- Deposition and Growth

- Annealing Process

- Magnetic Processing

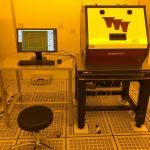

- Lithography

- Electron Beam Lithography – Ellionix

- Laser Writer – Hiedelberg (Class 10)

- Microwriter- Durham Magneto Optics Ml3 Pro (Class 10)

- Mask Aligner MA8 (Class 100)

- Mask Aligner MA6 (Class 10K)

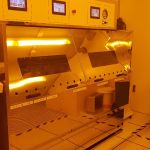

- Wet Processing (Class 10K)

- Solvent Wet Bench (Class 10)

- Spin Coater (Class 100)

- Hot Plate (Class 10)

- Baking Oven (Class 10K)

- Etching

- BEOL and Packaging

- Characterisation and Metrology

- Others

- Tool Booking

- Nano-and-Micro mix and match integration.

- Full flow technology prototyping comprising 100 to 200 steps supported by 30 to 40 tools.

- The 8” wafer capability enables the prototypes to easily scale up to the production level.

NANO FABRICATION AND PROCESS CAPABILITY

E6NanoFab enables the creation of nanoscale structures and devices with top-down and bottom-up approaches. The facility is equipped to provide maximum flexibility with capabilities to process a variety of materials such as CMOS compatible materials, magnetic materials, III-V & III-N materials, 2D materials and flexible materials.

THIN FILM DEPOSITION and MATERIAL GROWTH

ANNEALING PROCESS

MAGNETIC PROCESSING

LITHOGRAPHY

Lithography is a process where a pattern written or transferred to a substrate. It uses light, ions or electron energy into photo and electron sensitive resists. At E6NanoFab, Electron-Beam Lithography, Laser-Writer, and Mask-Aligner tools serve to pattern a variety of materials from sub-10 nanometers up to 100’s of microns over large sample areas.

ETCHING

Etching is a process for pattern transfer and surface treatment in micro-nano device fabrication. E6NanoFab makes available dry and wet etching systems to support the diverse process requirement.

Dry Etching

Multi-chamber cluster tools such as ICP plasma etching and ion beam milling provide strong dry etching capabilities for various materials such as Si, III-V & III-N, oxides, metals, polymers and others.

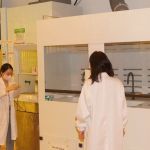

Wet Etching

Our dedicated wet-benches support several wet processes such as RCA, standard cleaning, and orientation dependent Si KOH etching.

BEOL & PAckaging

The last mile of the nanofabrication process.