Advanced Manufacturing

Singapore RIE2020 plan identified Advanced Manufacturing and Engineering as a priority area. The Department of Mechanical Engineering (ME) is fronting the ‘NUS Future of Manufacturing Initiative’. Core themes of this initiative include:

- ICT advances for manufacturing,

- robotics and industrialization of manufacturing processes,

- Additive manufacturing/3D Printing, and

- advances in materials and materials systems ICT.

The initiative has ~50 faculty members drawn primarily from ME department and other departments, schools and faculties of NUS. The department has established a strong partnership with SIMTech, A*Star. Specific goals of this effort are:

- to establish local competence in future manufacturing skills, and

- to innovate manufacturing suitable for coordination and running of regional manufacturing and mass customization of products.

The AM focus at ME are centred around the process and material developments for future/digital manufacturing with design-centric innovations incl. design for AM, light weight structure for AM, process optimisation and simulation for AM, functional printing for industry applications, biomedical translational research, etc.

Highlights of research grants

| Research Grant | 3D Printing of Nitinol Stent for Medical Applications – funded by NRF (NAMIC), project duration is from May 2018 to May 2020. |

| Funding amount: approx. SG$249,600 | |

| Principle Investigator (PI): Professor Jerry Fuh, Co-PI: Associate Professor Lu Wenfeng | |

| Research Grant | 3D Printing of Low Elastic Modulus Titanium Parts with Interconnected Pore Structures Targeting Implant Applications – funded by NRF (NAMIC),project duration from Jan 2018 to Jan 2020. |

| Funding amount: approx. SG$240,000 | |

| PI: Associate Professor Senthil Kumar A | |

| Research Grant | Fabrication of 3D Conductive Scaffolds for Tissue Engineering – funded by Ministry of Education (MOE), project duration is from March 2017 and Feb 2020. |

| Funding amount: approx. SG$160,000 | |

| PI is Associate Professor Lu Wenfeng and Co-PI is Professor Jerry Fuh. | |

| Research Grant | Feasibility Study and Characterization of 3D Printable Ceramic Materials-CM301: Process & Materials – funded by Morgan Ceramics Asia Pte Ltd, project duration is from March 2015 to Feb 2017. |

| Funding amount: approx. SG$258,000 | |

| PI is Professor Jerry Fuh and Co-PI is Professor Ding Jun |

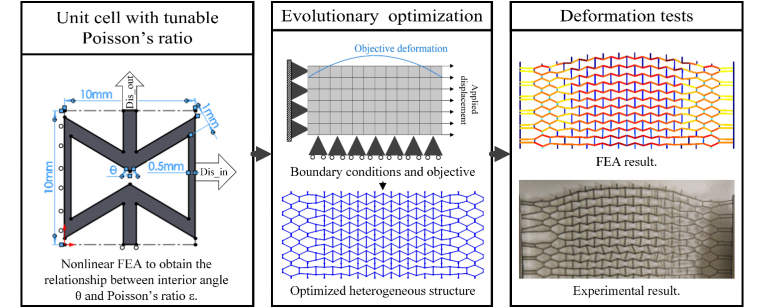

Design and optimization of lightweight cellular structures with additive manufacturing

AR-FEA for Engineering Analysis of Structures

AR-FEA integrates finite element analysis (FEA) and augmented reality (AR) technology to marry the powerful features of these two technologies so as to provide an intuitive and context-aware visualization interface for engineering design and analysis of structures on-site. AR-FEA allows FEA simulation, scientific visualization and real elements to co-exist in a physical scene. Sensors measurements are transmitted in real-time to update the FEA results that can be visualized directly on real world objects and this allows users to analyze the practical problems on-site.

Contact:

Ong Soh Khim

Associate Professor

Email: mpeongsk@nus.edu.sg

AR-based 3D Bare-hand Interaction

Bare hand interaction is an human-computer interaction method. ARBHI allows users to interact with both virtual and real objects in the AR environment directly and intuitively. ARBHI is adaptable to different light conditions and backgrounds, and hence it is suitable for real-time applications. It can detect and differentiate left and right hands in the AR-based environment. Users can inspect, manipulate and interact with 3D virtual objects naturally, e.g., assembly virtual objects together, or assembly a virtual object to a real object.

Contact:

Ong Soh Khim

Associate Professor

Email: mpeongsk@nus.edu.sg

Collaborative AR 3D Visualization and Annotation

The CAR3VA platform provides 3D product/process visualisation and annotation. Users can perform annotation of real physical products/processes with detailed manufacturing information, and visualise exploded view of these products and processes in 3D space. It allows users, either co-located or geographically located, to collaborate and interact with virtual and real entities in a common AR-based visualisation environment. Thus, it enhances communication between various stakeholders during the product and process development.