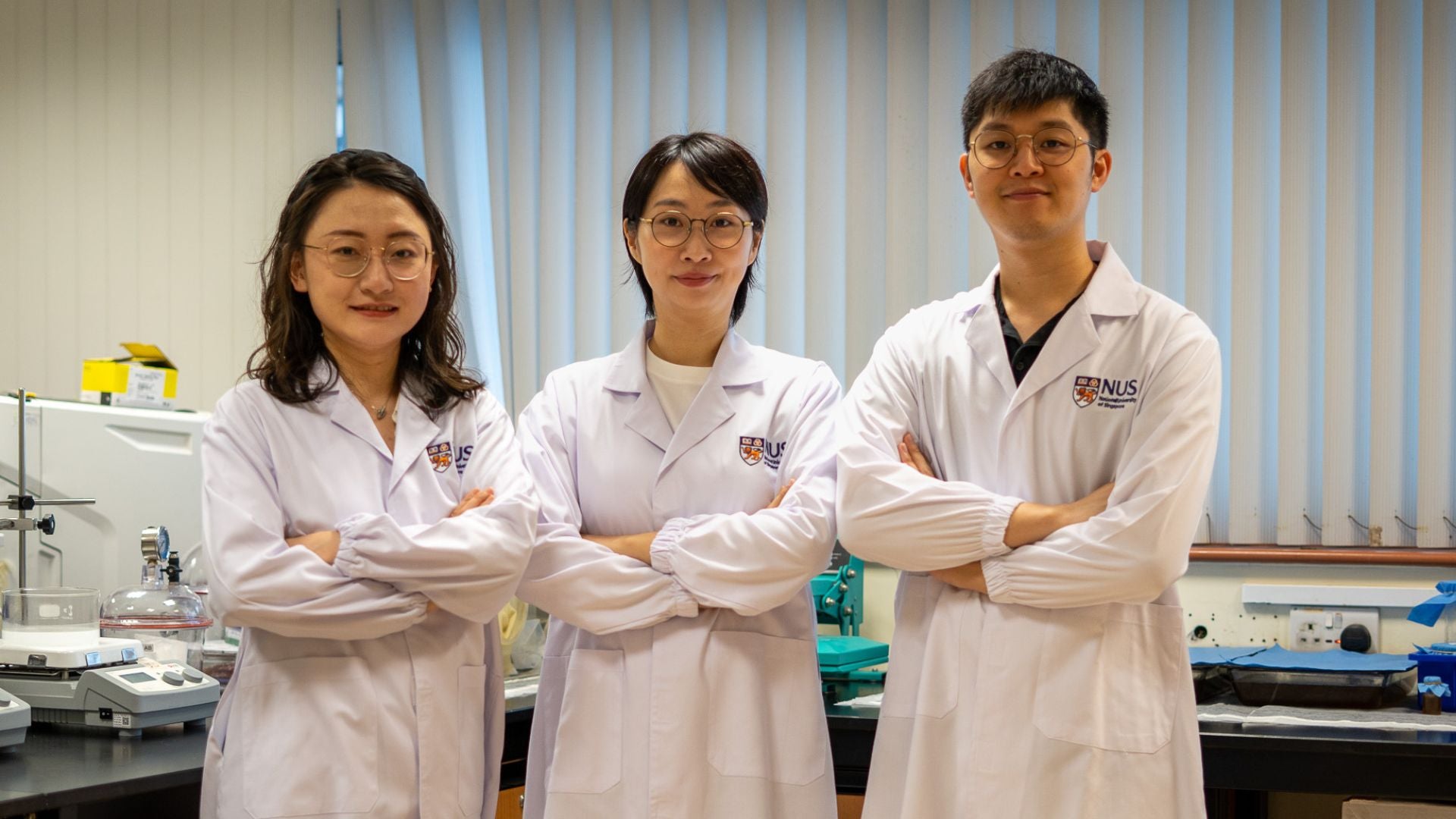

The study was led by Assistant Professor Tan Yu Jun from the Department of Mechanical Engineering at CDE and published on 17 October 2025 in Advanced Science. The research demonstrates how bacterial cellulose from kombucha waste can be upcycled into biodegradable substrates suitable for sensors, wearables, and short-lifetime or “transient” electronics.

Transforming fermentation waste into high-performance material

The idea stemmed from Asst Prof Tan’s personal interest in kombucha brewing.

“After fermentation, a thick cellulose layer forms on the kombucha surface. Most people discard it, but as a materials scientist I was struck by how strong, smooth, and flexible it was,” she said. “I realised it’s actually pure bacterial cellulose, a biopolymer known for its exceptional mechanical strength and purity. That’s when the idea clicked: this ‘waste’ could be a renewable, high-performance material for electronics.”

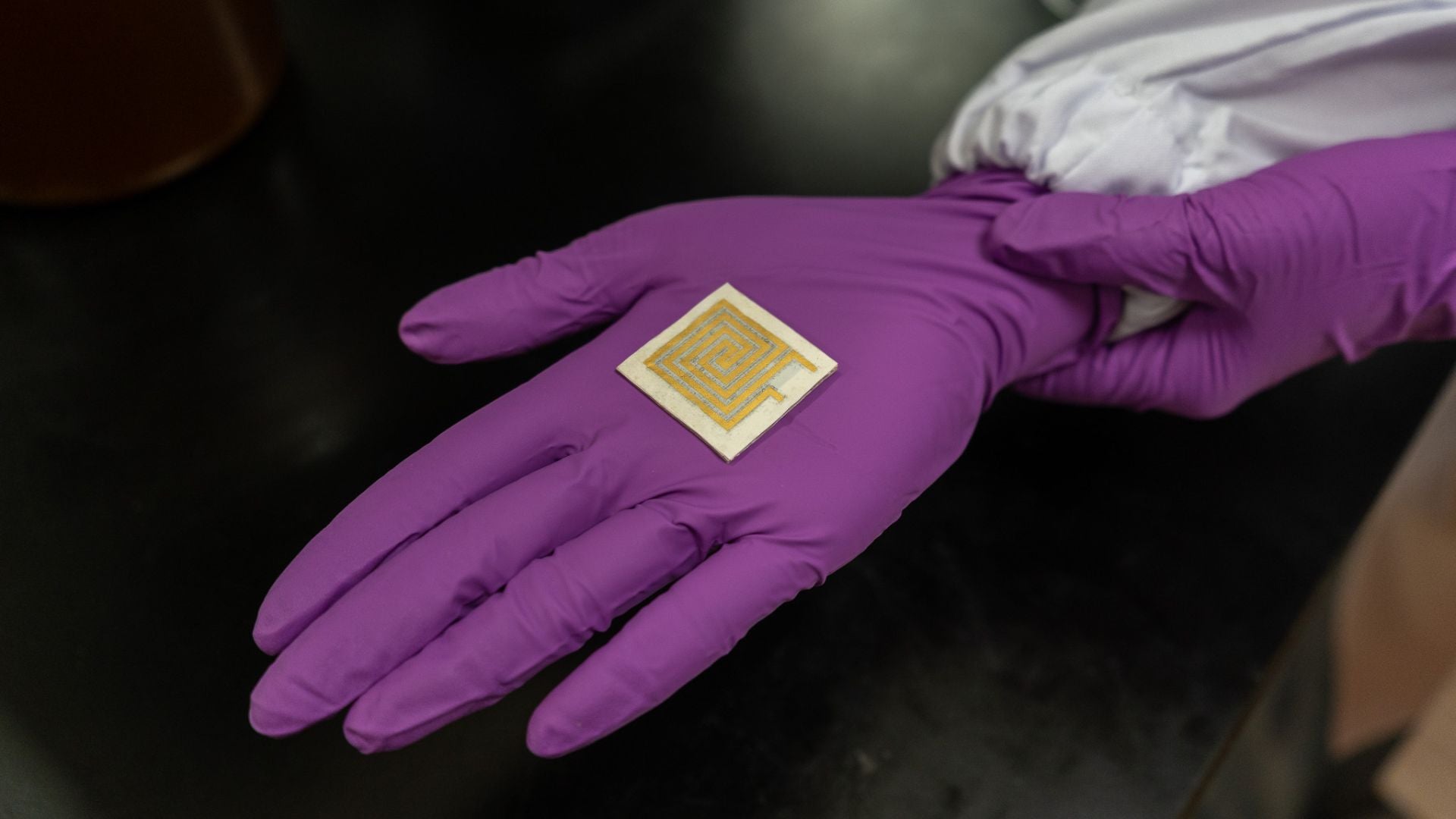

Bacterial cellulose produced during kombucha fermentation is naturally pure and made up of a fine network of nanoscale fibres, a thousand times thinner than a strand of human hair. This tightly interwoven structure gives the material its exceptional strength, smoothness, and flexibility without the need for synthetic additives. To purify the waste cellulose, the researchers developed a simple, non-toxic process using only baking soda and hydrogen peroxide to remove fermentation residues such as yeast and sugars. The resulting film is smooth, white, and flexible, forming a biodegradable base for printed electronic circuits.

Flexible, durable and biodegradable

When printed with gold circuits and subjected to repeated bending and folding, the conductive tracks remained intact, demonstrating mechanical stability suitable for flexible devices.

Compared with cellulose papers made from wood pulp, the bacterial cellulose films have a finer and more uniform nanofibre network. This produces smoother surfaces and higher tensile strength, enhancing compatibility with electronic inks and coatings. The material also biodegrades within days in soil, helping close the loop between use and disposal.

Toward circular and sustainable electronics

The researchers see a range of potential uses for the kombucha-based films including biodegradable health patches for physiological monitoring, temporary medical implants that dissolve after healing, environmental sensors for soil and water quality, and smart packaging that monitors freshness or temperature.

“Our kombucha-derived films can be used in any application that requires flexible, lightweight, and environmentally friendly substrates,” said Asst Prof Tan. “Right now, we’re focusing on transient electronics, which are devices that are designed to function for a specific time and then safely degrade.”

Because kombucha waste is abundant and the purification method relies on inexpensive, non-toxic ingredients, the production cost is expected to be significantly lower than that of conventional polymer substrates. The same mild cleaning process could also be adapted to other cellulose-rich food-industry residues, such as those from vinegar or fruit processing, broadening its potential industrial relevance.

Next steps

The team is now collaborating with partners to integrate the material into more complex device architectures and to explore 3D printing of conductive traces directly onto the films.

Prototype-level demonstrations are expected within the next two to three years, particularly for short-lifetime devices such as disposable sensors.

“In nature, nothing is wasted. Everything becomes part of a new cycle,” said Asst Prof Tan. “Turning something that usually ends up in the bin into a functional electronic material felt like a perfect example of circular design.”