How many ways can you use a pineapple? Perhaps in a piña colada? An upside down cake? Or perhaps even let it squat contentiously on a pizza? (The horror!)

Now, in a fresh use for the spikey fruit, NUS Engineers have cooked up a recipe to turn pineapples into biodegradable aerogels - versatile and ultra-lightweight materials used in a range of applications from heat and sound insulation to filtering out pollutants.

Originally from South America, Pineapples are one of the most widely-produced tropical fruits. In the right climate, they grow easily and are so prolific that for each kilo of fruit produced, almost three times as much pineapple leaf waste is generated. Farmers saddled with this bulky and fibrous by-product usually burn, compost, or repurpose it as animal feed.

But whilst others saw just low value plant waste, NUS Associate Professor Duong Hai Minh saw the raw ingredient for a versatile environmentally-friendly material and a new source of revenue for pineapple farmers.

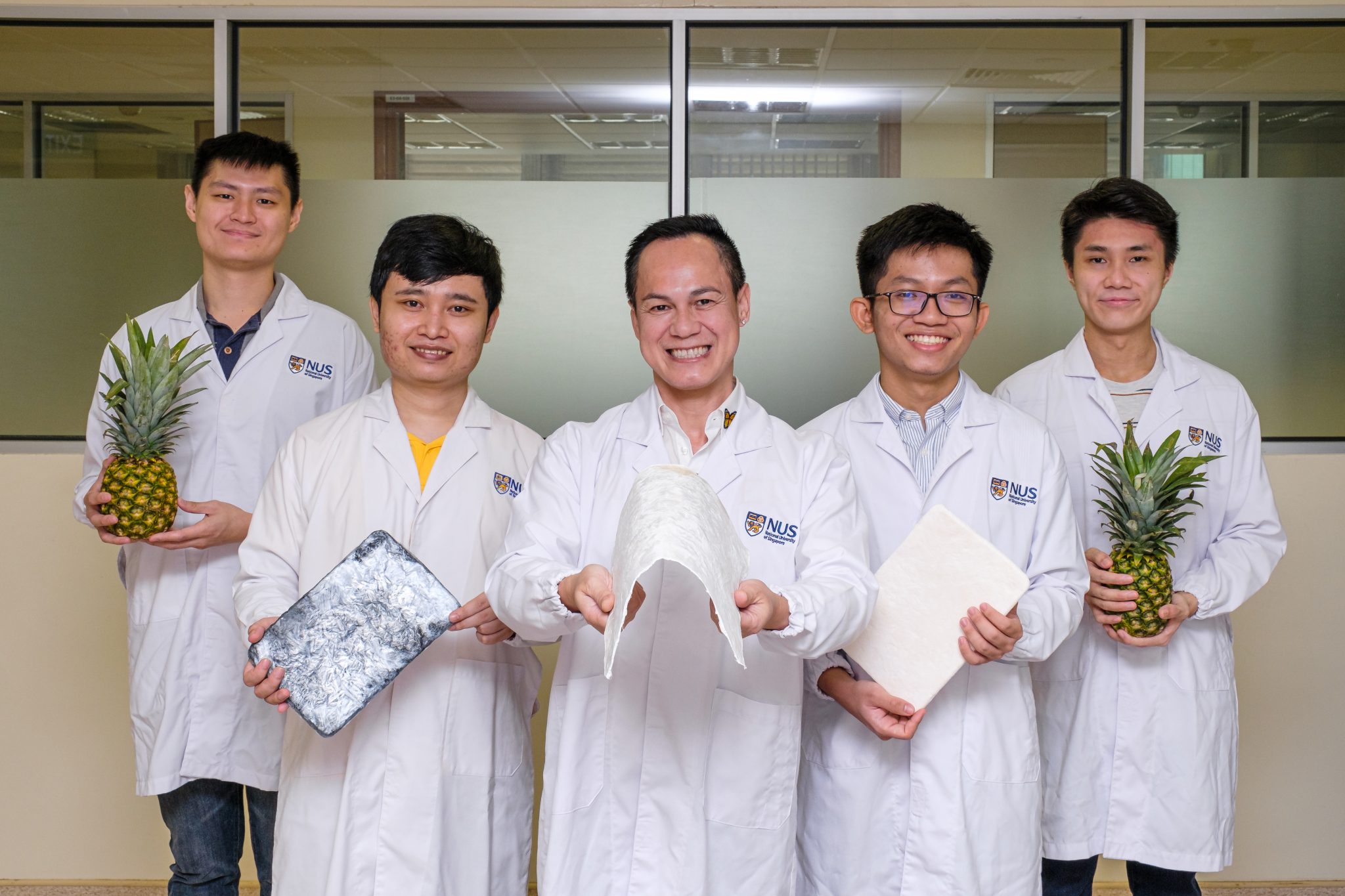

Together with researchers from the Department of Mechanical Engineering, Prof Duong has developed a simple, low cost and sustainable process for transforming waste pineapple leaves into high value aerogel.

New aerogel, new applications

This is not Prof Duong's first foray into recycling materials into aerogels; he holds patents for aerogels made from old tyres, coffee grounds, and plastic bottles. By recycling waste as raw materials and improving the manufacturing process, he hopes to make aerogels more marketable. "Aerogels are one of the most promising materials of the next century. But when I saw the price of aerogels, it was very high," Prof Duong says. "There were a lot of technical problems with commercialisation, and I felt there was room for me to improve on those."

The new pineapple aerogels are the latest in their series of eco-aerogels. Compared to the more common aerogels made from silica, it performs as well or better in applications such as heat and sound insulation. However, by adding thin layers of various chemical coatings to the aerogel, the NUS team found a number of novel uses too.

For example, a small piece of the pineapple aerogel coated with non-toxic activated carbon can help to preserve fruits and vegetables, preventing them from rotting for at least two weeks. This is because the carbon-coated aerogel absorbs the plant-ripening hormone ethylene, extending the lifespan of the produce.

In another application, coating the pineapple aerogel with a chemical called diethylenetriamine (DETA) turns it into an effective remover of toxic heavy metal particles from industrial wastewater. Compared to expensive purification processes, this offers a simple and cheap solution for water treatment and cleaning up pollution.

"The role of the aerogel is to provide a pillar for the chemical additives to cling onto, increasing their surface area," says Lim Zi En, a final-year mechanical engineering undergraduate on the team. "With more surface area, the additives are much more effective."

A green material

Unlike silica-based aerogels, the pineapple aerogel is quick and cheap to produce - the finished product takes just 12 hours to make compared to as long as a week for other aerogels, and it can be produced at a fifth of the wholesale price of commercial aerogels. Even more significantly, it requires no use of toxic solvents in the manufacturing process.

"These eco-aerogels made from pineapple leaf fibres are very versatile," says Prof Duong. "We have demonstrated their potential applications in food preservation and wastewater treatment. This is a big step towards more sustainable agriculture and improved waste management."

From start to end, the new pineapple aerogel promises to be an extremely green material.

With his team's work, what was once seen as low value agricultural waste looks set to find new life as a biodegradable aerogel, helping the environment - and potentially helping pineapple farmers earn added income while dealing with their mountains of leaves.