Shinya OKUDA

Associate Professor (Educator Track)

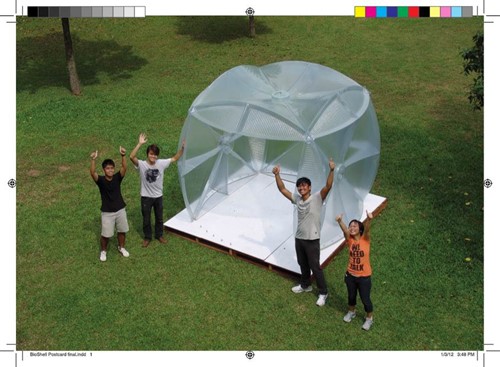

A/P Okuda is registered architect in Japan and EU, have practiced with Pritzker prize architects, such as Herzog & de Meuron in Switzerland and Shigeru Ban architects in Japan, prior to joining the NUS in 2008. A/P Okuda and his studios past projects include internationally patented Bio Shell (Biodegradable shelter, 2012), award-winning Cloud Arch (Ultra-light long-span structure, 2014), publicly acclaimed Groove Light project at i Light Marina Bay in Singapore (2016). A/P Okuda is appointed as Principal Investigator to develop one of the first Tropical Mass Timber Construction systems by Ministry of National Development, Singapore (Sky Timber project, 2016-). Honour received by A/P Okuda includes being the co-winner of Archifest Pavilion, Singapore (2014), a finalist of President’s Design Award for architecture, Singapore (2010), Excellence Award, Asian Design Awards, Hong Kong Designers Association, Hong Kong (2009), the 3rd prize at the International Advanced Architecture Competition, Barcelona, Spain (2007) among many others. He is one of the leaders of Advanced Architectonics Design Lab (AADL), also affiliated faculty to Future Cities Laboratory, ETHZ and Centre for Nature-based Climate Solutions, NUS.

For more information, please visit: https://www.skytimber.org.

PI: A/P Shinya Okuda Structural Consultant: Web Structures Pte Ltd / MNDRF Construction Productivity RD&D Grant, SDE Well and Green initiative fund / Feb 2019 - MAR 2021 The Book Bridge, a bookshelf made of the first-of-its-kind renewable tropical Mass Engineered Timber (MET) with a 3.138 m wide span shelf, standing at 30.942 metres in total length, is one of the central art pieces for the NUS Central Library transformation plan. It is made of 7 m3 of tropical MET, a renewable, sustainable material for architecture. In general, 1 m3 of timber could lock 1 ton of atmospheric Carbon Dioxide (CO2) in solid form. The Book Bridge demonstrates one of the first structural uses of the fast-growing tropical plantation timber, which grow approximately a few times faster than the ones in temperate climate, unless otherwise the current major usages include pulps and chips. The innovative H-section shelves are strategically designed with built-in camber to counter the effects of the calculated deflection. It also symbolizes one of NUS Central Library's missions, bridging knowledge, while it fills visitors' senses with serenity of the sustainable tropical forest.

Innovative Mass Timber Construction Systems for High-density Urban Environment in the Tropics PI: A/P Shinya Okuda, Co-PI: A/P Harn Wei Kua MNDRF / TPV S$538,344 / Sep 2016 – In-Progress In 2012, Singapore adopted Eurocode, and its performance-based assessment enabled one of the first mass-engineered timber constructions in Asia. Since then, several mass-engineered timber buildings have been constructed in Singapore, which lifted its height limitations in 2016. Currently, many other mass-timber projects are under planning locally; however, most projects are planned to use imported Cross-Laminated Timber or Glulam primarily from the Europe due to its Eurocode compliance. This will not be sustainable to repeatedly transport mass-engineered timber components over long distances, which may eventually erode the positive effect of carbon sequestration. Southeast Asia is blessed with some of the oldest forests in the world, which have supplied large volumes of wood-based products internationally. However, most use is limited to furniture, plywood, pulps and chips and not use as structural timber components. In addition, overall deforestation in the region has not yet stopped, notwithstanding increasing efforts by the local and international timber and forestry sectors. Due to year-round sunlight, some plantation species in the Tropics may grow roughly four times faster than those in a temperate climate. As such, we focus on fast-growing plantation species which may eventually have relatively weak mechanical properties on their own but which may become suitable for construction use if developed into mass-engineered timber components. REFERENCE: - SKY TIMBER: MASS TIMBER ARCHITECTURE IN THE TROPICS INTERNATIONAL WORKSHOP 2019 - SKYTIMBER: MASS TIMBER ARCHITECTURE IN THE TROPICS LECTURE SERIES 2018 - RENEWABLE TROPICAL ARCHITECTURE (NUS News)

Innovative EPS Composite for Ultra Lightweight Long Span Sustainable Structure PI: A/P Shinya Okuda, Co-PI: Prof. Tan Kiang Hwee. Collaborator: Web Structures NUS-JTC i3 Center / TPV: SGD 287,500 / Mar.2014 – Jun. 2017 Expanded Polystyrene foam (EPS) is a chemically inert and 100% recyclable material that is lightweight and has good compression strength per weight ratio; however, its current construction use is mostly limited to insulation or landfill. The key concept of this paper is to develop an EPS composite to create an ultra-lightweight long-span sustainable roofing structure by integrating the minimum necessary structural tension layer with a certified fire protection system. The authors present this concept in the following four steps, 1) EPS composite structural specimen test, 2) structural optimisation of the reversed displacement model, 3) discretisation with developable surfaces and 4) CNC hotwire rapid prototyping and assembly in scaled prototypes. The Cloud Arch is an economical, material-efficient, thermally insulated, quickly assembled ultra-lightweight construction that eliminates the need for formworks for long-span structures. It can be applied to many types of column-free spaces, such as in factories, gymnasiums, markets and cafeterias. Keywords. Lightweight; prototyping; composite; digital fabrication; performance.

Biodegradable Vacuum-formed Modular Shelter PI: A/P Shinya OKUDA TechConnect World Summit & Innovation Showcase 2012Santa Clara Convention Center, Santa Clara, CA, USA(US Patent No. US 2012/0318314 A1) This paper demonstrates how digitally fabricated vacuum-formed components can provide a new type of efficient construction applicable to architecture. Vacuum forming has the advantage of rapid mass-production capability of 3D curved forms. Recent digital fabrication technologies, such as 3D CAD and CNC machining, have dramatically reduced the cost and time for making the mould. In combination with biodegradable plastic, such as PLA (poly lactic acid) made of biopolymer, it could open up new type of sustainable construction system, which is applicable for temporal disaster housings or exhibition booths. Keywords. Digital fabrication; biodegradable; vacuum forming; finite element analysis; lightweight structure.

A/P Shinya OKUDA + 11 Year 4 students i Light Marina Bay SingaporeMay 2015 - Apr. 2016 Groove Light provokes new relationships between light and shadows in digital era. Five distinctively complex lanterns were designed and fabricated by integrating innovative designs, computational simulations and fabrication technologies. Each lantern produces identical geometric shadow when light is shone through. By moving the lanterns/light sources, visitors can interact with the dynamic geometric shadow scape created by the installation. Groove Light goes beyond green. Using biodegradable plastics, the recyclable 3D printed lanterns can be melted down and re-extruded as filament for next round of large-scale 3D printings. Keywords. Digital Physicality; 3D Printing; Projection Mapping; Additive Manufacturing; Parametric Design.