As cities grow denser and construction labour becomes harder to secure, the sector is under pressure to deliver projects faster, more efficiently and with fewer workers on site. In the past decade, 3D concrete printing (3DCP) has emerged as a promising solution to these challenges thanks to its high degree of automation and its formwork-free feature. However, 3DCP is still limited to non-structural applications for the built environment in Singapore.

Led by Senior Lecturer Dr Du Hongjian and Associate Professor Pang Sze Dai from the Department of Civil and Environmental Engineering, the team has successfully shown that 3DCP can be used to fabricate structural building components that are greener, use less material and require fewer workers, while still meeting structural performance requirements. For the construction sector, this means faster project delivery, lower labour dependence and greater flexibility in how modular buildings are designed and built.

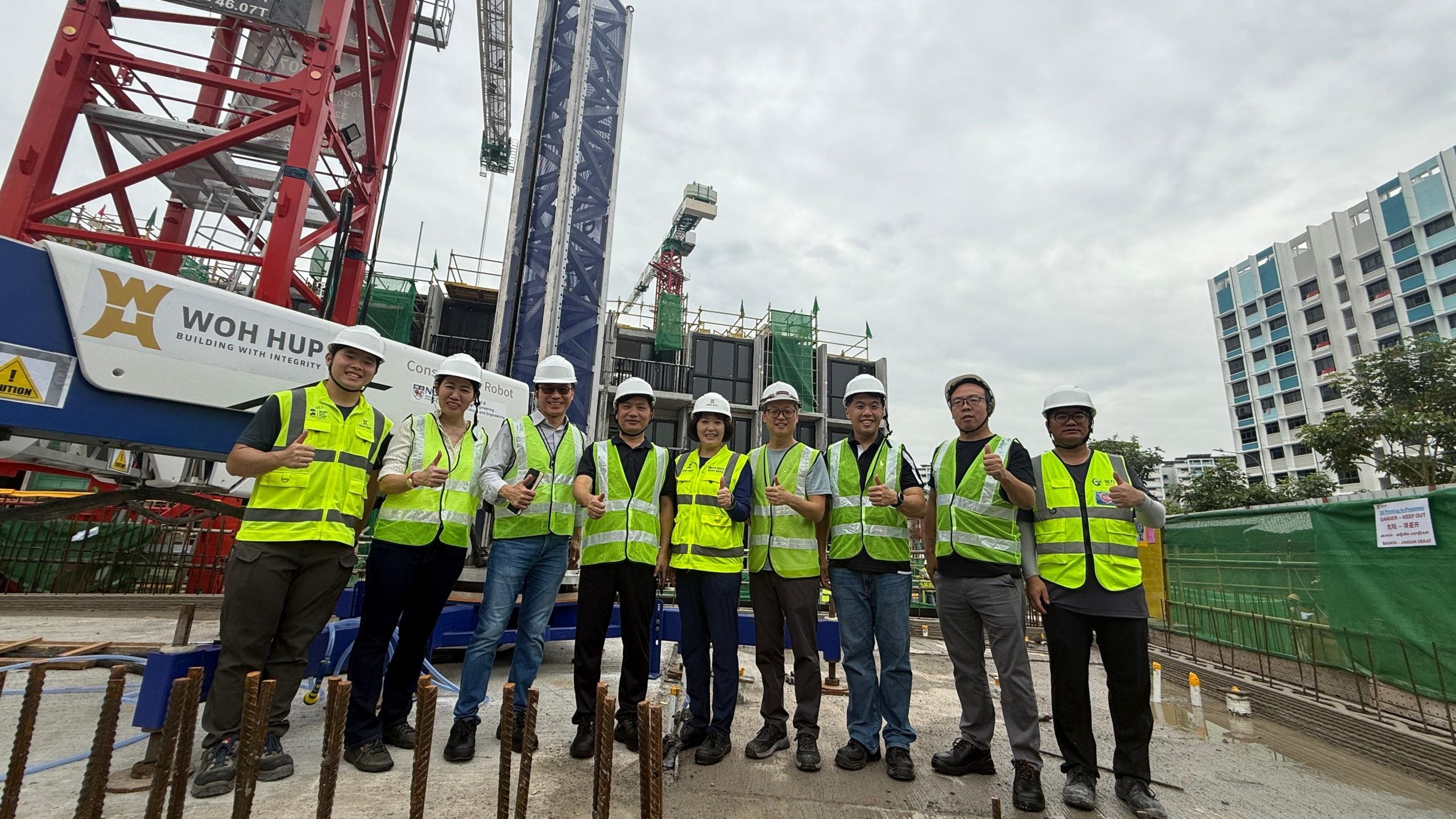

With a focus on making 3DCP viable for real-world construction environments, the work was carried out in collaboration with construction firm Woh Hup and supported by the Building and Construction Authority (BCA), and the National Additive Manufacturing Innovation Cluster (NAMIC), a national platform hosted by the Agency for Science, Technology and Research (A*STAR).

Enabling 3D concrete printing for structural components

3DCP enables the fabrication of complex shapes without formwork and with minimal manual labour. However, due to its limitations, currently most real-world applications remain confined to non-structural elements or low-rise buildings — formats that are not well suited to land-scarce, high-density cities like Singapore.

The team focused on a more practical challenge: how to harness 3DCP for structural components. Its approach integrates formwork-free 3D printing with conventional construction, allowing structural elements to be fabricated with greater design freedom and material efficiency.

The team addressed two foundational facets of deployment: material formulation and construction workflow. They developed printable concrete mixes optimised for extrusion and buildability, structural reinforcement and compatibility with current structural components production. In parallel, the researchers defined a fabrication workflow aligned with existing prefabrication and on-site construction processes, ensuring that the printed components were not just structurally viable but also practical to produce and deploy at scale.

Through a series of laboratory and large-scale tests, the researchers assessed the structural behaviour of reinforced 3DCP elements designed for structural components. The results showed that these elements could achieve the required load-bearing performance while using significantly less material compared with conventional designs. Importantly, automation reduced reliance on manual labour, delivering more than 40 per cent manpower savings and efficiency gains of over 60 per cent for complex components, based on industry evaluations. This translates into faster construction, lower labour demand and more predictable project delivery.

By removing the need for traditional moulds, the approach also tackles one of concrete structure’s major cost drivers. Each conventional concrete structural component typically requires its own mould, which is expensive to fabricate and can only be used for a limited number of times. Formwork-free printing sidesteps this issue entirely, opening the door to more flexible designs and faster production cycles. It is also estimated that 3D concrete printing uses 30 per cent less material compared to conventional construction technologies.

From research to construction sites

Woh Hup worked closely with the CDE researchers to assess how 3D-printed structural components could be fabricated and deployed under real construction conditions. This included evaluating buildability and on-site implementation, as well as how 3DCP could be integrated into existing prefabrication and site workflows. “Testing the novel technology beyond the lab enables all parties to pinpoint practical constraints and opportunities for improving productivity and reducing manual labour in construction”, added Mr Yong Derong, Executive Director, Woh Hup.

In August 2025, the collaboration led to Singapore’s first on-site 3DCP of structural elements, which was verified by BCA. The project achieved a 50 per cent reduction in manhours, providing a real-world testbed for the technology. A second on-site printing exercise started on 29 January 2026, further validating the approach under operational conditions.

“Construction innovation only matters if it can be applied on site,” said Assoc Prof Pang. “Working directly with industry partners enables us to test these technologies against real constraints and build confidence for wider adoption. We hope to continue in this partnership with BCA and the Built Environment (BE) industry to further improve these technologies, to bring about even greater gains in productivity.”

“This project was ground-breaking as it was the first in Singapore to be carried out on site for structural elements. As the BE sector’s champion for innovation and collaboration, BCA supported the project team and facilitated the implementation of the technology. The experience demonstrates how strategic collaboration allows academia, firms, and government agencies to complement one another, uplift our capabilities, and bring about tangible productivity improvement. The success of this project also positions Singapore as a regional leader in construction innovation and opens numerous possibilities for future development.” said Er Lim Kheng Guan, Deputy Director from BCA’s Building Engineering Group.

In addition, support from NAMIC has helped bridge the gap between research and application, enabling large-scale testing, performance evaluation and engagement with industry and regulatory stakeholders. “Together, these efforts position 3DCP as a practical tool for improving productivity, reducing manpower requirements and supporting safer construction practices in Singapore,” added Dr Du.

“We are working with the NUS team to identify and develop further applications of 3DCP for other projects and potential use cases. By testing the technology in real project settings, we can better understand its practical requirements, cost implications and scalability, which are critical for responsible adoption in the industry,” said Er Cong Zhengxia, Senior Technical Director, Woh Hup.

The BCA has offered early and outcome-based regulatory support, giving industry stakeholders the confidence to trial this novel construction technology within a compliant and safe framework. Their strong endorsement and facilitation increased the confidence of key stakeholders, including the Qualified Person, to proceed with structural 3DCP.

The team’s work aligns closely with Singapore’s national push to transform the built environment sector through advanced construction technologies. By reducing manpower needs, improving productivity and enabling more efficient use of materials, 3DCP supports the RIE2025 Urban Solutions and Sustainability domain and the Resilient Future pillar of the Singapore Green Plan 2030, particularly in construction automation and resource efficiency.

In parallel, the team is also developing lower-carbon 3D printing materials using locally available waste resources, further strengthening the sustainability case for scaling up 3DCP in Singapore’s construction industry.

Reducing the carbon footprint of 3D concrete printing

Alongside advances in 3DCP for prefabricated construction, the NUS team is also addressing one of the technology’s key environmental challenges: the high cement content typically required in printable concrete.

In a study published in the scientific journal Construction and Building Materials on 30 January 2026, the researchers developed a 3D-printable concrete mix that replaces 60 per cent of ordinary Portland cement with recycled waste glass powder, while retaining the printability and structural performance needed for construction applications. Laboratory tests showed that the material could be successfully 3D-printed into full-scale elements without collapse or deformation, and still achieved compressive strengths exceeding 50 megapascals, suitable for structural components.

Compared with conventional printable concrete, the high-volume glass powder mix reduced embodied energy by 44 per cent and carbon dioxide emissions by 52 per cent. It also demonstrated significantly improved resistance to chloride penetration, indicating a longer service life and lower maintenance demands over time. The team’s study demonstrates how 3D concrete printing can be paired with low-carbon material design, supporting Singapore’s broader sustainability goals while making digital construction more viable for real-world deployment.

For more on related research, check out the Centre of Construction 3D Printing Research.