Professional Development Workshop

Overpressure Protection Design Principles

Jointly organized by:

Department of Chemical & Biomolecular Engineering, and NUS Alumni Safety, Health & Environment Society

Date: To be advised

Duration: 1 day, 0900 – 1800hr

Venue: NUS eLearning Platform

MOM-WSHO-SDU: 8 points

PEB-PE-PDU: 5 points

Registration date: To be advised

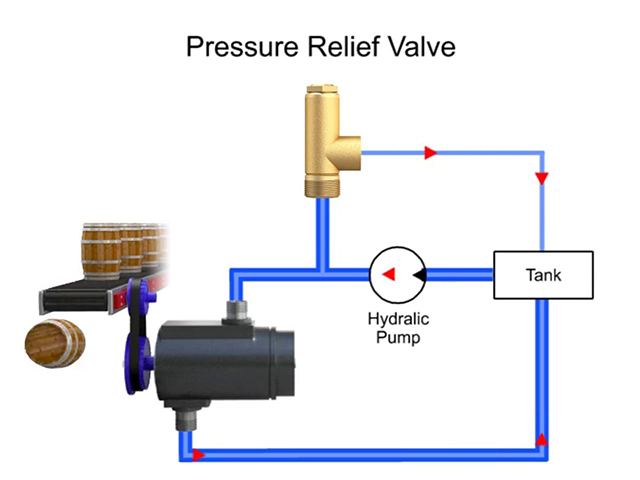

Overpressure protection objective:

Pressure relief devices (PRDs) protect equipment or piping from overpressure and low pressure hazards. The PRD operates by opening at a designated set pressure and by relieving the excess flowrate so that the pressure in the equipment or piping is maintained within its design conditions. If the PRD and its associated piping are not designed to relieve the excess flowrate or if the PRD fails to function on demand, there is a potential to overpressure and result in a loss of containment. In case of a loss of containment of flammable or toxic material, there is a potential for major accidents including vapor cloud explosions, fires or toxic exposure.

Course outline:

In this course, the participants will be guided on the overpressure protection design principles and design requirements. This course is designed to provide a focused guidance on the relief system design adequacy reviews. The course content includes analysis of overpressure scenarios, simple examples on the relief load calculations and relief device sizing. At the end of the course, the participants will have a knowledge and awareness on the fundamentals and first principles associated with the

- Overpressure protection design philosophy

- Overpressure protection design adequacy analyses

- Ability to identify credible overpressure scenarios

- Ability to understand the relief load calculations and relief device sizing

Who should attend?

Engineers involved in the Management of Change (MOC) reviews, process design and projects would greatly benefit by attending this course. In general, the course would be useful to process engineers, process designers, process safety engineers, project engineers from beginner to intermediate level.

Prerequisites:

Engineering background with a basic understanding on overpressure protection design requirements

Course content:

- Overview of concepts and principles

- Codes and Standards

- Design principles

- Types of relief devices

- Overpressure protection requirements

- Overpressure protection adequacy analyses

- Relief load calculations

- Relief device sizing

Fees:

S$1,530 subject to 8% GST. Singapore SkillsFuture Funding is not applicable.

20% discount for corporate group registrations (minimum two participants) and members of NUS Alumni Safety, Health & Environment Society.

For further enquiries, please email cheers@nus.edu.sg.

Trainer’s Profile

Er. Premkumar

Er. Premkumar

Process Safety Specialist

ALARP Process Safety Solutions

Premkumar is a process safety specialist with hands-on experience in process safety, process design, process engineering and plant operations. He is a chemical engineer with 23 years of process industry experience in petroleum refining, petrochemicals, chemicals, oil & gas and industrial gases sectors across Asia Pacific, New Zealand and India. He is an IChemE registered Professional Process Safety Engineer and a Professional Engineer (Chemical) registered in Singapore. He has a well-rounded international experience in the operating, engineering and consulting environments.

Prior to his current role, Prem worked for multinational companies including ExxonMobil, Chevron, Air Products, Jacobs Engineering and WorleyParsons. He handled a regional process safety specialist role and provided process safety & risk engineering support to the existing operating facilities and capital projects (up to US$700MM) across Asia Pacific region. Prem handled a regional subject matter expert role for overpressure protection design and analysis. During his early career, he personally performed relief load calculations, relief device sizing and flare header sizing calculations.

Prior to his current role, Prem worked for multinational companies including ExxonMobil, Chevron, Air Products, Jacobs Engineering and WorleyParsons. He handled a regional process safety specialist role and provided process safety & risk engineering support to the existing operating facilities and capital projects (up to US$700MM) across Asia Pacific region. Prem handled a regional subject matter expert role for overpressure protection design and analysis. During his early career, he personally performed relief load calculations, relief device sizing and flare header sizing calculations.

He chaired several workshops on HAZID, HAZOP, SIL classification, risk assessments, bowtie reviews, LOPA and ALARP demonstration. He led and successfully completed specialised process safety studies such as Occupied Building Risk Assessments (OBRAs), overpressure protection studies and fire safety studies. He assisted major hazard installations in New Zealand and Singapore in their Safety Case development. He is an accomplished trainer for the process safety & risk training courses. More recently, he has been assisting his clients on the Dust Hazard Analysis (DHA) facilitation.