Follow CDE on Socials

Dr Zhang Sui

Assistant Professor

Department of Chemical and Biomolecular Engineering

Follow CDE on Socials

To advance sustainability efforts, Assistant Professor Zhang Sui is developing highly efficient membrane technologies for a broad range of separation applications across industries.

The stereotypical picture of a scientist is likely one who mixes a concoction of various chemicals to generate a desired product. But just as important are researchers working on the reverse process—separation—to retrieve individual components.

“Separation is an essential process in industry and in life,” shared Assistant Professor Zhang Sui from the Department of Chemical and Biomolecular Engineering at the College of Design and Engineering, NUS (CDE). “In living organisms, for example, the membranes that surround each cell not only demarcate a clear separation from the external environment, but are also selectively permeable to only allow specific compounds to pass.”

Such filtering functions are also the crux of water purification strategies to get rid of salts, microbes and other miniscule contaminants. Membrane technologies currently enable more than half of desalination or salt removal efforts to transform seawater into a usable resource for the world, according to Zhang.

These applications are poised to become even more important in the near future, as Asia and the globe brace for the devastating impacts of water scarcity. Without significant interventions, the demand for clean water is predicted to surpass the available supply by as much as 40 per cent by 2030, aggravating the over two billion people already living in water-stressed communities.

To help address this pressing issue, Zhang returned to her alma mater in 2017 after her postdoctoral training at the Massachusetts Institute of Technology and established the Advanced Membrane Lab at NUS. From the fundamentals of materials science to industry-ready inventions, her research group is zooming deep into the molecular structure of membranes and engineering novel technologies for high efficiency separation applications.

Filtration without fouling

Although membrane-based water purification consumes less energy compared to other techniques, the process still relies on a lot of power. Simply banking on the water to freely flow through the filter leads to a terribly inadequate output of clean water, so water treatment systems must expend significant energy to create pressure gradients that push the water through the membrane.

Aside from minimising energy costs, Zhang and her team must also design membranes that can reject the unwanted chemicals and microbials swimming amidst the water molecules. However, improving the membrane’s salt rejection often means sacrificing the speed and volume of water flow, also called flux.

While blocking these compounds, the membrane itself can become contaminated as the pollutants latch onto its surface. Just like a drainage clogged with muck, the accumulation of these foulants can block the pores or holes of the membrane, drastically diminishing the water flux rate.

“Fouling has been a long-lasting challenge in membrane processes, as it leads to high energy consumption. Cleaning the membrane also requires the extensive use of chemicals that are harmful to the environment,” Zhang explained. “Moreover, existing methods to improve the anti-fouling properties involve complex synthetic procedures that prove difficult to scale up for industry-level production.”

But Zhang is on a mission to overcome these trade-offs. By understanding how different physical and chemical modifications affect surface chemistry, she and her collaborators can manipulate membranes on the structural level and tune them for enhanced fouling resistance while maintaining high water flux.

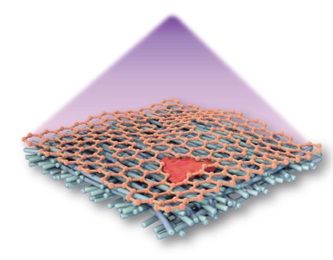

In 2020, Zhang’s team invented a patented membrane technology that achieved these two elusive properties in tandem. The membrane was attached with a copolymer made of zwitterions—molecules that contain equal numbers of positively and negatively charged functional groups.

Zhang highlighted that these zwitterions repel a wide variety of foulants, from organic and inorganic compounds to biological species, that are commonly found in municipal wastewater. Strikingly, the copolymers also bind to the loose chains present on the membrane, dragging them away from the surface. Thanks to the removal of these loose chains, membrane thickness declines and more pores can form, boosting the water permeability.

“By employing a green synthesis protocol, we designed the membranes to be more resistant to contamination by pollutants, which significantly reduces the use of chemicals,” Zhang said. “Also, with higher flux rates, lower pressure is required to produce the same amount of water—saving up to 40 percent of energy.”

The team’s anti-fouling membrane technology boasts a pure water permeability of up to 10 LMH bar-1 and a salt rejection capacity of 98 per cent.

Extracting the essentials

Beyond purifying water, membrane separation techniques are vital for sustainability as they provide a means to extract useful elements that could be reused in other processes. Organic solvents, for instance, are particularly relevant for various manufacturing and chemical industries. To recover the costly material which would otherwise cause serious environmental concerns if disposed of, Zhang turned to monolayer graphene, which opens the possibility for creating the thinnest membrane in the world—save for its instability and susceptibility to defects.

By joining forces with computational simulation experts, Zhang and colleagues harnessed the power of computing to simulate the molecular dynamics of how different solvents and support structures interact with monolayer graphene. Equipped with a deeper understanding of these interlayer interactions, the researchers developed a universal platform that exploited such binding chemistry, facilitating the transfer of graphene onto appropriately porous supports to enhance its stability.

Their approach led to developing a graphene-based membrane as a nanofilter for organic solvents. “Our membranes showed exceptional flux in the recovery of organic solvents. This technology could potentially reduce the energy costs and environmental impacts of handling such solvents in the fine chemical and pharmaceutical industries,” said Zhang.

With an eye for industrial impact, Zhang relentlessly explores new horizons in membrane development, banking on fruitful collaborations to translate fundamental science into a kaleidoscope of applications. Her team is now making strides in creating hollow fibre membranes that can capture carbon dioxide from power plant emissions—yet another critical facet in the movement towards sustainability.

“We continue to work closely with the industry to evaluate our membranes in various realistic contexts to fully explore the potential for practical applications,” Zhang said. “Research gives us the opportunity to continuously refresh our minds. Even in the face of challenges and frustrations, I believe everything will eventually work out with stepwise efforts.”

People

Zhang Sui ▏ Assistant Professor, Department of Chemical and Biomolecular Engineering ▏ LinkedIn Profile

Related Departments/ Centres

If you are interested to connect with us, email us at cdenews@nus.edu.sg