[This article first appeared on NUS Engineering.]

Metals are some of the most widely used materials in the world, found in everything from cookware to computers. Every day metal waste is produced, from scrap metal in manufacturing to metal content in discarded old electronics.

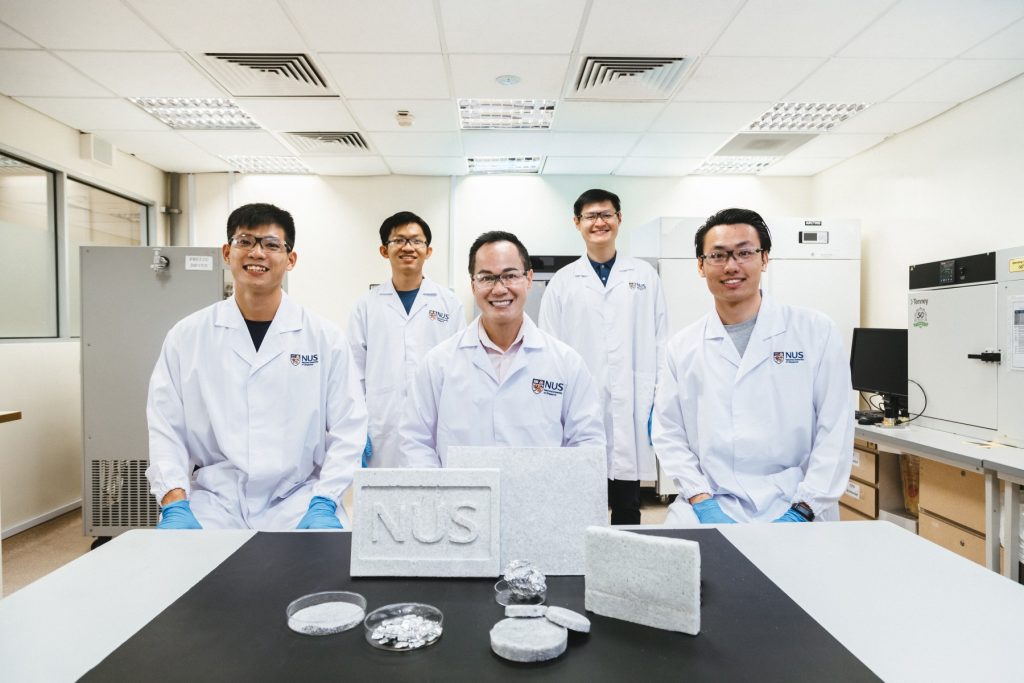

As a step towards mitigating the environmental impact of metal waste, a research team at NUS Engineering led by Associate Professor Duong Hai-Minh (Mechanical Engineering) has demonstrated a new eco-friendly technique to convert aluminium and magnesium waste into high-value aerogels with many applications. Their upcycling technique can potentially be extended to all types of metal waste in powder form.

“Our approach is cheaper, does not produce any hazardous waste, consumes less energy and is more environmentally-friendly than conventional recycling methods for metal waste,” says Prof Duong, who has previously produced aerogels from coffee grounds, scrap rubber, pineapple leaves, and other waste materials.

Like other forms of aerogels, these metal aerogels are effective heat and sound insulators, but also have a range of other properties and possible applications.

By incorporating optical fibres into the aerogel recipe, they have also made translucent aluminium aerogel that is six times lighter and 120 times cheaper than translucent concrete (LiTraCon).

And they are looking into possible biomedical applications for the aluminium aerogels as microcarriers – micro-sized beads for cells to grow on.

Read more about the team’s metal aerogels and their potential uses at NUS News